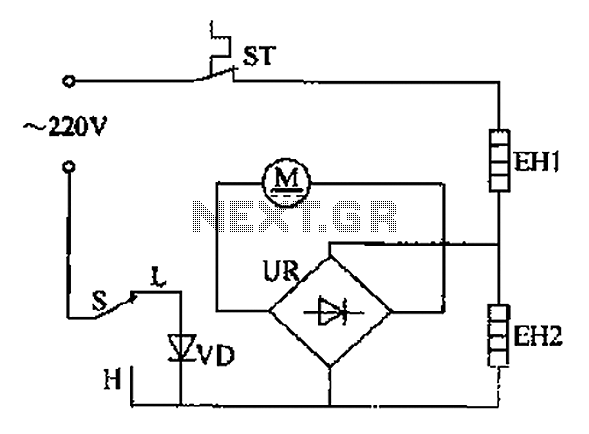

Comb electric circuit

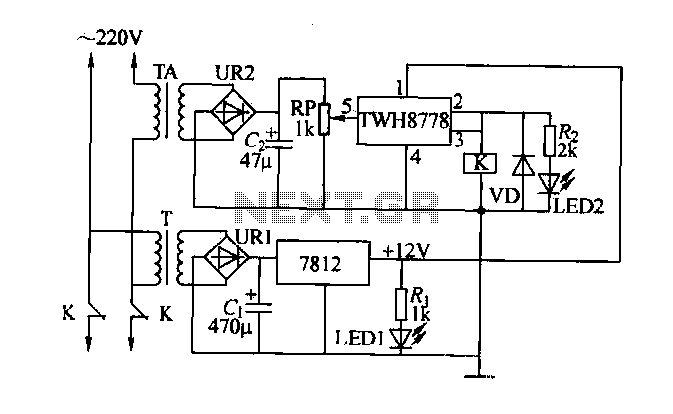

The comb electric circuit illustrated in Figure 1-3 features two temperature settings. By toggling switch S to either the L or H position, different temperatures can be achieved. Once switch S is activated, the circuit powers the heating wires EH1 or EH2. Following the rectification process, the 220V alternating current is converted into direct current, enabling a small DC motor M to operate. The generated heat is then utilized for styling hair.

The comb electric circuit operates by utilizing a dual-temperature control system, allowing users to select between low (L) and high (H) temperature profiles via switch S. This functionality is critical for accommodating various hair types and styling needs. When the switch is engaged, current flows through the heating elements, EH1 or EH2, which are strategically positioned to efficiently transfer heat to the hair.

The circuit employs a rectifier to convert the incoming 220V AC supply into a stable DC output. This rectification is essential for powering the small DC motor M, which drives the mechanical components of the comb. The motor's rotation is synchronized with the heating elements, ensuring that heat is applied consistently during the styling process.

The heating wires are designed to reach the desired temperature quickly, thanks to their low thermal mass and high conductivity. The circuit may also include thermal protection features to prevent overheating, ensuring safety during operation. Additionally, an LED indicator may be incorporated to signal when the device is powered on and heating.

Overall, this comb electric circuit exemplifies a practical application of electronics in personal grooming devices, combining heating and mechanical motion to facilitate effective hair styling. Comb electric circuit shown in Figure 1-3. It has two temperature options, switch S into L or H profile file, you can get different temperatures. Then later on switch S, the ci rcuit is turned on, the heating wire EH1 or EH2 heating, after UR rectification, the 220v alternating current into direct current, so that a small DC motor M is rotated. Heat into the hair, to shaping hair.

The comb electric circuit operates by utilizing a dual-temperature control system, allowing users to select between low (L) and high (H) temperature profiles via switch S. This functionality is critical for accommodating various hair types and styling needs. When the switch is engaged, current flows through the heating elements, EH1 or EH2, which are strategically positioned to efficiently transfer heat to the hair.

The circuit employs a rectifier to convert the incoming 220V AC supply into a stable DC output. This rectification is essential for powering the small DC motor M, which drives the mechanical components of the comb. The motor's rotation is synchronized with the heating elements, ensuring that heat is applied consistently during the styling process.

The heating wires are designed to reach the desired temperature quickly, thanks to their low thermal mass and high conductivity. The circuit may also include thermal protection features to prevent overheating, ensuring safety during operation. Additionally, an LED indicator may be incorporated to signal when the device is powered on and heating.

Overall, this comb electric circuit exemplifies a practical application of electronics in personal grooming devices, combining heating and mechanical motion to facilitate effective hair styling. Comb electric circuit shown in Figure 1-3. It has two temperature options, switch S into L or H profile file, you can get different temperatures. Then later on switch S, the ci rcuit is turned on, the heating wire EH1 or EH2 heating, after UR rectification, the 220v alternating current into direct current, so that a small DC motor M is rotated. Heat into the hair, to shaping hair.