DC Motor Speed Controller

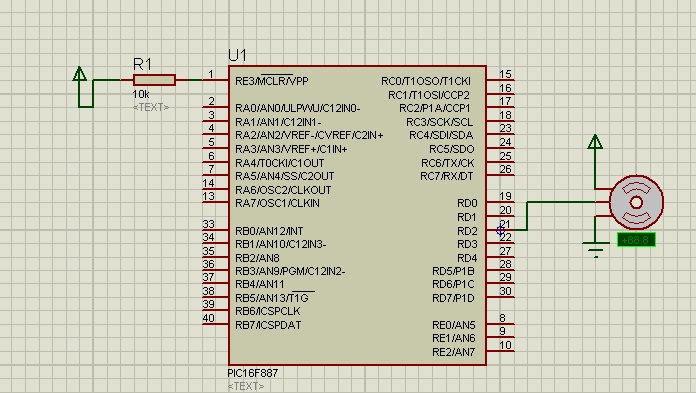

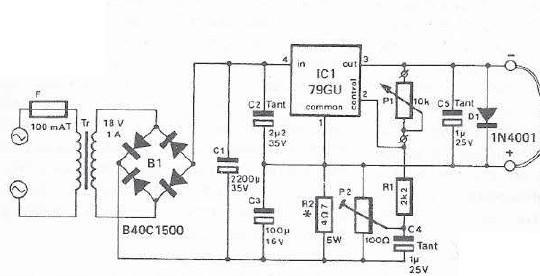

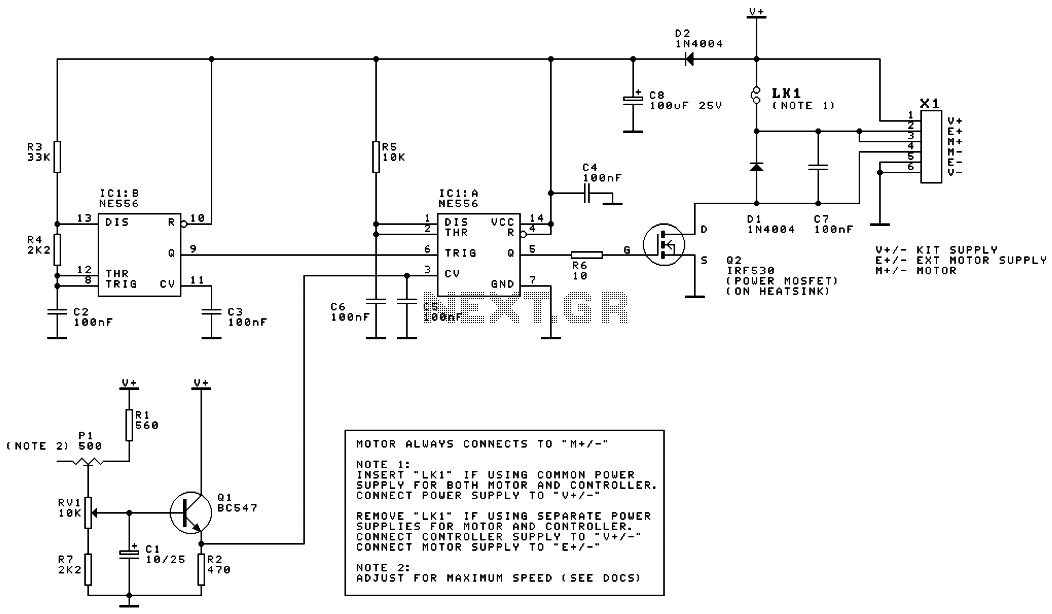

This is the schematic diagram of a DC motor speed controller circuit. The circuit utilizes two oscillators/timers that are configured as a Pulse Width Modulator (PWM). The timer chip used in this circuit is a dual NMOS timer/oscillator.

The DC motor speed controller circuit employs a dual timer configuration to generate PWM signals that control the speed of a DC motor. The two oscillators work in tandem, producing a variable duty cycle output that modulates the average voltage supplied to the motor, effectively controlling its speed.

The circuit typically consists of a 555 timer IC or a similar dual timer chip, which is configured in astable mode to generate the PWM signal. The output from the timer is fed into a transistor or MOSFET, which acts as a switch to control the power delivered to the motor. The duty cycle of the PWM signal can be adjusted by varying the resistances and capacitance in the timer circuit, allowing for fine control over the motor speed.

In addition to the timer and switching components, the circuit may also include additional elements such as diodes for flyback protection, capacitors for filtering, and resistors for setting the timing parameters. The inclusion of these components ensures stable operation and protects against voltage spikes that can occur when the motor is turned off.

Overall, this DC motor speed controller circuit is an efficient solution for applications requiring variable speed control, such as in robotics, conveyor systems, and various automated machinery. The use of PWM not only enhances the control over the motor speed but also improves energy efficiency compared to other control methods.This is the schematic diagram of DC motor speed controller circuit. The circuit applies two oscillators/timers which are connected as a Pulse Width Modulator (PWM). The timer chip which applied in this circuit will be an nmos dual timer/osc.. 🔗 External reference

The DC motor speed controller circuit employs a dual timer configuration to generate PWM signals that control the speed of a DC motor. The two oscillators work in tandem, producing a variable duty cycle output that modulates the average voltage supplied to the motor, effectively controlling its speed.

The circuit typically consists of a 555 timer IC or a similar dual timer chip, which is configured in astable mode to generate the PWM signal. The output from the timer is fed into a transistor or MOSFET, which acts as a switch to control the power delivered to the motor. The duty cycle of the PWM signal can be adjusted by varying the resistances and capacitance in the timer circuit, allowing for fine control over the motor speed.

In addition to the timer and switching components, the circuit may also include additional elements such as diodes for flyback protection, capacitors for filtering, and resistors for setting the timing parameters. The inclusion of these components ensures stable operation and protects against voltage spikes that can occur when the motor is turned off.

Overall, this DC motor speed controller circuit is an efficient solution for applications requiring variable speed control, such as in robotics, conveyor systems, and various automated machinery. The use of PWM not only enhances the control over the motor speed but also improves energy efficiency compared to other control methods.This is the schematic diagram of DC motor speed controller circuit. The circuit applies two oscillators/timers which are connected as a Pulse Width Modulator (PWM). The timer chip which applied in this circuit will be an nmos dual timer/osc.. 🔗 External reference