EMP Generator Schematic

These are plans for an EMP generator. It utilizes flash circuits from disposable cameras to power the coil. An instructable will be created soon.

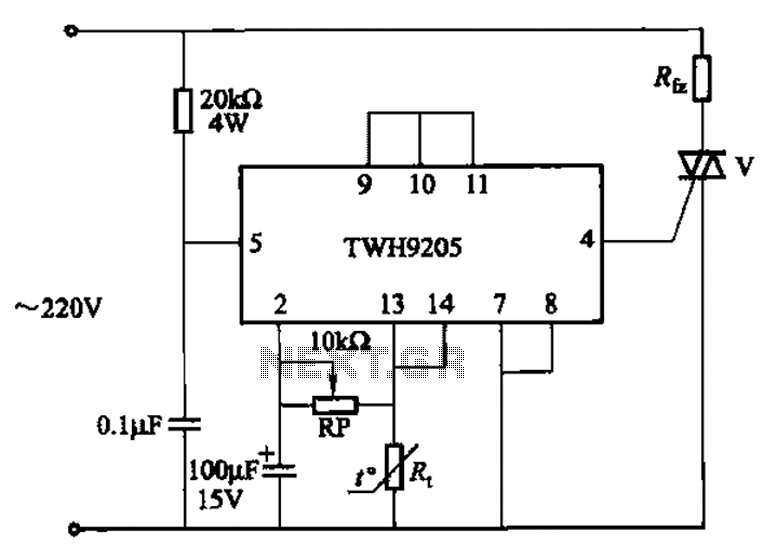

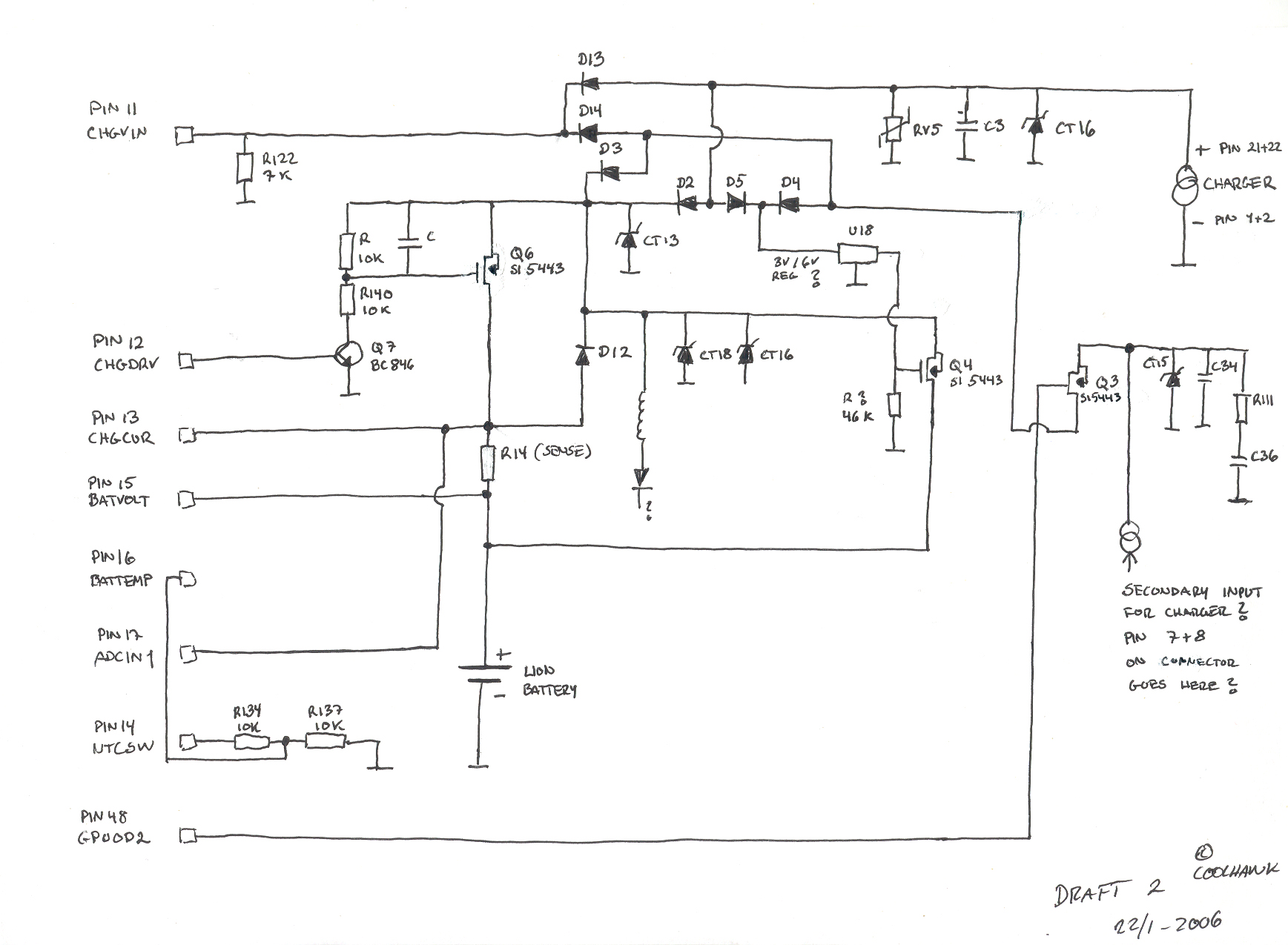

The EMP generator design described involves utilizing the high-voltage flash circuits found in disposable cameras. These circuits are capable of generating a significant voltage, typically in the range of 300 to 400 volts, which is suitable for creating an electromagnetic pulse (EMP) effect. The basic components of the circuit include a capacitor, a transformer, and a discharge coil.

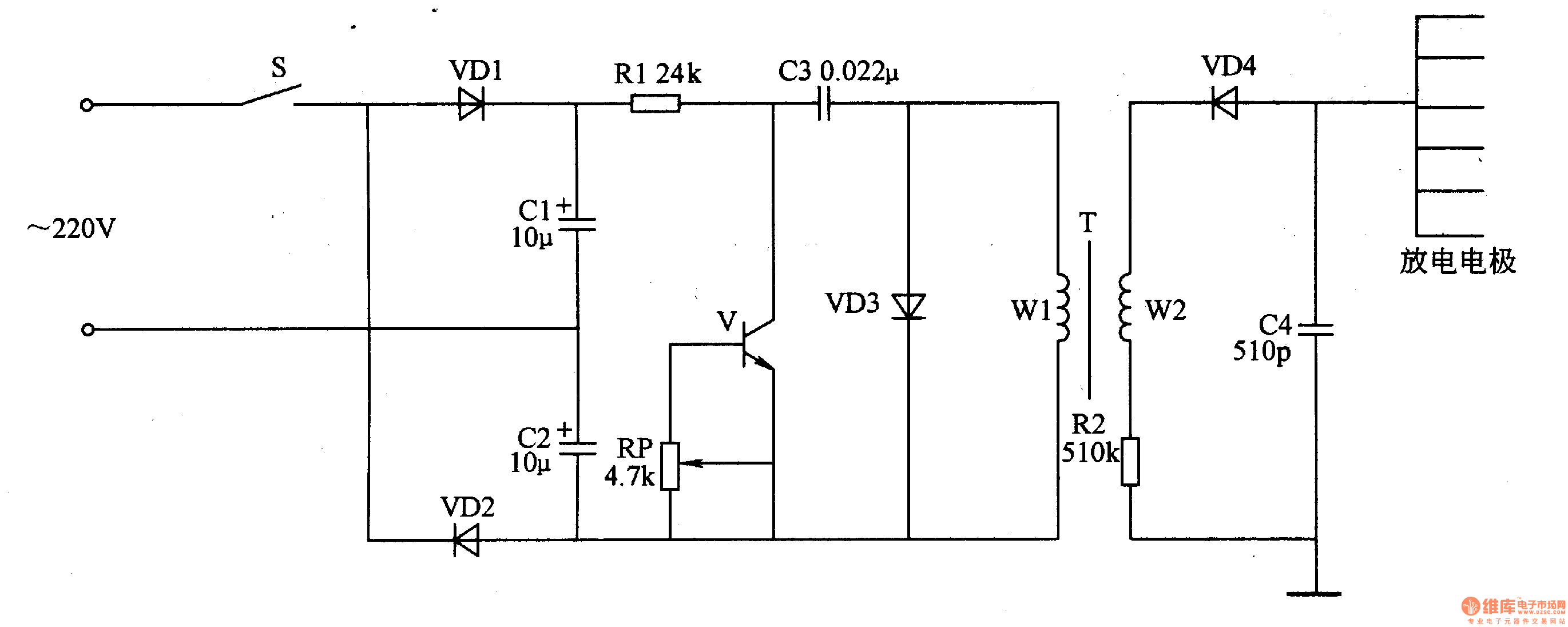

The disposable camera flash circuit operates by charging a capacitor through a low-voltage power supply, which is usually a small battery. Once the capacitor reaches its maximum charge, the circuit triggers the flash mechanism, discharging the stored energy through a transformer. This transformer steps up the voltage to a much higher level, which is then delivered to the discharge coil.

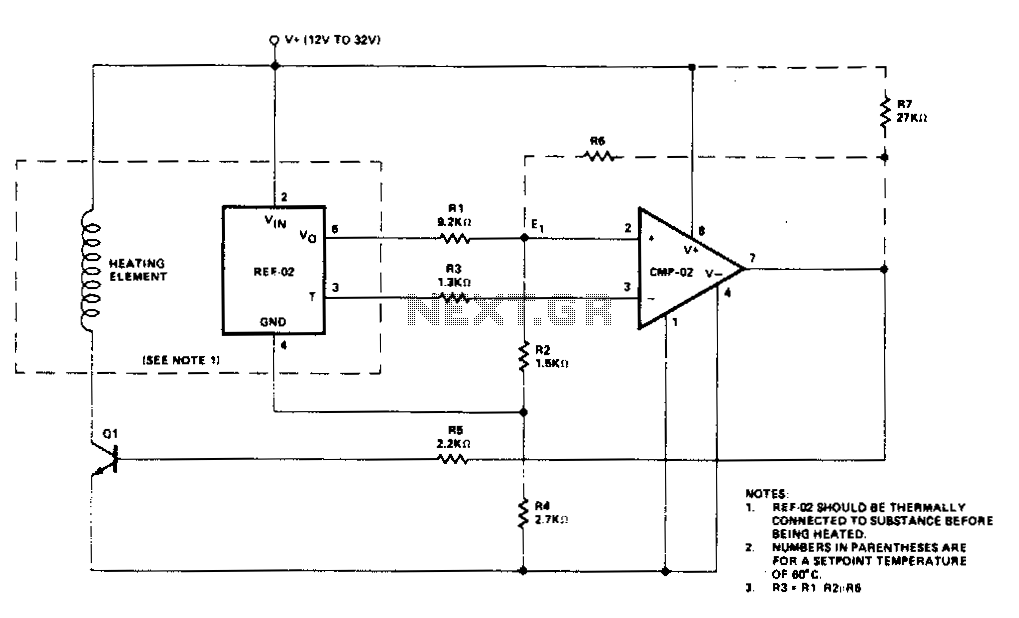

The discharge coil is a critical component of the EMP generator. It is designed to create a rapidly changing magnetic field when energized. The design of the coil, including the number of turns and the wire gauge, will significantly affect the efficiency and effectiveness of the EMP produced. A larger coil with more turns will typically generate a stronger magnetic field, leading to a more pronounced EMP effect.

Safety precautions are essential when working with high-voltage circuits, as the components can pose serious risks. Proper insulation, the use of protective gear, and adherence to safety guidelines are imperative when assembling and testing the EMP generator.

The instructable planned for this project will provide step-by-step guidance on the construction process, including a list of materials, circuit diagrams, and safety tips. This will enable individuals interested in replicating the design to do so while understanding the underlying principles and potential hazards associated with high-voltage electronics.These are my plans for an EMP Generator. It uses flash circuits from disposable cameras to power the coil. I plan to make an instructable of it soon.. 🔗 External reference

The EMP generator design described involves utilizing the high-voltage flash circuits found in disposable cameras. These circuits are capable of generating a significant voltage, typically in the range of 300 to 400 volts, which is suitable for creating an electromagnetic pulse (EMP) effect. The basic components of the circuit include a capacitor, a transformer, and a discharge coil.

The disposable camera flash circuit operates by charging a capacitor through a low-voltage power supply, which is usually a small battery. Once the capacitor reaches its maximum charge, the circuit triggers the flash mechanism, discharging the stored energy through a transformer. This transformer steps up the voltage to a much higher level, which is then delivered to the discharge coil.

The discharge coil is a critical component of the EMP generator. It is designed to create a rapidly changing magnetic field when energized. The design of the coil, including the number of turns and the wire gauge, will significantly affect the efficiency and effectiveness of the EMP produced. A larger coil with more turns will typically generate a stronger magnetic field, leading to a more pronounced EMP effect.

Safety precautions are essential when working with high-voltage circuits, as the components can pose serious risks. Proper insulation, the use of protective gear, and adherence to safety guidelines are imperative when assembling and testing the EMP generator.

The instructable planned for this project will provide step-by-step guidance on the construction process, including a list of materials, circuit diagrams, and safety tips. This will enable individuals interested in replicating the design to do so while understanding the underlying principles and potential hazards associated with high-voltage electronics.These are my plans for an EMP Generator. It uses flash circuits from disposable cameras to power the coil. I plan to make an instructable of it soon.. 🔗 External reference