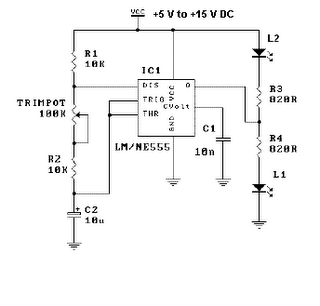

heatsink temperature monitor circuit

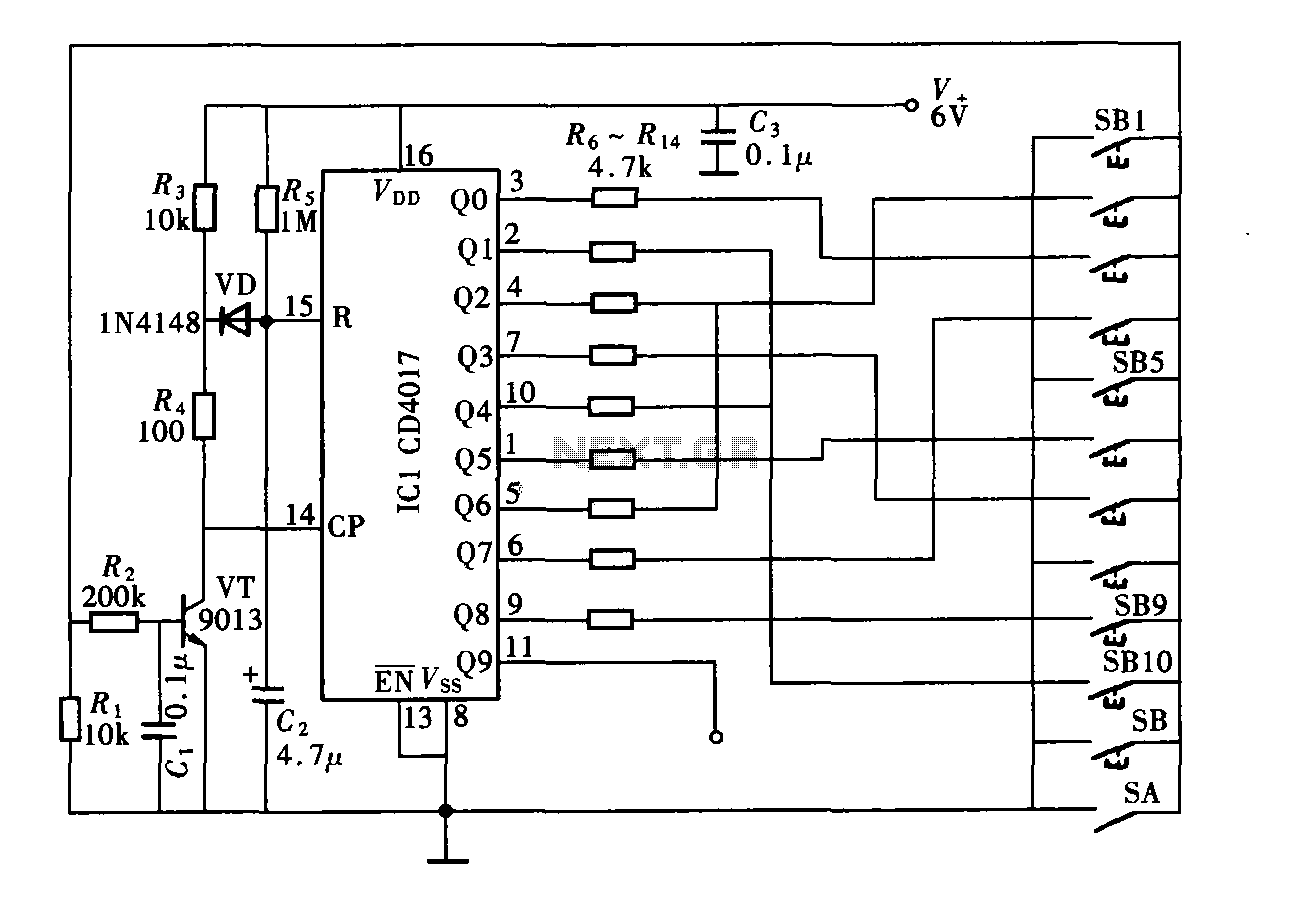

This heatsink temperature monitor circuit uses three LEDs to signal when the temperature exceeds two boundary levels. When the heatsink temperature is below 50-60°C (122-140°F), the green LED lights up. The yellow LED indicates that the temperature is between 60-70°C (140-158°F). The red LED signals that the temperature has surpassed 70°C (158°F). At this point, a relay can be activated to disconnect the power supply or protect the electronic device by turning on a cooling fan. As depicted in the circuit diagram, the heatsink monitor consists of two operational amplifiers configured as window comparators. The input voltage level is determined by the thermosensor IC LM335, which produces a voltage that increases linearly by 10mV/°C. If this voltage is below the levels set by potentiometers P1 and P2, the outputs of the op-amps are nearly at ground potential (0V), illuminating the green LED. To establish the desired temperature thresholds, the LM335 thermosensor should be placed in a pot of water that is being gradually heated. Set P1 to its minimum and P2 to its maximum. The transition from the green LED to the yellow (50-60°C) is adjusted with P1, while the transition from yellow to red is controlled by P2. The thermometer should be monitored as the water heats, and the potentiometers should be fine-tuned accordingly. Once the desired temperature settings are achieved, the thermosensor can be affixed to the heatsink.

This heatsink temperature monitor circuit serves as an efficient thermal management solution for electronic devices. The use of three distinct LEDs allows for clear visual feedback regarding the temperature status of the heatsink, facilitating immediate recognition of potential overheating conditions. The green LED indicates a safe operating range, while the yellow and red LEDs serve as warnings for increasing temperature thresholds.

The core of the circuit relies on two operational amplifiers configured as window comparators. This configuration is ideal for monitoring specific voltage levels, which correspond to the temperature ranges defined by the LM335 thermosensor. The LM335 is a precision temperature sensor that outputs a voltage proportional to the temperature, allowing for accurate monitoring. The choice of 10mV/°C sensitivity ensures that small temperature variations can be detected, which is critical for maintaining the integrity of sensitive electronic components.

Potentiometers P1 and P2 provide adjustable reference voltages for the operational amplifiers, enabling customization of the temperature thresholds. This adjustability is particularly beneficial in applications where different components may have varying thermal tolerances. The calibration process, involving immersion of the thermosensor in heated water, ensures that the circuit is accurately set to the desired temperature points before deployment.

In addition to the visual signals provided by the LEDs, the circuit also incorporates a relay mechanism that can be utilized to either disconnect the power supply or activate a cooling fan when the temperature exceeds the red threshold. This feature adds an additional layer of protection, ensuring that the electronic device operates within safe thermal limits.

Overall, this heatsink temperature monitor circuit exemplifies a practical and effective approach to thermal management in electronics, combining visual indicators with automatic control mechanisms to enhance device reliability and performance.This heatsink temperature monitor circuit signals via 3 LEDs when the temperature exceeds 2 boundary levels. When the heatsink temperature is below 50 60oC (122 140oF) the greed LED lights. The yellow one signals that the temperature is within 60 and 70oC (140 158oF). The red one signals that the temperature has reached beyond 70 8 0o (158 176oF). At this point a relay can be triggered to break the power supply or otherwise protect the electronic device by turning ON a cooling fan. As shown in the circuit diagram the heatsink monitor is made of 2 opamps that are set as window comparators.

The input voltage level is set by the thermosensor IC LM335. This voltage level increses linearly by a factor of 10mV/oC. If this voltage is below the voltage level set by P1 and P2, the opamp outputs are almost at ground potential (0V) and the green LED lights up. To set the desired temperature levels: put the thermosensor LM355 together with a thermometer into a pot of water which is being heated slowly.

Turn P1 to its lowest point and turn P2 to its maximum. The switching point from green LED to yellow (50 60oC) is set with P1. The switching point from yellow to red is set withh P2. Watch thermometer while the water is being heated and adjust the potentiometers accordingly. Once the desired values are set, attach the thermosensor to the heatsink. 🔗 External reference

This heatsink temperature monitor circuit serves as an efficient thermal management solution for electronic devices. The use of three distinct LEDs allows for clear visual feedback regarding the temperature status of the heatsink, facilitating immediate recognition of potential overheating conditions. The green LED indicates a safe operating range, while the yellow and red LEDs serve as warnings for increasing temperature thresholds.

The core of the circuit relies on two operational amplifiers configured as window comparators. This configuration is ideal for monitoring specific voltage levels, which correspond to the temperature ranges defined by the LM335 thermosensor. The LM335 is a precision temperature sensor that outputs a voltage proportional to the temperature, allowing for accurate monitoring. The choice of 10mV/°C sensitivity ensures that small temperature variations can be detected, which is critical for maintaining the integrity of sensitive electronic components.

Potentiometers P1 and P2 provide adjustable reference voltages for the operational amplifiers, enabling customization of the temperature thresholds. This adjustability is particularly beneficial in applications where different components may have varying thermal tolerances. The calibration process, involving immersion of the thermosensor in heated water, ensures that the circuit is accurately set to the desired temperature points before deployment.

In addition to the visual signals provided by the LEDs, the circuit also incorporates a relay mechanism that can be utilized to either disconnect the power supply or activate a cooling fan when the temperature exceeds the red threshold. This feature adds an additional layer of protection, ensuring that the electronic device operates within safe thermal limits.

Overall, this heatsink temperature monitor circuit exemplifies a practical and effective approach to thermal management in electronics, combining visual indicators with automatic control mechanisms to enhance device reliability and performance.This heatsink temperature monitor circuit signals via 3 LEDs when the temperature exceeds 2 boundary levels. When the heatsink temperature is below 50 60oC (122 140oF) the greed LED lights. The yellow one signals that the temperature is within 60 and 70oC (140 158oF). The red one signals that the temperature has reached beyond 70 8 0o (158 176oF). At this point a relay can be triggered to break the power supply or otherwise protect the electronic device by turning ON a cooling fan. As shown in the circuit diagram the heatsink monitor is made of 2 opamps that are set as window comparators.

The input voltage level is set by the thermosensor IC LM335. This voltage level increses linearly by a factor of 10mV/oC. If this voltage is below the voltage level set by P1 and P2, the opamp outputs are almost at ground potential (0V) and the green LED lights up. To set the desired temperature levels: put the thermosensor LM355 together with a thermometer into a pot of water which is being heated slowly.

Turn P1 to its lowest point and turn P2 to its maximum. The switching point from green LED to yellow (50 60oC) is set with P1. The switching point from yellow to red is set withh P2. Watch thermometer while the water is being heated and adjust the potentiometers accordingly. Once the desired values are set, attach the thermosensor to the heatsink. 🔗 External reference