ir remote control tester

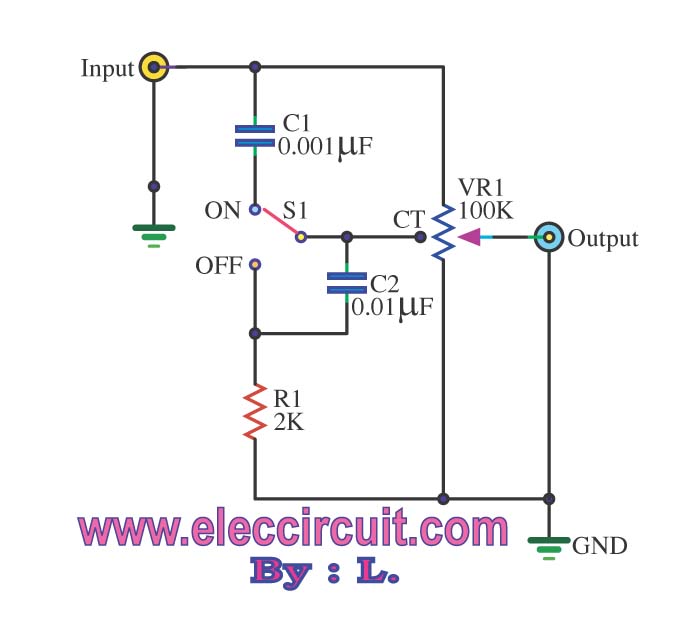

This compact circuit is designed to verify the basic functionality of an infrared remote control unit. It operates on the straightforward principle of connecting a piezo buzzer directly to an infrared (IR) receiver integrated circuit (IC). This approach is comparable to connecting a photodiode directly to an oscilloscope, yet it offers the benefit of eliminating the need for an oscilloscope. As a result, the small unit is always ready for use and is significantly more portable than traditional bulky testing equipment.

The circuit consists of a few key components: an IR receiver IC, a piezo buzzer, and supporting passive components such as resistors and capacitors. The IR receiver IC detects infrared signals emitted by the remote control. When the remote is activated, it sends out a modulated IR signal that the receiver IC picks up. The output of the IR receiver IC is a digital signal that indicates whether the IR signal is present.

The piezo buzzer serves as an auditory indicator of the circuit's operation. When the IR receiver detects a signal, it activates the buzzer, producing a sound that confirms the receipt of the infrared command. This immediate feedback allows users to quickly ascertain whether the remote control is functioning correctly.

In terms of power requirements, the circuit typically operates on low voltage, making it suitable for battery operation. The design emphasizes simplicity and accessibility, allowing users to test remote controls without the need for complex setups or additional testing devices.

Overall, this small circuit is an effective and user-friendly solution for testing infrared remote controls, offering portability and ease of use in a variety of settings.This small circuit is ideal for checking the basic operation of an infrared remote control unit. The circuit is based on the brilliantly simple idea of connecting a piezo buzzer directly to an IR receiver IC. This method is almost as simple as connecting a photodiode directly to the input of an oscilloscope, but has the advantage that no oscilloscope is needed: the compact unit is always ready to use and much easier to carry around than bulky test equipment..

🔗 External reference

The circuit consists of a few key components: an IR receiver IC, a piezo buzzer, and supporting passive components such as resistors and capacitors. The IR receiver IC detects infrared signals emitted by the remote control. When the remote is activated, it sends out a modulated IR signal that the receiver IC picks up. The output of the IR receiver IC is a digital signal that indicates whether the IR signal is present.

The piezo buzzer serves as an auditory indicator of the circuit's operation. When the IR receiver detects a signal, it activates the buzzer, producing a sound that confirms the receipt of the infrared command. This immediate feedback allows users to quickly ascertain whether the remote control is functioning correctly.

In terms of power requirements, the circuit typically operates on low voltage, making it suitable for battery operation. The design emphasizes simplicity and accessibility, allowing users to test remote controls without the need for complex setups or additional testing devices.

Overall, this small circuit is an effective and user-friendly solution for testing infrared remote controls, offering portability and ease of use in a variety of settings.This small circuit is ideal for checking the basic operation of an infrared remote control unit. The circuit is based on the brilliantly simple idea of connecting a piezo buzzer directly to an IR receiver IC. This method is almost as simple as connecting a photodiode directly to the input of an oscilloscope, but has the advantage that no oscilloscope is needed: the compact unit is always ready to use and much easier to carry around than bulky test equipment..

🔗 External reference