LED3X Solar Tracker Assembly

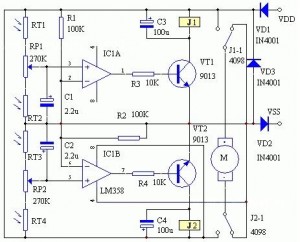

The table provided is useful for determining the capabilities of the MOSFETs across various versions. However, the connectors used in the LED3X "c" series are not rated for high continuous currents; they are technically rated for 7 amps. While 10 amps is manageable if applied intermittently, higher currents can be tolerated if the pulses are short. An experiment was conducted using a 12V automotive door window motor, which draws approximately 4 amps at 13.8V. The voltage was increased to 44V with a pulse width of about 1 second out of an 18-second cycle time, resulting in a peak current of 55 amps for 0.5 seconds, while keeping the components reasonably cool. The LED3X series Tracker PC boards utilize through-hole components, which are easier to assemble compared to the surface mount parts in the previous LED3 tracker. Assembly should follow a specific order to minimize damage risks from solder shorts or misplaced components. The components are sensitive to static discharges, so standard static discharge prevention methods should be employed, including a grounded workbench, soldering iron, and personal grounding wrist straps. The large mounting hole is connected to the negative power terminal and should be the first point of contact when handling the circuit until the connector is installed. The term "Tack Solder" refers to soldering one lead of a component on the top side of the board. Components are arranged so that one easily accessible lead is positioned nearest to the mounting hole. Due to the small size and light weight of the components, the board should not be turned over unless tack soldered, as they may fall out. The assembly process involves laying the board flat, inserting components with leads flush against the table for a clean back side, and tack soldering all small components before completing the soldering on the reverse side. There have been substitutions of parts throughout the circuit due to availability, which generally enhance circuit reliability. The most critical test to perform is the Ohmmeter test, as the board layout minimizes the risk of shorts between traces, directing any potential shorts to ground. Shorts can arise from solder bridges or manufacturing errors. The Ohmmeter test is straightforward: set the meter to 20K Ohms with the negative terminal connected to the ground plane, using the positive lead to check all circuit pins for shorts. A higher resistance reading is generally acceptable as it may indicate the forward voltage drop of circuit junctions. The installation of Q6, a KSC2330YBU or 2SD667-D NPN transistor, must be performed with care, noting that a BC337 or 2N3904 can be used for 24V applications, albeit with reversed Collector and Base leads. The C2 47uF 50V electrolytic capacitor must be installed with attention to polarity, as indicated by the stripe. While the diagram originally specified 1uF, this capacitor is non-critical and can be substituted with a 22uF capacitor rated for 16V or higher. The same applies to C1.

The LED3X series Tracker PC board is designed for efficient assembly and reliability. The use of through-hole components simplifies the assembly process, allowing for easier handling and soldering. To maximize the integrity of the circuit, it is essential to follow a systematic assembly procedure. This includes ensuring that components are inserted correctly and that the soldering process is conducted in a way that mitigates the risk of damage from heat or static discharge.

The board design incorporates features that facilitate easier troubleshooting and maintenance. The clear labeling of component positions and the inclusion of test points allows for efficient verification of circuit functionality. The use of a grounded workbench and wrist straps is paramount in preventing static discharge, which can lead to component failure.

The emphasis on the Ohmmeter test highlights the importance of verifying circuit integrity before powering the device. This proactive approach to testing ensures that any issues are addressed prior to operation, reducing the risk of component damage during initial use.

Furthermore, the outlined substitutions of parts emphasize adaptability in design, allowing for enhancements in reliability without compromising performance. The flexibility in component values, particularly for the capacitors, provides options for optimization based on available resources while maintaining circuit functionality.

In summary, the LED3X series Tracker PC board represents a well-thought-out design that balances ease of assembly, reliability, and adaptability, making it suitable for various applications while ensuring robust performance.The above table is useful to determine the capabilities of the MOSFETs for the various versions. However, the connectors I have used on the LED3X "c" series is not rated for such high currents on a continuous basis. The connector is technically rated for 7 amps continuous. I find that 10 amps is not to excessive if done intermittently and much hig her currents if the the pulses are short. An experiment I have done was to drive a 12V automotive door window motor. This motor draws about 4 amps at 13. 8V. I raised the voltage to 44V with a pulse width of about 1 second out of a cycle time of 18 seconds. The peak current into the motor is 55 amps @ 1/2 second! Everything remained reasonably cool. Cool huh! The LED3X series Tracker PC boards uses through hole parts. These components are easier to assemble than the surface mount parts on the previous LED3 tracker. The assembly should be done in the specific order outlined to minimize the risk of damage to the circuits in case there are solder shorts or misplaced components. The components in this circuit are susceptible to damage through static discharges. Use normal static discharge prevention techniques such as a grounded workbench, soldering iron, and personal grounding wrist straps.

Also the large mounting hole is connected to the negative power terminal and should be the first point touched when handling the circuit until the connector is installed which can then be the first thing touched. When I say to "Tack Solder" this means to solder one lead of a component on the top side of the board.

I have arranged all the components so one easily accusable lead is always on the end closest to the mounting hole. The components are small and light and one can`t turn the board over unless tack soldered because they will fall out.

Lay the board flat on a table and insert the components so the leads are flush with the table. This make for a clean flat back side. I assemble and tack solder all small components on the top side before turning over to complete the soldering. Also! There have been some substitutions of parts throughout the circuit. These were done mainly due to parts availability. OK, to be honest, I got some good deals on parts at ebay. I will comment about substitutions throughout the assembly instructions. These substitutions generally improve the circuit reliability. The most important test to perform is the Ohmmeter test. This board is laid out in such a way that almost all circuit traces can`t short out to each other, rather, these shorts will be to ground.

Shorts can be caused by a variety of things. The most common is a solder bridge but shorts could come from the PC board manufacturer also. The Ohmmeter test is easy to do. Just set the Ohmmeter to something like 20K Ohms with the - terminal connected to the ground plane. The + lead then tests all the circuit pins looking for zero ohms or shorts. Don`t worry if a higher value is read as this is most likely just the forward drop of the circuit junctions. You can prove this by changing the Ohmmeter scale. If it is a junction the resistance value read will change. If it is a true resistance the value will be the same. Step 12. Install Q6 KSC2330YBU or 2SD667-D NPN Transistor and solder. A BC337 or 2N3904 can be used for 24V operation. Note!, the different package orientations. The BC337 or 2N3904 needs to be installed with the Collector and Base leads reversed. ("c3 revision" has the leads correct for the KSC2330YBU and 2SD667-D. ) C2 47uF 50V Electrolytic Capacitor. Observe the polarity. The stripe is Minus. Was 1uF in the diagram. (Actually this capacitor is quite non critical and may be 22uF and with other voltages, 16V or higher.

) C1 47uF 50V Electrolytic Capacitor. Observe the polarity. The stripe is Minus. Was 1uF in the diagram. (Actually this capacitor is quite non critical and may be 22uF and with other voltages, 16V or higher. ) Vin volts on CONN1 pi 🔗 External reference

The LED3X series Tracker PC board is designed for efficient assembly and reliability. The use of through-hole components simplifies the assembly process, allowing for easier handling and soldering. To maximize the integrity of the circuit, it is essential to follow a systematic assembly procedure. This includes ensuring that components are inserted correctly and that the soldering process is conducted in a way that mitigates the risk of damage from heat or static discharge.

The board design incorporates features that facilitate easier troubleshooting and maintenance. The clear labeling of component positions and the inclusion of test points allows for efficient verification of circuit functionality. The use of a grounded workbench and wrist straps is paramount in preventing static discharge, which can lead to component failure.

The emphasis on the Ohmmeter test highlights the importance of verifying circuit integrity before powering the device. This proactive approach to testing ensures that any issues are addressed prior to operation, reducing the risk of component damage during initial use.

Furthermore, the outlined substitutions of parts emphasize adaptability in design, allowing for enhancements in reliability without compromising performance. The flexibility in component values, particularly for the capacitors, provides options for optimization based on available resources while maintaining circuit functionality.

In summary, the LED3X series Tracker PC board represents a well-thought-out design that balances ease of assembly, reliability, and adaptability, making it suitable for various applications while ensuring robust performance.The above table is useful to determine the capabilities of the MOSFETs for the various versions. However, the connectors I have used on the LED3X "c" series is not rated for such high currents on a continuous basis. The connector is technically rated for 7 amps continuous. I find that 10 amps is not to excessive if done intermittently and much hig her currents if the the pulses are short. An experiment I have done was to drive a 12V automotive door window motor. This motor draws about 4 amps at 13. 8V. I raised the voltage to 44V with a pulse width of about 1 second out of a cycle time of 18 seconds. The peak current into the motor is 55 amps @ 1/2 second! Everything remained reasonably cool. Cool huh! The LED3X series Tracker PC boards uses through hole parts. These components are easier to assemble than the surface mount parts on the previous LED3 tracker. The assembly should be done in the specific order outlined to minimize the risk of damage to the circuits in case there are solder shorts or misplaced components. The components in this circuit are susceptible to damage through static discharges. Use normal static discharge prevention techniques such as a grounded workbench, soldering iron, and personal grounding wrist straps.

Also the large mounting hole is connected to the negative power terminal and should be the first point touched when handling the circuit until the connector is installed which can then be the first thing touched. When I say to "Tack Solder" this means to solder one lead of a component on the top side of the board.

I have arranged all the components so one easily accusable lead is always on the end closest to the mounting hole. The components are small and light and one can`t turn the board over unless tack soldered because they will fall out.

Lay the board flat on a table and insert the components so the leads are flush with the table. This make for a clean flat back side. I assemble and tack solder all small components on the top side before turning over to complete the soldering. Also! There have been some substitutions of parts throughout the circuit. These were done mainly due to parts availability. OK, to be honest, I got some good deals on parts at ebay. I will comment about substitutions throughout the assembly instructions. These substitutions generally improve the circuit reliability. The most important test to perform is the Ohmmeter test. This board is laid out in such a way that almost all circuit traces can`t short out to each other, rather, these shorts will be to ground.

Shorts can be caused by a variety of things. The most common is a solder bridge but shorts could come from the PC board manufacturer also. The Ohmmeter test is easy to do. Just set the Ohmmeter to something like 20K Ohms with the - terminal connected to the ground plane. The + lead then tests all the circuit pins looking for zero ohms or shorts. Don`t worry if a higher value is read as this is most likely just the forward drop of the circuit junctions. You can prove this by changing the Ohmmeter scale. If it is a junction the resistance value read will change. If it is a true resistance the value will be the same. Step 12. Install Q6 KSC2330YBU or 2SD667-D NPN Transistor and solder. A BC337 or 2N3904 can be used for 24V operation. Note!, the different package orientations. The BC337 or 2N3904 needs to be installed with the Collector and Base leads reversed. ("c3 revision" has the leads correct for the KSC2330YBU and 2SD667-D. ) C2 47uF 50V Electrolytic Capacitor. Observe the polarity. The stripe is Minus. Was 1uF in the diagram. (Actually this capacitor is quite non critical and may be 22uF and with other voltages, 16V or higher.

) C1 47uF 50V Electrolytic Capacitor. Observe the polarity. The stripe is Minus. Was 1uF in the diagram. (Actually this capacitor is quite non critical and may be 22uF and with other voltages, 16V or higher. ) Vin volts on CONN1 pi 🔗 External reference