Long time delay

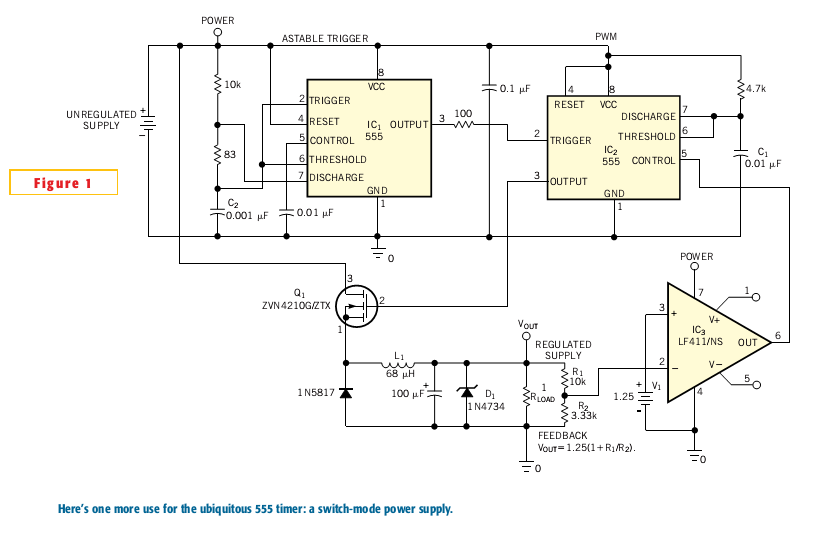

In the 556 timer, the timing is determined by the charging rate of the external capacitor. For prolonged time delays, capacitors with extremely low leakage are necessary, which can be costly. The practicality of the components involved restricts the time between pulses to approximately 10 minutes. To achieve longer time intervals, both sections of a dual timer can be connected in series with a "Divide-by-N" network in between. The first timer section operates in an oscillatory mode with a period of 1/fo. This signal is then fed into a "Divide-by-N" network to produce an output with a period of N/fo, which can subsequently trigger the second half of the 556. The overall time delay is now a function of N and fo.

The 556 timer is a versatile integrated circuit that combines two timing elements, making it suitable for various timing applications. The operation of the 556 timer relies on the charging and discharging of an external capacitor connected to its timing pins. When configured in astable mode, the timer generates a continuous square wave output, with the frequency and duty cycle determined by the resistor and capacitor values.

For applications requiring extended timing intervals, the selection of capacitors becomes critical. High-quality capacitors with minimal leakage currents are essential to ensure accuracy and reliability over long durations. Typically, time delays can be extended by cascading two or more timer sections. The first section operates in an oscillatory mode, generating a pulse train at a frequency of fo. This pulse train is then processed through a "Divide-by-N" network, which effectively reduces the frequency by a factor of N, resulting in a longer period output signal.

The output from the "Divide-by-N" network serves as the trigger for the second section of the 556 timer. This cascading approach allows for substantial increases in timing capabilities, as the total time delay is now a function of both the division factor N and the original frequency fo. By adjusting the resistors and capacitors in the circuit, designers can customize the timing characteristics to meet specific application requirements, thus enhancing the flexibility and functionality of the 556 timer in various electronic projects.In the 556 timer, the timing is a function of the charging rate of the external capacitor. For long time delays, expensive capacitors with extremely low leakage are required. The practicality of the components involved limits the time between pulses to something in the neighborhood of 10 minutes. To achieve longer time periods, both halves of a dual timer may be connected in tandem with a "Divide-by"" network in between the first timer section operates in an oscillatory mode with a period of 1/fo

This signal is then applied to a "Divide-by-N" network to give an output with the period of N/fo. This can then be used to trigger the second half of the 556. The total time delay is now a function of N and fo.

The 556 timer is a versatile integrated circuit that combines two timing elements, making it suitable for various timing applications. The operation of the 556 timer relies on the charging and discharging of an external capacitor connected to its timing pins. When configured in astable mode, the timer generates a continuous square wave output, with the frequency and duty cycle determined by the resistor and capacitor values.

For applications requiring extended timing intervals, the selection of capacitors becomes critical. High-quality capacitors with minimal leakage currents are essential to ensure accuracy and reliability over long durations. Typically, time delays can be extended by cascading two or more timer sections. The first section operates in an oscillatory mode, generating a pulse train at a frequency of fo. This pulse train is then processed through a "Divide-by-N" network, which effectively reduces the frequency by a factor of N, resulting in a longer period output signal.

The output from the "Divide-by-N" network serves as the trigger for the second section of the 556 timer. This cascading approach allows for substantial increases in timing capabilities, as the total time delay is now a function of both the division factor N and the original frequency fo. By adjusting the resistors and capacitors in the circuit, designers can customize the timing characteristics to meet specific application requirements, thus enhancing the flexibility and functionality of the 556 timer in various electronic projects.In the 556 timer, the timing is a function of the charging rate of the external capacitor. For long time delays, expensive capacitors with extremely low leakage are required. The practicality of the components involved limits the time between pulses to something in the neighborhood of 10 minutes. To achieve longer time periods, both halves of a dual timer may be connected in tandem with a "Divide-by"" network in between the first timer section operates in an oscillatory mode with a period of 1/fo

This signal is then applied to a "Divide-by-N" network to give an output with the period of N/fo. This can then be used to trigger the second half of the 556. The total time delay is now a function of N and fo.