low fuel light circuit

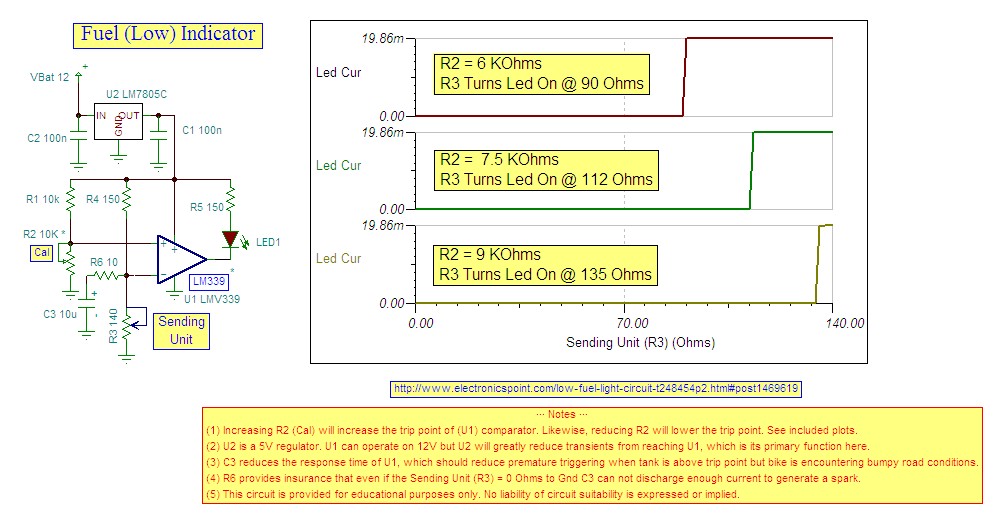

Research indicates that the sender will register a resistance of 100 ohms when the fuel tank is empty, making a trigger reading of 80 ohms optimal.

The fuel gauge sender is a critical component in monitoring the fuel level within a tank. In this scenario, the sender operates on a variable resistance principle, where the resistance value changes based on the fuel level. When the tank is devoid of fuel, the sender outputs a resistance of 100 ohms. This value serves as a reference point for the fuel gauge system.

To ensure accurate fuel level readings, a trigger point is established at 80 ohms. This threshold indicates a level of fuel that is low but not completely empty, allowing for timely alerts to the driver regarding the need for refueling. The choice of 80 ohms as a trigger reading is strategic; it provides a buffer that prevents the risk of running out of fuel entirely while still allowing for a practical range of operation.

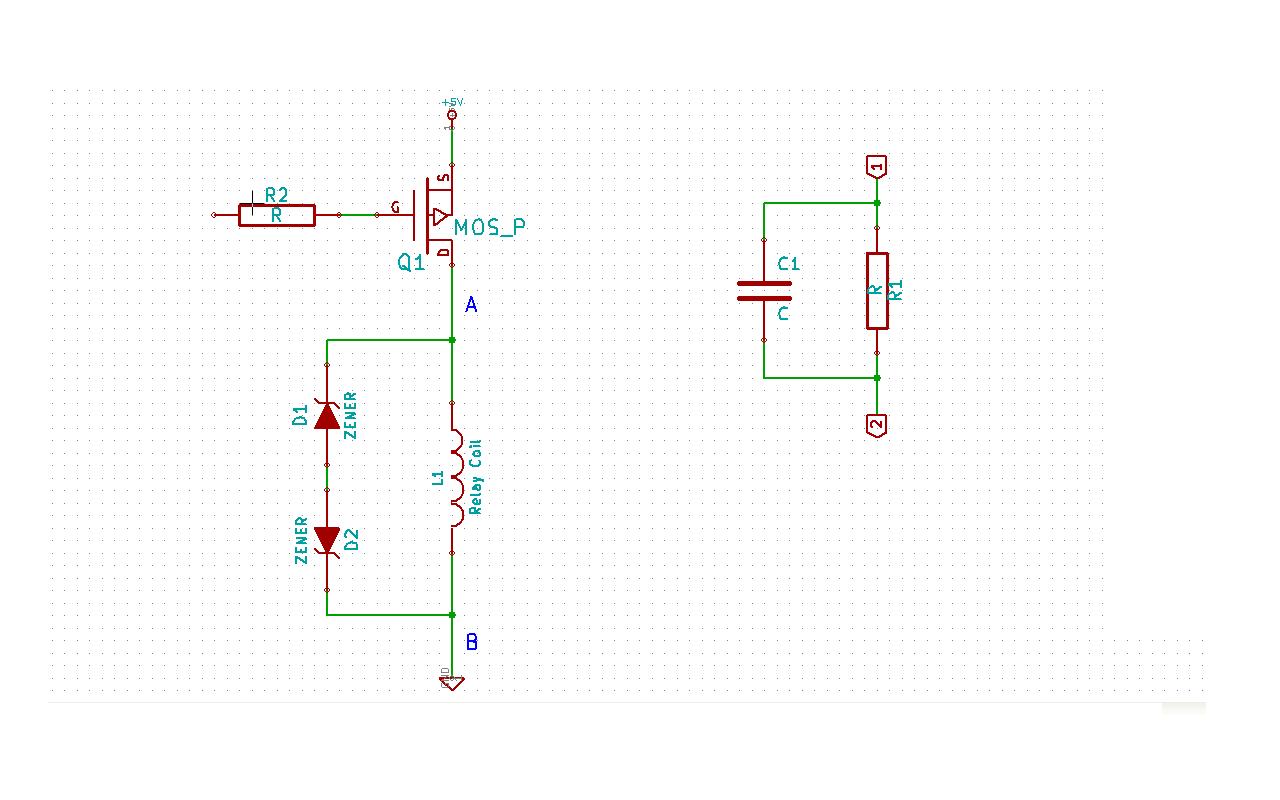

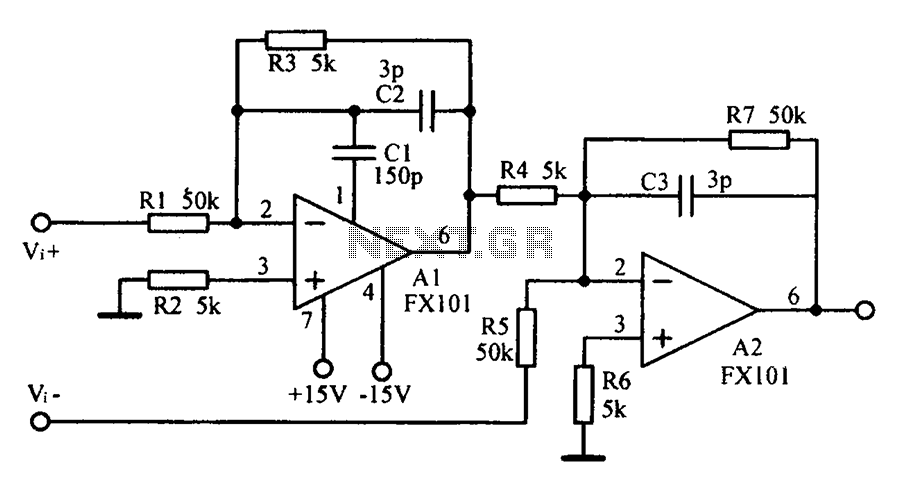

In a typical schematic, this sender would be connected to a fuel gauge via a wire, often referred to as a sender wire. The gauge itself would interpret the resistance from the sender and convert it into a visual representation of the fuel level, usually through a needle on a dial or a digital readout. The circuit may also include a microcontroller that processes the resistance values and triggers an alarm or warning light when the resistance drops to the 80-ohm threshold, indicating the need for refueling.

Additional components may include resistors for calibration, capacitors for noise filtering, and possibly a voltage regulator to ensure stable operation of the gauge and sender circuit. Proper grounding and shielding techniques should be applied to minimize interference from other electrical systems within the vehicle, ensuring that the fuel level readings remain accurate and reliable under various operating conditions.I`ve done some research and found that sender will read 100 ohms when the fuel tank is empty, so a trigger reading of 80 ohms would be ideal.. 🔗 External reference

The fuel gauge sender is a critical component in monitoring the fuel level within a tank. In this scenario, the sender operates on a variable resistance principle, where the resistance value changes based on the fuel level. When the tank is devoid of fuel, the sender outputs a resistance of 100 ohms. This value serves as a reference point for the fuel gauge system.

To ensure accurate fuel level readings, a trigger point is established at 80 ohms. This threshold indicates a level of fuel that is low but not completely empty, allowing for timely alerts to the driver regarding the need for refueling. The choice of 80 ohms as a trigger reading is strategic; it provides a buffer that prevents the risk of running out of fuel entirely while still allowing for a practical range of operation.

In a typical schematic, this sender would be connected to a fuel gauge via a wire, often referred to as a sender wire. The gauge itself would interpret the resistance from the sender and convert it into a visual representation of the fuel level, usually through a needle on a dial or a digital readout. The circuit may also include a microcontroller that processes the resistance values and triggers an alarm or warning light when the resistance drops to the 80-ohm threshold, indicating the need for refueling.

Additional components may include resistors for calibration, capacitors for noise filtering, and possibly a voltage regulator to ensure stable operation of the gauge and sender circuit. Proper grounding and shielding techniques should be applied to minimize interference from other electrical systems within the vehicle, ensuring that the fuel level readings remain accurate and reliable under various operating conditions.I`ve done some research and found that sender will read 100 ohms when the fuel tank is empty, so a trigger reading of 80 ohms would be ideal.. 🔗 External reference