measurement Measuring large differential voltage

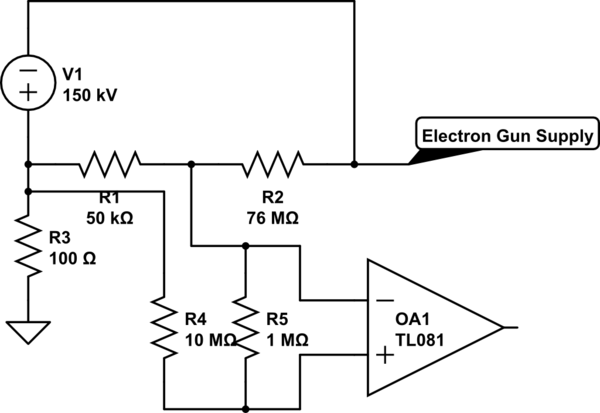

A high voltage power supply is designed for an electron beam system. The voltage regulator utilizes an outdated analog system that operates through a comparator and a reference signal from a potentiometer (POT). The challenge involves the feedback voltage from the high voltage tank, which exceeds 124 volts DC and is floating with respect to ground. The feedback signal is derived from a 50k resistor that is part of a larger resistance network within the tank. This network also connects to an analog 0-1mA meter functioning as a kV meter, so altering the resistance is not an option. The objective is to replace the analog controller with a microcontroller (ATmega) to transition from closed-loop analog control to digital control without disturbing the resistance network inside the tank. An overly simplified schematic of the power supply illustrates that R1 is the feedback resistor, with two wires extending from each terminal to the voltage regulator. R3 represents beam current measurement and overload protection (which is part of a different circuit). The ground is defined as chassis/earth ground. R2 signifies the multiple resistors inside the tank connected to the negative side of the power supply. R4 and R5 are intended as a voltage divider leading to a differential amplifier (the TL801 part number is to be disregarded). The plan is to implement a high impedance divider using 11 megohms of resistance, then feed the scaled-down signal into a unity gain differential amplifier or a high impedance instrumentation amplifier. This amplifier would be powered by an isolating DC-DC power supply, and the signal would be isolated via an isolation amplifier (TI ISO124). Subsequently, the signal can be further scaled using a potentiometer to the microcontroller's ADC.

The high voltage power supply system is critical for the operation of the electron beam apparatus, and meticulous attention to the design is essential to ensure safety and functionality. The existing analog voltage regulation system, while functional, presents limitations in terms of precision and adaptability. The proposed transition to a microcontroller-based control system aims to enhance the performance and reliability of the voltage regulation process.

The feedback mechanism is a crucial aspect of maintaining the desired output voltage. The 50k feedback resistor (R1) plays a pivotal role in this system, as it provides a reference signal to the voltage regulator. Care must be taken to maintain the integrity of the existing resistance network to avoid introducing errors into the voltage measurement process. This network's connection to the analog kV meter necessitates a non-intrusive approach to the redesign.

Incorporating a high impedance voltage divider using 11 megohms ensures that the feedback signal remains accurate while preventing any significant loading effects on the feedback loop. The choice of a unity gain differential amplifier or a high impedance instrumentation amplifier is appropriate, as it allows for precise signal conditioning without introducing additional noise or distortion. The use of an isolating DC-DC power supply is critical in maintaining safety and preventing ground loops, especially when dealing with high voltage systems.

The implementation of the TI ISO124 isolation amplifier is a strategic choice to safeguard the microcontroller from high voltage levels while ensuring that the feedback signal can be accurately processed. The subsequent scaling of the signal through a potentiometer before it reaches the microcontroller's ADC will allow for fine-tuning of the measurement and control process, thereby enhancing the overall functionality of the system.

This design approach not only modernizes the control system but also maintains the integrity of the existing high voltage power supply architecture, ensuring that the electron beam system operates safely and effectively.A high voltage power supply for an electron beam system. The voltage regulator is an old analog system that works via a simple comparator and reference signal from a POT. My problem is the feedback voltage from the high voltage tank (tank meaning large steel oil filled tank with all HV components inside) is upward of 124 volts DC and is floating in respect to ground.

The feedback signal comes from a 50k resistor which is part of a large resistance network inside the tank. Part of that network also runs to an analog 0-1mA meter that is a kV meter so I don`t want to mess with the resistance. I am trying to replace the analog controller with a microcontroller (ATmega) to replace the closed loop analog control with digital control.

I don`t want to mess with the resistance network inside the tank so this has to piggyback existing system and not unbalance the resistance. Below is an overly simplified schematic of the power supply. As you can see R1 is the feedback resistor, two wires are taken from each of its terminals and run to the voltage regulator.

R3 represents beam current measurement and overload protection (different circuit). The ground is chassis/earth ground. R2 represents the numerous resistors inside the tank from the negative side of the power supply. R4 and R5 is my planned divider to a difference amp (ignore the TL801 part number). My idea is to use a high impedance divider using 11 megs of resistance and then feeding that scaled down signal into a unity gain difference amplifier or high impedance instrumentation amplifier. The amplifier would be powered from an isolating DC-DC power supply and the signal isolated via an isolation amplifier ( TI ISO124 ).

From there I can scale it further using a POT to the uC ADC. Any thoughts 🔗 External reference

The high voltage power supply system is critical for the operation of the electron beam apparatus, and meticulous attention to the design is essential to ensure safety and functionality. The existing analog voltage regulation system, while functional, presents limitations in terms of precision and adaptability. The proposed transition to a microcontroller-based control system aims to enhance the performance and reliability of the voltage regulation process.

The feedback mechanism is a crucial aspect of maintaining the desired output voltage. The 50k feedback resistor (R1) plays a pivotal role in this system, as it provides a reference signal to the voltage regulator. Care must be taken to maintain the integrity of the existing resistance network to avoid introducing errors into the voltage measurement process. This network's connection to the analog kV meter necessitates a non-intrusive approach to the redesign.

Incorporating a high impedance voltage divider using 11 megohms ensures that the feedback signal remains accurate while preventing any significant loading effects on the feedback loop. The choice of a unity gain differential amplifier or a high impedance instrumentation amplifier is appropriate, as it allows for precise signal conditioning without introducing additional noise or distortion. The use of an isolating DC-DC power supply is critical in maintaining safety and preventing ground loops, especially when dealing with high voltage systems.

The implementation of the TI ISO124 isolation amplifier is a strategic choice to safeguard the microcontroller from high voltage levels while ensuring that the feedback signal can be accurately processed. The subsequent scaling of the signal through a potentiometer before it reaches the microcontroller's ADC will allow for fine-tuning of the measurement and control process, thereby enhancing the overall functionality of the system.

This design approach not only modernizes the control system but also maintains the integrity of the existing high voltage power supply architecture, ensuring that the electron beam system operates safely and effectively.A high voltage power supply for an electron beam system. The voltage regulator is an old analog system that works via a simple comparator and reference signal from a POT. My problem is the feedback voltage from the high voltage tank (tank meaning large steel oil filled tank with all HV components inside) is upward of 124 volts DC and is floating in respect to ground.

The feedback signal comes from a 50k resistor which is part of a large resistance network inside the tank. Part of that network also runs to an analog 0-1mA meter that is a kV meter so I don`t want to mess with the resistance. I am trying to replace the analog controller with a microcontroller (ATmega) to replace the closed loop analog control with digital control.

I don`t want to mess with the resistance network inside the tank so this has to piggyback existing system and not unbalance the resistance. Below is an overly simplified schematic of the power supply. As you can see R1 is the feedback resistor, two wires are taken from each of its terminals and run to the voltage regulator.

R3 represents beam current measurement and overload protection (different circuit). The ground is chassis/earth ground. R2 represents the numerous resistors inside the tank from the negative side of the power supply. R4 and R5 is my planned divider to a difference amp (ignore the TL801 part number). My idea is to use a high impedance divider using 11 megs of resistance and then feeding that scaled down signal into a unity gain difference amplifier or high impedance instrumentation amplifier. The amplifier would be powered from an isolating DC-DC power supply and the signal isolated via an isolation amplifier ( TI ISO124 ).

From there I can scale it further using a POT to the uC ADC. Any thoughts 🔗 External reference