Microcontroller and Motor Driver Circuit Board

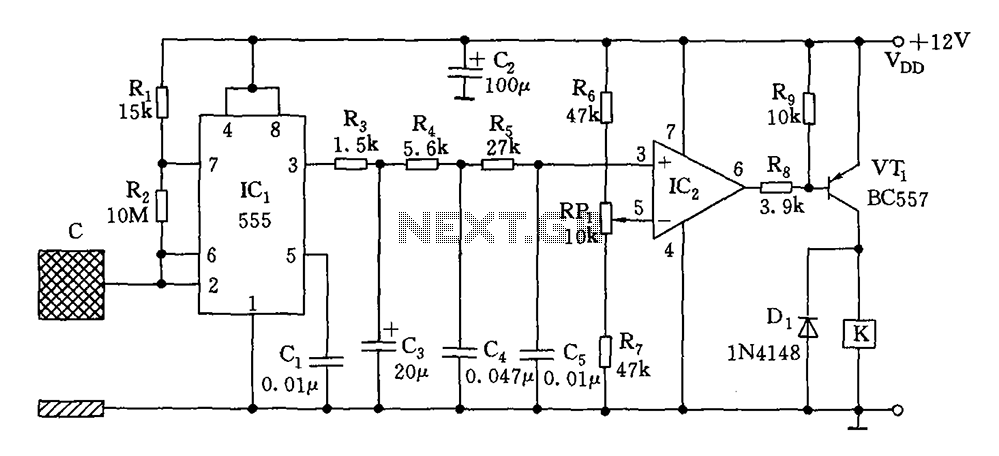

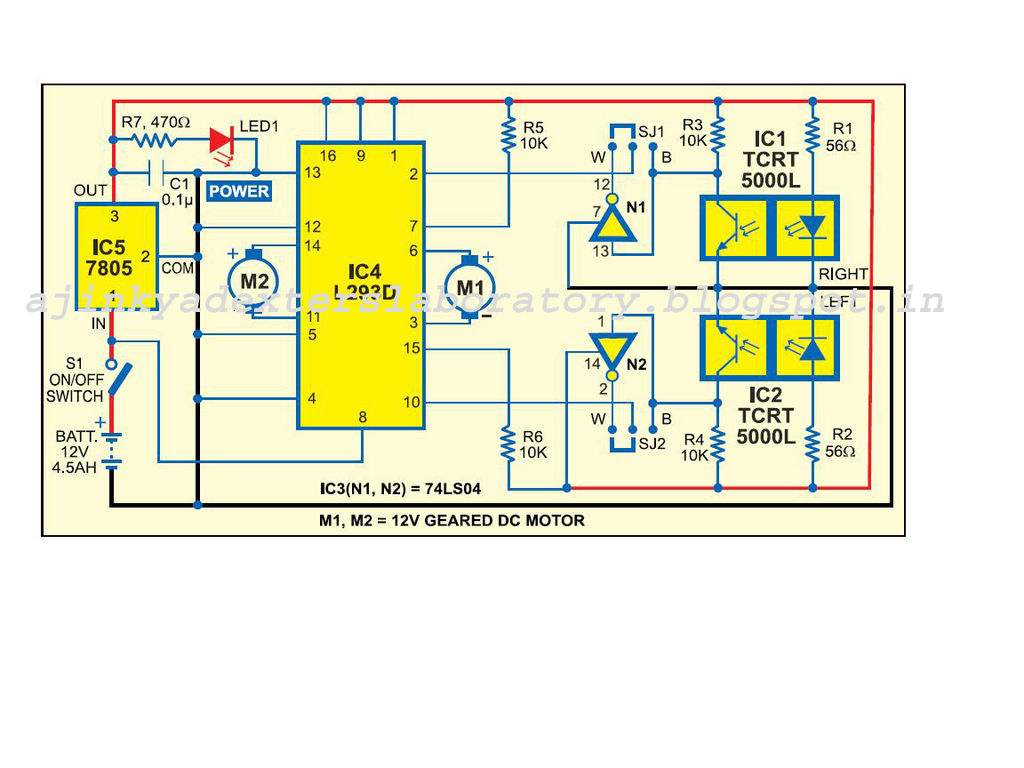

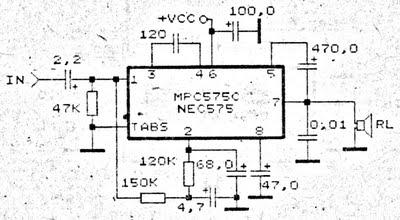

Efforts were made to minimize the number of wire jumpers on this board, but space constraints arose due to the integration of the microcontroller and motor driver on a single board. The design would have been cleaner without the inclusion of the programming header. The L298N serves as a dual motor driver, functioning as a dual H-Bridge motor driver in a compact form factor. The Multiwatt15 through-hole package does not conform to the 0.1-inch spacing standard of most components, making it incompatible with typical perf boards. Affordable breakout boards are available for those who prefer not to engage in etching. The provided view of the board displays all components. Prior to etching, it is advisable to remove all layers except for traces and drill holes.

The circuit design features a compact integration of a microcontroller and an L298N dual motor driver, which allows for efficient control of two DC motors. The L298N is designed to handle the voltage and current requirements of various motors, making it suitable for robotics and automation applications. Its H-Bridge configuration enables bidirectional control of the motors, allowing for forward and reverse operation.

The layout of the board should be carefully considered to optimize space and minimize the number of wire jumpers. While the programming header is essential for firmware updates and debugging, its inclusion can complicate the layout. It is recommended to position the header in a manner that reduces the need for excessive wiring.

Due to the unique pin spacing of the Multiwatt15 package, custom PCB design may be necessary to accommodate this component. Utilizing a PCB design software allows for precise placement of components and traces, ensuring that the board meets the required specifications. For those who prefer a simpler approach, breakout boards compatible with the L298N can be utilized, which can significantly reduce the complexity of the circuit assembly.

Before finalizing the PCB design for etching, it is crucial to ensure that all unnecessary layers are removed, leaving only the copper traces and drill holes visible. This step is vital for achieving a clean etching process, which will result in a more reliable and effective circuit board. Proper preparation and attention to detail in the design phase will contribute to the overall performance and functionality of the integrated microcontroller and motor driver circuit.Tried to limit the number of wire jumpers in this board but things got a little tight since I was combining the microcontroller and motor driver in one board. It would have been a lot cleaner if I would have left the programming header off. The L298N is a dual motor driver that is essentially a dual H-Bridge motor driver in a compact package.

Since the Multiwatt15 through-hole package doesn`t conform to the 0. 1 ³ spacing of most components, it won`t fit directly into standard perf boards. There are inexpensive breakout boards available if you don`t want to worry about etching. This is the view of the board with all of the components. Before printing for etching, you will want to remove the layers except for traces and drill holes. 🔗 External reference

The circuit design features a compact integration of a microcontroller and an L298N dual motor driver, which allows for efficient control of two DC motors. The L298N is designed to handle the voltage and current requirements of various motors, making it suitable for robotics and automation applications. Its H-Bridge configuration enables bidirectional control of the motors, allowing for forward and reverse operation.

The layout of the board should be carefully considered to optimize space and minimize the number of wire jumpers. While the programming header is essential for firmware updates and debugging, its inclusion can complicate the layout. It is recommended to position the header in a manner that reduces the need for excessive wiring.

Due to the unique pin spacing of the Multiwatt15 package, custom PCB design may be necessary to accommodate this component. Utilizing a PCB design software allows for precise placement of components and traces, ensuring that the board meets the required specifications. For those who prefer a simpler approach, breakout boards compatible with the L298N can be utilized, which can significantly reduce the complexity of the circuit assembly.

Before finalizing the PCB design for etching, it is crucial to ensure that all unnecessary layers are removed, leaving only the copper traces and drill holes visible. This step is vital for achieving a clean etching process, which will result in a more reliable and effective circuit board. Proper preparation and attention to detail in the design phase will contribute to the overall performance and functionality of the integrated microcontroller and motor driver circuit.Tried to limit the number of wire jumpers in this board but things got a little tight since I was combining the microcontroller and motor driver in one board. It would have been a lot cleaner if I would have left the programming header off. The L298N is a dual motor driver that is essentially a dual H-Bridge motor driver in a compact package.

Since the Multiwatt15 through-hole package doesn`t conform to the 0. 1 ³ spacing of most components, it won`t fit directly into standard perf boards. There are inexpensive breakout boards available if you don`t want to worry about etching. This is the view of the board with all of the components. Before printing for etching, you will want to remove the layers except for traces and drill holes. 🔗 External reference