mid position valve

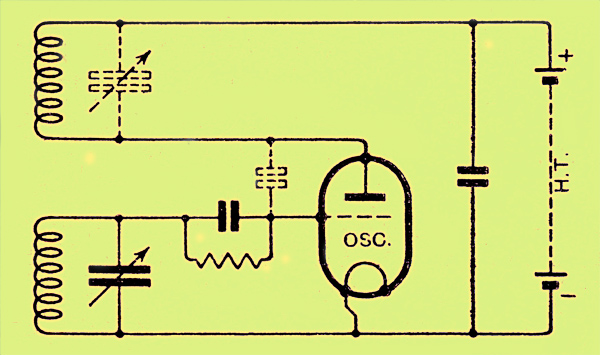

The three-port valve is an innovative engineering solution that operates in one of three positions using a non-reversible AC motor, a spring, a couple of micro-switches, a resistor, and a diode, while also functioning as a relay for the boiler. Its operation can be complex to understand. The spring pulls the valve to open the flow through port B, which is typically connected to the heating coil of the hot water cylinder, while the motor rotates it to open port A, which feeds the radiator circuit. If the motor is continuously powered, it will stall with port A open; however, when powered by DC (produced by the resistor and diode), it can stall in any position. Two micro-switches, SW1 and SW2, are positioned just on either side of the A+B point to define its position. When the valve is at rest, port B is open, and SW1 and SW2 are unactivated. As the valve moves toward position A, SW1 activates just before reaching the A+B point, and SW2 activates just after. The control inputs are white and grey wires, the orange wire is the output to the boiler for port A, and the blue wire is neutral. In the "both off" state for central heating and hot water, the grey wire is live. If the valve is in the A+B or A position, SW1 will be activated, supplying AC to the motor, which will continue to open port A while the orange boiler output remains inactive. This configuration can lead to unnecessary power consumption and motor wear, as the motor consumes 6W. In summer, when heating is not selected, SW1 will rest, and the valve will remain unpowered with port B open. A 270K resistor supplies a small AC current to demagnetize the motor, preventing the return spring from being unable to overcome residual magnetic stiction. In the "water and heating" state, the white wire is energized. If port B is open, the motor will wind until the A+B position is reached, activating SW1, applying DC to the motor via SW2, and causing it to stall. If the valve overshoots or if port A was already open, SW2 will activate, cutting power to the motor and allowing the spring to return the valve to A+B. This movement is dynamic, with the spring pulling the valve back from A open to A+B, causing the motor to gain momentum and overshoot before stopping in the correct position. In the "heating only" state, both white and grey are energized, necessitating a changeover tank thermostat and a "hot water not required" output from the programmer. Regardless of switch positions, AC will be supplied to the motor, which will wind to open port A, and SW2 will connect white to orange, activating the boiler. A common failure mode is motor burnout, leading to the need for replaceable heads. In such cases, the valve will remain in the port B open position with a cold motor. The valve may also become stiff if water infiltrates the O-rings sealing the actuating shaft, resulting in erratic positioning or a hot motor in position B. Applying silicone grease to the operating shaft can resolve this issue, requiring the heating system to be drained, the valve head and cover to be removed, and a circlip to be taken off the shaft. The valve design features a freely rotating rubber ball that pivots on an arm between the two ports.

The three-port valve circuit operates with a combination of mechanical and electronic components to facilitate efficient heating and hot water management within a central heating system. The AC motor is responsible for moving the valve between positions A, B, and A+B, controlled by the micro-switches that act as position sensors. The configuration of the micro-switches is critical, as they provide feedback to ensure the motor is powered correctly based on the valve's position. The resistor and diode work together to convert AC to DC, allowing the motor to hold its position when required while minimizing the risk of overheating and burnout.

In operation, when the system calls for heating, the white wire is energized, activating the motor to open port A. The interaction between the spring and motor is vital for smooth operation, as the spring provides the necessary force to return the valve to its resting position when the motor is deactivated. The valve's design, featuring a rubber ball, allows for minimal friction and wear, enhancing longevity and reliability. Regular maintenance, such as applying silicone grease, is recommended to prevent stiffness and ensure optimal performance.

The circuit's design must also account for safety features, such as the ability to cut power to the motor if it is stalled in an undesirable position, preventing damage and ensuring the system operates safely. Overall, the three-port valve is an essential component of central heating systems, allowing for efficient management of heating and hot water distribution.The three port valve is a masterpiece of clever engineering, in that it manages to move to one of three positions using only a cheap non-reversible AC motor, a spring, a couple of micro-switches, a resistor and a diode, and act as a relay for the boiler into the bargain! However, it has obviously required quite a bit of lateral thinking to conjure up, and its operation is thus not easy to understand. Here`s how it works. The spring pulls the valve to open the flow through port B (traditionally connected to the hot water cylinder`s heating coil), while the motor winds it towards opening port A (feeding the radiator circuit). If the motor is left continuously powered, it will stall in with port A open, but if it is fed with DC (produced with the resistor and the diode), then it will stall in any position.

Two micro-switches, operating just either side of the `A+B` point, are used to define this position. The switches SW1 and SW2 are shown in the valve rest position (port B open). As the valve moves over towards the A position, SW1 changes over just before the A+B point, and SW2 just after. The white and grey wires are the control inputs, the orange is the output to the boiler for port A open, and blue is neutral.

In the central heating and hot water "both off" state, the system wiring results in grey being live. If the valve happens to be in the A+B or A port open position, SW1 will have been operated, the motor will be fed with AC, and the valve will wind to open port A and stay there (although the orange boiler output will not be live). This is a fly in the ointment for this valve configuration: the motor can be left consuming power and wearing out its hot windings unnecessarily (the spec says the valve consumes 6W).

This will not happen in the summer though, when heating is never selected: SW1 will be at rest, and the valve will sit un-energised with port B open. The 270K resistor supplies a small AC current to de-magnetise the motor from the effects of the rectified DC that is used to hold it in the mid-position.

Without this, there is some risk that the return spring will not be able to overcome the residual magnetic stiction to return it to the end position. In the "water and heating" state, white is energised. If the valve has port B open, the motor will wind it until A+B, whereupon SW1 changes over, DC is applied to the motor via SW2, and it will stall.

If it overshoots, or if it port A was open, SW2 will be operated as well, removing all power from the motor, and allowing the spring to pull the valve back to A+B. It is fun to watch this happening: as the spring pulls the valve back from A open to A+B, the motor acquires quite a momentum and overshoots.

It then winds forward a little, and stops in the correct position. In the "heating only" state, both white and grey are energised (hence the need for a changeover tank stat, and a "hot water not required" output from the programmer). Regardless of the position of either switch, AC will be supplied to the motor, and it will wind to open port A.

In addition, SW2 will connect white to orange, switching on the boiler. (The boiler is switched externally to the valve in the other situations. ) As has already been mentioned, a common failure mode is the motor burning out: hence the provision of replaceable heads. In this case, the valve will sit in port B open position and the motor will be cold. The valve can also stiffen up, if water gets in between the two O-rings that seal the actuating shaft.

This will manifest itself as the valve sitting in a random position, or in position B but with a hot motor. Applying silicone grease to the operating shaft can cure this: the heating will need to be drained, the valve head and cover removed, and a cir-clip taken off the shaft.

The actual valve consists of a freely-rotating rubber ball which is swung on an arm between the two ports. For more on central heating valves fo all 🔗 External reference

The three-port valve circuit operates with a combination of mechanical and electronic components to facilitate efficient heating and hot water management within a central heating system. The AC motor is responsible for moving the valve between positions A, B, and A+B, controlled by the micro-switches that act as position sensors. The configuration of the micro-switches is critical, as they provide feedback to ensure the motor is powered correctly based on the valve's position. The resistor and diode work together to convert AC to DC, allowing the motor to hold its position when required while minimizing the risk of overheating and burnout.

In operation, when the system calls for heating, the white wire is energized, activating the motor to open port A. The interaction between the spring and motor is vital for smooth operation, as the spring provides the necessary force to return the valve to its resting position when the motor is deactivated. The valve's design, featuring a rubber ball, allows for minimal friction and wear, enhancing longevity and reliability. Regular maintenance, such as applying silicone grease, is recommended to prevent stiffness and ensure optimal performance.

The circuit's design must also account for safety features, such as the ability to cut power to the motor if it is stalled in an undesirable position, preventing damage and ensuring the system operates safely. Overall, the three-port valve is an essential component of central heating systems, allowing for efficient management of heating and hot water distribution.The three port valve is a masterpiece of clever engineering, in that it manages to move to one of three positions using only a cheap non-reversible AC motor, a spring, a couple of micro-switches, a resistor and a diode, and act as a relay for the boiler into the bargain! However, it has obviously required quite a bit of lateral thinking to conjure up, and its operation is thus not easy to understand. Here`s how it works. The spring pulls the valve to open the flow through port B (traditionally connected to the hot water cylinder`s heating coil), while the motor winds it towards opening port A (feeding the radiator circuit). If the motor is left continuously powered, it will stall in with port A open, but if it is fed with DC (produced with the resistor and the diode), then it will stall in any position.

Two micro-switches, operating just either side of the `A+B` point, are used to define this position. The switches SW1 and SW2 are shown in the valve rest position (port B open). As the valve moves over towards the A position, SW1 changes over just before the A+B point, and SW2 just after. The white and grey wires are the control inputs, the orange is the output to the boiler for port A open, and blue is neutral.

In the central heating and hot water "both off" state, the system wiring results in grey being live. If the valve happens to be in the A+B or A port open position, SW1 will have been operated, the motor will be fed with AC, and the valve will wind to open port A and stay there (although the orange boiler output will not be live). This is a fly in the ointment for this valve configuration: the motor can be left consuming power and wearing out its hot windings unnecessarily (the spec says the valve consumes 6W).

This will not happen in the summer though, when heating is never selected: SW1 will be at rest, and the valve will sit un-energised with port B open. The 270K resistor supplies a small AC current to de-magnetise the motor from the effects of the rectified DC that is used to hold it in the mid-position.

Without this, there is some risk that the return spring will not be able to overcome the residual magnetic stiction to return it to the end position. In the "water and heating" state, white is energised. If the valve has port B open, the motor will wind it until A+B, whereupon SW1 changes over, DC is applied to the motor via SW2, and it will stall.

If it overshoots, or if it port A was open, SW2 will be operated as well, removing all power from the motor, and allowing the spring to pull the valve back to A+B. It is fun to watch this happening: as the spring pulls the valve back from A open to A+B, the motor acquires quite a momentum and overshoots.

It then winds forward a little, and stops in the correct position. In the "heating only" state, both white and grey are energised (hence the need for a changeover tank stat, and a "hot water not required" output from the programmer). Regardless of the position of either switch, AC will be supplied to the motor, and it will wind to open port A.

In addition, SW2 will connect white to orange, switching on the boiler. (The boiler is switched externally to the valve in the other situations. ) As has already been mentioned, a common failure mode is the motor burning out: hence the provision of replaceable heads. In this case, the valve will sit in port B open position and the motor will be cold. The valve can also stiffen up, if water gets in between the two O-rings that seal the actuating shaft.

This will manifest itself as the valve sitting in a random position, or in position B but with a hot motor. Applying silicone grease to the operating shaft can cure this: the heating will need to be drained, the valve head and cover removed, and a cir-clip taken off the shaft.

The actual valve consists of a freely-rotating rubber ball which is swung on an arm between the two ports. For more on central heating valves fo all 🔗 External reference