Motor-tachometer speed control

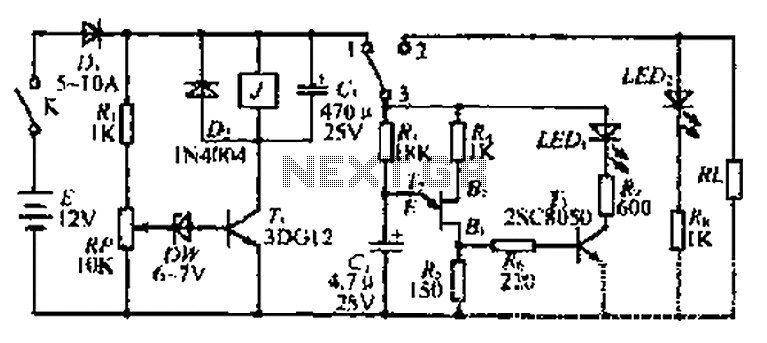

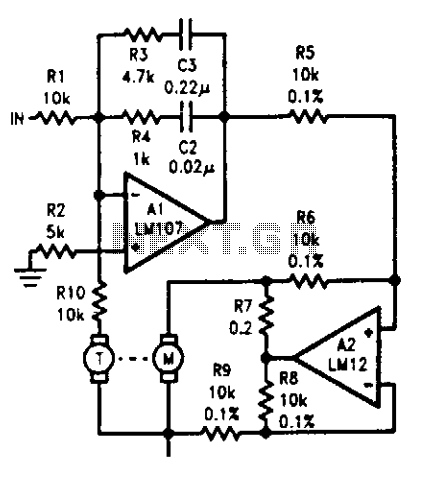

The tachometer, mounted on the same shaft as the DC motor, functions as a generator, producing a DC output voltage that is proportional to the motor's speed. A summing amplifier, labeled as Al, manages its output to ensure that the tachometer voltage is equal to the input voltage but with an opposite polarity. When current is supplied to the motor, the tachometer experiences a 90° phase lag before secondary effects are taken into account. The compensation for Al is engineered to maintain a phase shift of less than 90° across the frequency range where the servo loop reaches unity gain. If the response time is not a critical factor, a power operational amplifier could replace Al to drive the motor directly. Additionally, reducing the break frequencies of the compensation would be necessary. This circuit can also function as a position servo; it requires a voltage that indicates both the direction and magnitude of the motor shaft's displacement from a target position. This error signal is connected to the input, prompting the servo to adjust the output to zero. The tachometer remains essential for generating a phase-correcting rate signal, as the error signal lags the motor drive by 180°.

The described circuit integrates a tachometer with a DC motor to provide feedback on the motor's speed, enabling precise control over its operation. The tachometer generates a DC voltage that reflects the motor's speed, which is essential for closed-loop control in servo systems. The summing amplifier Al plays a crucial role in this feedback mechanism by ensuring that the output voltage from the tachometer is effectively inverted, allowing for proper error correction.

The design of the summing amplifier includes compensation techniques that are vital in maintaining stability within the control loop. By ensuring that the phase shift remains below 90° within the operational frequency range, the system can avoid instability and oscillations that could arise from excessive phase lag. The ability to substitute a power operational amplifier for Al provides flexibility in the design, allowing for direct motor drive when rapid response is less critical.

In the context of position control, the circuit can be adapted to function as a position servo by incorporating a method to measure the displacement of the motor shaft from a predetermined setpoint. This involves generating an error signal that indicates the difference between the actual position and the desired position. The servo system then works to minimize this error, effectively driving the motor to the correct position.

It is important to note that the tachometer's feedback is necessary not only for speed control but also for compensating the phase lag introduced by the error signal. The inherent 180° lag must be countered to ensure that the control system remains responsive and accurate. Therefore, the integration of the tachometer and the summing amplifier is essential for achieving both speed regulation and positional accuracy in servo applications.The tachometer, on the same shaft as the dc motor, is simply a generator. It gives a dc output voltage proportional to the speed of the motor. A summing amplifier, Al, controls its output so that the tachometer voltage equals the input voltage, but of opposite sign. With current drive to the motor, phase lag to the tachometer is 90°, before the second order effects come in.

Compensation on Al is designed to give less than 90° phase shift over the range of frequencies where the servo loop goes through unity gain. Should response time be of less concern, a power op amp could be substituted for Al to drive the motor directly.

Lowering break frequencies of the compensation would, of course, be necessary. The circuit could also be used as a position servo. All that is needed is a voltage indicating the sense and magnitude of the motor shaft displacement from a desired position. This error signal is connected to the input, and the servo works to make it zero. The tachometer is still required to develop a phase-correcting rate signal because the error signal lags the motor drive by 180°.

The described circuit integrates a tachometer with a DC motor to provide feedback on the motor's speed, enabling precise control over its operation. The tachometer generates a DC voltage that reflects the motor's speed, which is essential for closed-loop control in servo systems. The summing amplifier Al plays a crucial role in this feedback mechanism by ensuring that the output voltage from the tachometer is effectively inverted, allowing for proper error correction.

The design of the summing amplifier includes compensation techniques that are vital in maintaining stability within the control loop. By ensuring that the phase shift remains below 90° within the operational frequency range, the system can avoid instability and oscillations that could arise from excessive phase lag. The ability to substitute a power operational amplifier for Al provides flexibility in the design, allowing for direct motor drive when rapid response is less critical.

In the context of position control, the circuit can be adapted to function as a position servo by incorporating a method to measure the displacement of the motor shaft from a predetermined setpoint. This involves generating an error signal that indicates the difference between the actual position and the desired position. The servo system then works to minimize this error, effectively driving the motor to the correct position.

It is important to note that the tachometer's feedback is necessary not only for speed control but also for compensating the phase lag introduced by the error signal. The inherent 180° lag must be countered to ensure that the control system remains responsive and accurate. Therefore, the integration of the tachometer and the summing amplifier is essential for achieving both speed regulation and positional accuracy in servo applications.The tachometer, on the same shaft as the dc motor, is simply a generator. It gives a dc output voltage proportional to the speed of the motor. A summing amplifier, Al, controls its output so that the tachometer voltage equals the input voltage, but of opposite sign. With current drive to the motor, phase lag to the tachometer is 90°, before the second order effects come in.

Compensation on Al is designed to give less than 90° phase shift over the range of frequencies where the servo loop goes through unity gain. Should response time be of less concern, a power op amp could be substituted for Al to drive the motor directly.

Lowering break frequencies of the compensation would, of course, be necessary. The circuit could also be used as a position servo. All that is needed is a voltage indicating the sense and magnitude of the motor shaft displacement from a desired position. This error signal is connected to the input, and the servo works to make it zero. The tachometer is still required to develop a phase-correcting rate signal because the error signal lags the motor drive by 180°.