Mp pulse width control

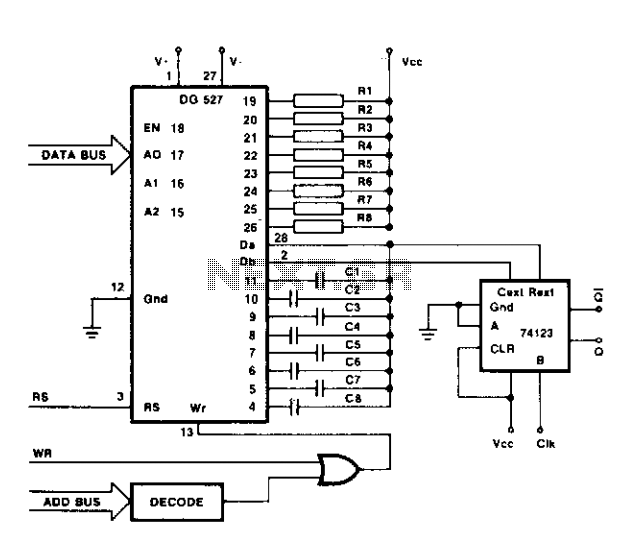

Differential multiplexers are typically employed in process control applications to mitigate errors caused by common mode signals. In this circuit, the dual multiplexing capability of the switch is utilized. This is accomplished by using the multiplexer to select pairs of RC networks, which control the pulse width of the multivibrator. This feature is particularly beneficial in process control applications that require a variable width sample "window" for different control signals.

In electronic circuit design, differential multiplexers offer a significant advantage by enabling the selection of multiple input signals while rejecting common mode noise. This is particularly crucial in environments where signal integrity is paramount, such as industrial process control systems. By leveraging the dual multiplexing capability, the circuit can dynamically adjust the pulse width of a multivibrator, which is essential for generating precise timing signals.

The operation of the differential multiplexer involves selecting pairs of resistors and capacitors (RC networks) that define the charge and discharge times of the multivibrator. By varying the RC time constants, the pulse width can be finely tuned to accommodate different control signals that may require varying sampling intervals. This adaptability is essential in scenarios where control signals fluctuate in frequency or duty cycle, allowing for improved responsiveness and accuracy in process control.

In practical applications, the configuration of the RC networks can be designed to optimize performance based on the specific requirements of the control system. For instance, if a wider sample window is needed for a slower control signal, the corresponding RC pair can be selected to produce a longer pulse width. Conversely, for faster signals, a different RC combination can be chosen to shorten the pulse width, thus ensuring that the system can effectively sample and respond to changes in the control signals.

Overall, the integration of differential multiplexers in process control circuits enhances the system's ability to handle diverse signal conditions while maintaining high fidelity in signal processing. This capability is essential for achieving reliable and efficient operation in complex industrial environments.Differential multiplexers are generally used in process control applications to eliminate errors due to common mode signals. In this circuit however, advantage is taken of the dual multiplexing capability of the switch. This is achieved by using the multiplexer to select pairs of RC networks to control the pulse width of the multivibrator.

This can be a particularly useful feature in process control applications where there is a requirement for a variable width sample "window" for different control signals.

In electronic circuit design, differential multiplexers offer a significant advantage by enabling the selection of multiple input signals while rejecting common mode noise. This is particularly crucial in environments where signal integrity is paramount, such as industrial process control systems. By leveraging the dual multiplexing capability, the circuit can dynamically adjust the pulse width of a multivibrator, which is essential for generating precise timing signals.

The operation of the differential multiplexer involves selecting pairs of resistors and capacitors (RC networks) that define the charge and discharge times of the multivibrator. By varying the RC time constants, the pulse width can be finely tuned to accommodate different control signals that may require varying sampling intervals. This adaptability is essential in scenarios where control signals fluctuate in frequency or duty cycle, allowing for improved responsiveness and accuracy in process control.

In practical applications, the configuration of the RC networks can be designed to optimize performance based on the specific requirements of the control system. For instance, if a wider sample window is needed for a slower control signal, the corresponding RC pair can be selected to produce a longer pulse width. Conversely, for faster signals, a different RC combination can be chosen to shorten the pulse width, thus ensuring that the system can effectively sample and respond to changes in the control signals.

Overall, the integration of differential multiplexers in process control circuits enhances the system's ability to handle diverse signal conditions while maintaining high fidelity in signal processing. This capability is essential for achieving reliable and efficient operation in complex industrial environments.Differential multiplexers are generally used in process control applications to eliminate errors due to common mode signals. In this circuit however, advantage is taken of the dual multiplexing capability of the switch. This is achieved by using the multiplexer to select pairs of RC networks to control the pulse width of the multivibrator.

This can be a particularly useful feature in process control applications where there is a requirement for a variable width sample "window" for different control signals.