One circuit electromagnetic vibration table

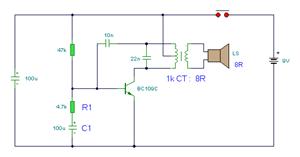

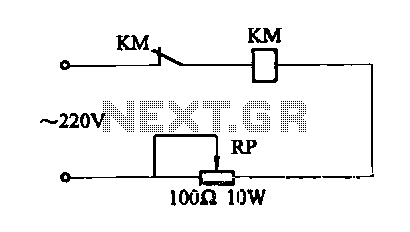

An electromagnetic vibration table or feeder is designed to move small objects along a specific track or cylindrical path through forced vibrations. This device can be custom-built to facilitate the movement of items along a rail tube. The vibration source consists of a non-electrical short ring made of Mu iron. The simplest electric vibrating feeder, as illustrated in Figure 6-38, operates by opening and closing the contacts of an AC contactor, which in turn causes the iron core to vibrate. By adjusting the rheostat (RP), the oscillation can be synchronized to match the natural frequency of the armature's vibration frequency.

The electromagnetic vibration feeder operates on the principle of electromagnetic induction, where an alternating current is passed through a coil to generate a magnetic field. This magnetic field interacts with the iron core, inducing vibrations that facilitate the movement of materials. The design typically includes a base plate, a coil assembly, and a spring mechanism that allows for the adjustment of vibration intensity and frequency.

The feeder's performance can be optimized by selecting the appropriate dimensions of the coil, the type of material used for the core, and the configuration of the track. The rheostat plays a crucial role in fine-tuning the frequency of the vibrations to ensure optimal movement of the objects being fed. This adjustment is vital, as the efficiency of the feeding process is highly dependent on maintaining resonance between the feeder's vibrations and the natural frequency of the objects.

In practical applications, these feeders are widely used in industries such as manufacturing, packaging, and material handling, where precise control of material flow is essential. The ability to customize the feeder's design and operation makes it a versatile solution for various material transport challenges.Electromagnetic vibration table or feeder is to use small objects after a certain track or cylinder by forced vibration, can be self- made line made to move along the rail tube phenomenon or a feeding device. Vibration source is a non-electrical short ring Mu iron. Figure 6-38 is the simplest electric vibrating feeder, use it to remove the short-circuit loop AC contactor contacts open and close the iron core vibration made. Adjust rheostat RP, so consistent and oscillation occurs with the natural frequency of the vibration frequency of the armature.

The electromagnetic vibration feeder operates on the principle of electromagnetic induction, where an alternating current is passed through a coil to generate a magnetic field. This magnetic field interacts with the iron core, inducing vibrations that facilitate the movement of materials. The design typically includes a base plate, a coil assembly, and a spring mechanism that allows for the adjustment of vibration intensity and frequency.

The feeder's performance can be optimized by selecting the appropriate dimensions of the coil, the type of material used for the core, and the configuration of the track. The rheostat plays a crucial role in fine-tuning the frequency of the vibrations to ensure optimal movement of the objects being fed. This adjustment is vital, as the efficiency of the feeding process is highly dependent on maintaining resonance between the feeder's vibrations and the natural frequency of the objects.

In practical applications, these feeders are widely used in industries such as manufacturing, packaging, and material handling, where precise control of material flow is essential. The ability to customize the feeder's design and operation makes it a versatile solution for various material transport challenges.Electromagnetic vibration table or feeder is to use small objects after a certain track or cylinder by forced vibration, can be self- made line made to move along the rail tube phenomenon or a feeding device. Vibration source is a non-electrical short ring Mu iron. Figure 6-38 is the simplest electric vibrating feeder, use it to remove the short-circuit loop AC contactor contacts open and close the iron core vibration made. Adjust rheostat RP, so consistent and oscillation occurs with the natural frequency of the vibration frequency of the armature.