PCB exposure box Based on ATmega8 AVR microcontroller

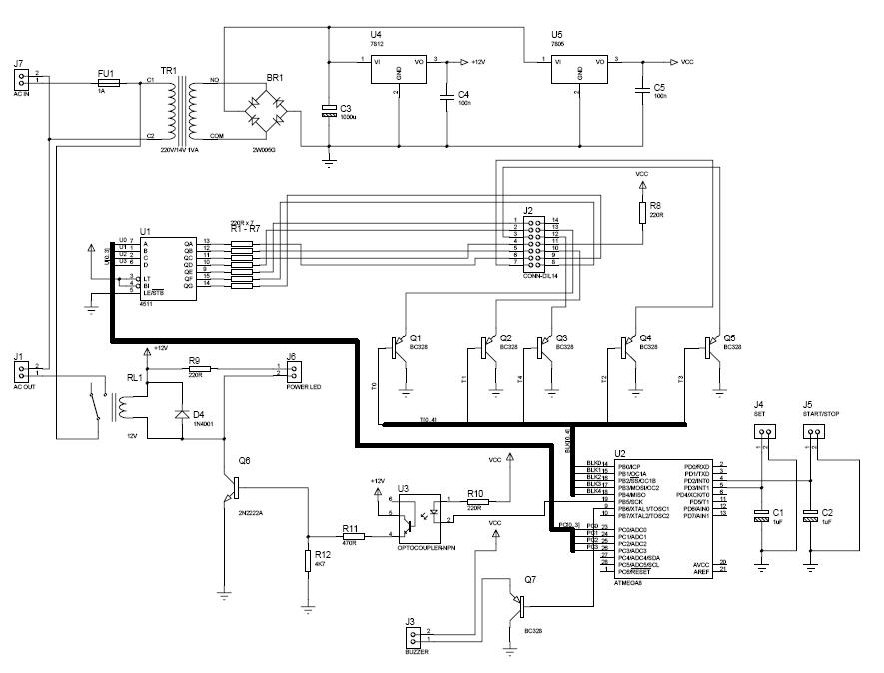

The procedure outlines the construction of a Box, Lamp System, and Countdown System utilizing the AVR Mega8 microcontroller. The system features four blacklight lamps, each rated at 15W, which emit radiation primarily in the UVA spectrum, peaking around 350nm, targeting the photosensitive board's surface above the copper. The lamps are arranged in pairs, connected in series, forming two identical modules. Each module includes its own ballast and can be connected to 220V AC through a relay. The microcontroller manages a user-defined countdown, activating the relay upon reaching zero. The remaining time is displayed on four 7-segment LED displays, with a maximum countdown of 99 minutes and 59 seconds. The countdown is set using two buttons: SET and START/STOP. A brief press on the SET button increments the current digit, while a prolonged press cycles through the time units. Pressing the START/STOP button once accepts the countdown, and pressing it again starts the countdown, connecting the lamp system to 220V AC via the relay. If pressed before the countdown expires, the lamp system deactivates. Upon reaching zero, the lamp system shuts off, and a 3-second beep sounds. The timer retains the last used countdown as the default for subsequent power-ups. The box dimensions are approximately 50x30x60 cm³, with additional space for the countdown board and two ballasts, allowing a height of 5-8 cm for this compartment. The shelf includes four starter bases on one side and the four lamps with their G13 bases on the other. The design references Papanikolaou's Darkroom Timer project. The lamps, such as the F15W/T8/BL from Sylvania and Actinic BL from Philips, are suitable for photochemical processes and insect control. Each module connects in parallel, initially allowing AC current to flow through the starters and ballast. Eventually, one starter opens, halting current flow, which causes the ballast inductor to generate a high voltage, necessary for lamp ignition. Post-ignition, the voltage stabilizes around 50-60V, as specified in the manuals. The G13 lamp holders are installed on the shelf, with drilled holes for wire connections. The software was developed in C using winAVR and avr-gcc with avrStudio, and code simulation was conducted in ProteusVSM. The hex code was then programmed into the chip using the STK500 programmer.

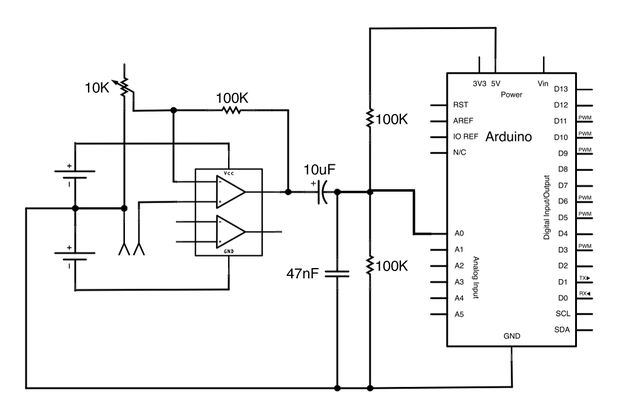

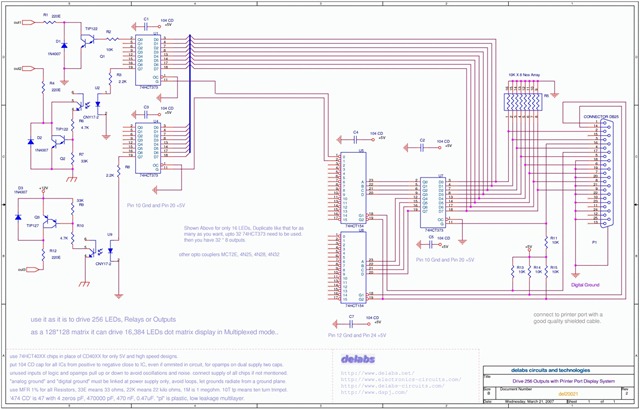

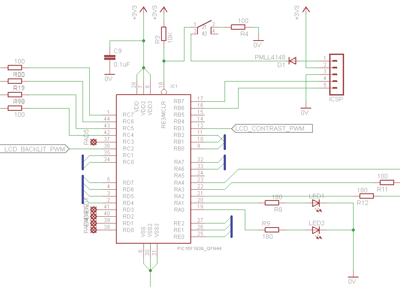

The system architecture comprises a microcontroller-based control unit interfacing with a relay module, which manages the AC power supply to the lamp system. The relay acts as a switch controlled by the microcontroller, allowing for safe operation of the high-voltage components. The microcontroller's GPIO pins are configured to read the input from the SET and START/STOP buttons and to drive the 7-segment LED displays, providing a user-friendly interface for countdown management.

The countdown logic is implemented in the firmware, ensuring that the user can easily set the desired time. The system employs debouncing techniques for button presses to avoid erroneous readings. When the countdown is initiated, the microcontroller continuously monitors the timer and updates the display until it reaches zero, at which point it deactivates the relay, cutting power to the lamp system, and triggers an audible alert.

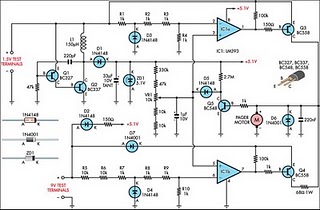

The lamp modules utilize a combination of starters and ballasts to ensure proper ignition and operation of the fluorescent lamps. The design incorporates safety features, including fuses and isolation measures to protect the user from high voltages generated during the lamp ignition process. The layout of the components within the box is optimized for thermal management and accessibility, ensuring that the system operates efficiently and safely over extended periods.

In summary, this project integrates electronic design principles with practical applications, enabling effective control of a lamp system for photochemical and pest control purposes. The use of microcontroller technology enhances functionality, allowing for precise countdown management and user interaction while maintaining safety and reliability.I describe the procedure I followed to build the Box, the Lamp System and the Countdown System which is based on the AVR mega8 microcontroller. Four blacklight lamps, 15W each, emit radiation at the region of UVA, with a peak around 350nm where the thin surface above the copper of the photosensitive board, is.

sensitive. The lamps are taken by two and are connected in series thus shaping two similar modules. Each module has its own ballast and can be connected to 220V AC via a relay. A microcontroller counts a user defined countdown and upon reaching zero activates a relay. The time remaining is displayed on four 7-segment led displays. The maximum countdown is 99 minutes and 59 secs. The desired countdown is entered using only two buttons, SET and START/STOP. Short term push of the SET button will increase the current digit while prolonged push will change the digit from secondss to decades of seconds, to minutes and so on. Pushing once the START/STOP button, will make the MCU accept the desired countdown. Pushing the START/STOP button one more time, will start the countdown and connect the lamp system to 220V AC, via the relay.

If START/STOP button is pushed again before countdown reaches zero, the lamp system will be deactivated. When the countdown reaches zero the lamp system is deactivated and a 3 seconds beep is sounded. The timer remembers the last used countdown and uses it as default every time the system is switched on.

You are gonna need a wooden box with dimensions aproximately 50x30x60 cm3. The box must have an extra room for hosting the countdown board and the two ballasts. The height of that room, that is the distance between the bottom of the box and the shelf, can be 5-8 cm. On the one side of the shelf will be installed the four starter bases and on the other side the four lamps along with their G13 bases.

Here there is a very detailed description on how to build your own box, upon which I relied to decide the dimensions of my box. However the final design I used is the same as Papanikolaou`s box in his Darkroom Timer project. Many thanks to both of them! 4 x 15W Black Light UVA fluorescent lamps with a peak of radiation at ~350nm. Those lamps are suitable for photochemical procedures and can usually be used in insect killing. Examples are F15W/T8/BL from Syllvania and Actinic BL from Phillips There are twoidentical modules connected in parallel.

In each module, initially, the AC current flows through the two starters and the ballast. After a while one of the starters goes open-circuited and the current in the circuit is halted. This brings the ballast inductor in an extremely uncomfortable situation and it reacts violently developing a great voltage across its terminals. The value of the voltage can be as large as some kV and that is exactly what the fluorescent lamps need in order to be turned on.

After that transition effect the voltage accross each lamp gets stabillized around the 50~60V which is the lamp`s operation voltage shown in the manuals. Second, on the other side of the shelf, I screwed the eight G13 lamp holders, having first, drilled the holes needed by the wires to join the lamp bases with the starter bases.

As for the Software part I wrote the code in C using the winAVR and avr-gcc plugin along with avrStudio. Using ProteusVSM I tested the code in simulation environment which saved me a lot of effort and time.

Then I downloaded the hex code to the chip with the STK500. I strongly recommend 🔗 External reference

The system architecture comprises a microcontroller-based control unit interfacing with a relay module, which manages the AC power supply to the lamp system. The relay acts as a switch controlled by the microcontroller, allowing for safe operation of the high-voltage components. The microcontroller's GPIO pins are configured to read the input from the SET and START/STOP buttons and to drive the 7-segment LED displays, providing a user-friendly interface for countdown management.

The countdown logic is implemented in the firmware, ensuring that the user can easily set the desired time. The system employs debouncing techniques for button presses to avoid erroneous readings. When the countdown is initiated, the microcontroller continuously monitors the timer and updates the display until it reaches zero, at which point it deactivates the relay, cutting power to the lamp system, and triggers an audible alert.

The lamp modules utilize a combination of starters and ballasts to ensure proper ignition and operation of the fluorescent lamps. The design incorporates safety features, including fuses and isolation measures to protect the user from high voltages generated during the lamp ignition process. The layout of the components within the box is optimized for thermal management and accessibility, ensuring that the system operates efficiently and safely over extended periods.

In summary, this project integrates electronic design principles with practical applications, enabling effective control of a lamp system for photochemical and pest control purposes. The use of microcontroller technology enhances functionality, allowing for precise countdown management and user interaction while maintaining safety and reliability.I describe the procedure I followed to build the Box, the Lamp System and the Countdown System which is based on the AVR mega8 microcontroller. Four blacklight lamps, 15W each, emit radiation at the region of UVA, with a peak around 350nm where the thin surface above the copper of the photosensitive board, is.

sensitive. The lamps are taken by two and are connected in series thus shaping two similar modules. Each module has its own ballast and can be connected to 220V AC via a relay. A microcontroller counts a user defined countdown and upon reaching zero activates a relay. The time remaining is displayed on four 7-segment led displays. The maximum countdown is 99 minutes and 59 secs. The desired countdown is entered using only two buttons, SET and START/STOP. Short term push of the SET button will increase the current digit while prolonged push will change the digit from secondss to decades of seconds, to minutes and so on. Pushing once the START/STOP button, will make the MCU accept the desired countdown. Pushing the START/STOP button one more time, will start the countdown and connect the lamp system to 220V AC, via the relay.

If START/STOP button is pushed again before countdown reaches zero, the lamp system will be deactivated. When the countdown reaches zero the lamp system is deactivated and a 3 seconds beep is sounded. The timer remembers the last used countdown and uses it as default every time the system is switched on.

You are gonna need a wooden box with dimensions aproximately 50x30x60 cm3. The box must have an extra room for hosting the countdown board and the two ballasts. The height of that room, that is the distance between the bottom of the box and the shelf, can be 5-8 cm. On the one side of the shelf will be installed the four starter bases and on the other side the four lamps along with their G13 bases.

Here there is a very detailed description on how to build your own box, upon which I relied to decide the dimensions of my box. However the final design I used is the same as Papanikolaou`s box in his Darkroom Timer project. Many thanks to both of them! 4 x 15W Black Light UVA fluorescent lamps with a peak of radiation at ~350nm. Those lamps are suitable for photochemical procedures and can usually be used in insect killing. Examples are F15W/T8/BL from Syllvania and Actinic BL from Phillips There are twoidentical modules connected in parallel.

In each module, initially, the AC current flows through the two starters and the ballast. After a while one of the starters goes open-circuited and the current in the circuit is halted. This brings the ballast inductor in an extremely uncomfortable situation and it reacts violently developing a great voltage across its terminals. The value of the voltage can be as large as some kV and that is exactly what the fluorescent lamps need in order to be turned on.

After that transition effect the voltage accross each lamp gets stabillized around the 50~60V which is the lamp`s operation voltage shown in the manuals. Second, on the other side of the shelf, I screwed the eight G13 lamp holders, having first, drilled the holes needed by the wires to join the lamp bases with the starter bases.

As for the Software part I wrote the code in C using the winAVR and avr-gcc plugin along with avrStudio. Using ProteusVSM I tested the code in simulation environment which saved me a lot of effort and time.

Then I downloaded the hex code to the chip with the STK500. I strongly recommend 🔗 External reference