PIC hydro system controller

The ELC presented here has some flexibility, thanks to being software-controlled, but also has its limitations: It's intended for microhydro systems that employ a single-phase synchronous alternator, working at 220-240V, 50Hz, in a power range up to 25 kilowatts, and using up to eight dump loads, some or all of which can be "useful" loads, such as water boilers or room heaters. It can be built for 120V systems too, simply by using the proper power transformer, but then it will be limited to half the power. It can also be configured for 60Hz (or any other reasonable frequency) simply by setting a parameter in the software. In the form presented here, four of the outputs are used in prioritized fashion, with the other four having all the same (last) priority, with power being distributed among them. This can be changed in the software too, allowing any combination from fully sequentially prioritized, to fully "democratic" among all outputs.

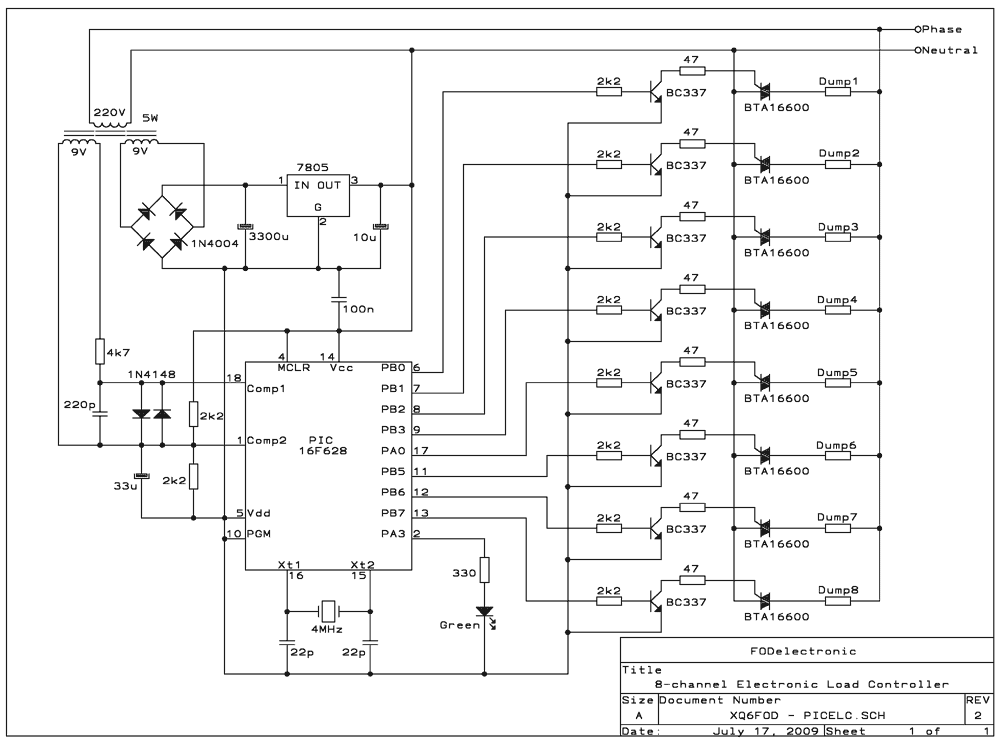

This ELC uses a quartz crystal for reference, and in normal operation it locks the generator/turbine speed to this quartz, resulting in highly accurate frequency control. The software allows fine tuning of the frequency. However, if a heavy load change momentarily pulls the system out of lock, the resulting missing or surplus cycles will not be recovered; instead the system will try to recover the correct speed as quickly as possible. For this reason, in the presence of such transient loads it might not be stable enough to accurately run clocks that use the line frequency for reference, despite having quartz control. I have no line-frequency-dependent clock, so I haven't tested how accurate such a clock is with this ELC. The core of this ELC is a PIC microcontroller. I used a 16F628, which is one of the most common PICs, inexpensive, easy to get, and quite powerful and versatile. It also has just about the right number of pins for this application. The whole ELC consists of little more than this PIC, the power supply, and the power circuit built around eight TRIACs.

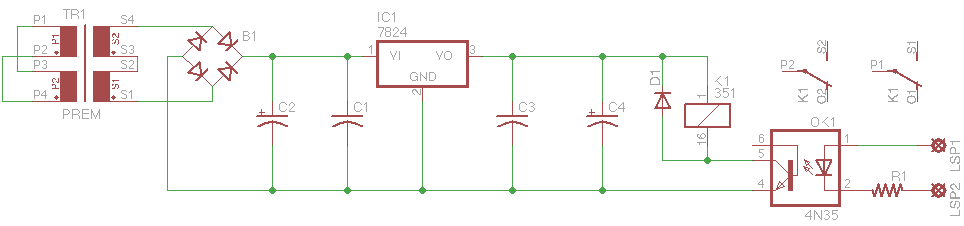

The power transformer has two secondaries. One of them is used to power the circuit, by means of a totally conventional circuit using a bridge rectifier, filter capacitor, and three-terminal regulator. The other secondary is used to feed the line frequency to the PIC, via a simple biasing and limiting circuit. The PIC uses one of its internal analog comparators to detect the zero crossings of the input waveform.

The power circuit uses TRIACs rated at 16 amperes each. This allows controlling up to 3.5 kW on each of the eight outputs, as long as the TRIACs are properly heatsinked - which is easy to do, since these are internally insulated TRIACs, which can be directly bolted or clamped to a grounded heatsink. In practice, the highest load I use on a single channel is only 2.5kW, so that there is a lot of headroom available.

The electronic load controller (ELC) is designed for integration into microhydro systems utilizing a single-phase synchronous alternator, operating within a voltage range of 220-240V and a frequency of 50Hz, with a maximum output power capacity of 25 kilowatts. The system is capable of managing up to eight dump loads, which can include useful applications such as water heaters or room heaters. For applications requiring 120V, the design can be adapted through the use of an appropriate transformer, although this configuration will limit the power capacity to 12.5 kilowatts.

The ELC's software-based control allows for configuration adjustments, including operation at different frequencies, such as 60Hz, by modifying parameters within the software. The prioritization of output loads can also be customized through software settings, enabling a range of operational modes from strictly prioritized to equal distribution among outputs.

Central to the ELC's functionality is a quartz crystal that provides a stable frequency reference, allowing the system to maintain a precise generator/turbine speed. The control algorithm is designed to quickly re-establish the desired speed in the event of transient load changes, although this may affect the stability of frequency-dependent devices, such as clocks.

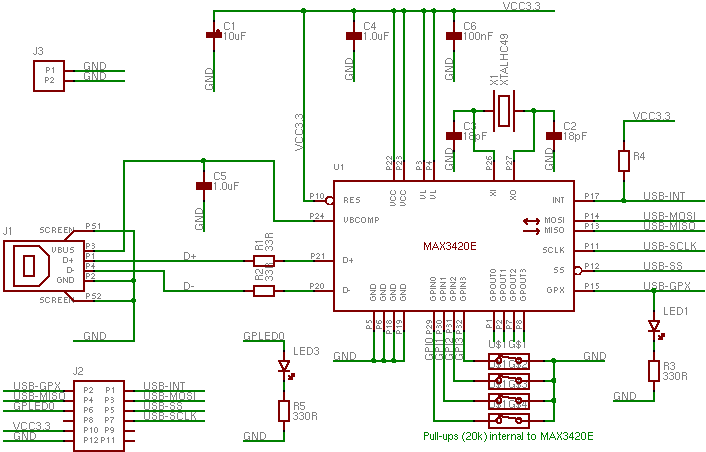

The ELC utilizes a Microchip PIC16F628 microcontroller, selected for its compatibility and sufficient I/O capabilities for this application. The circuit architecture incorporates a power supply derived from a transformer with dual secondary windings; one secondary powers the control circuitry through a bridge rectifier and filtering components, while the other provides line frequency input for zero-crossing detection via the PIC's internal comparator.

The TRIAC-based power control circuit is capable of handling significant loads, with each TRIAC rated for 16 amperes, allowing for safe operation of up to 3.5 kW per output channel, contingent upon adequate thermal management. The design employs insulated TRIACs, facilitating direct attachment to a grounded heatsink, thus ensuring reliable thermal performance even under substantial load conditions.The ELC presented here has some flexibility, thanks to being software-controlled, but also has its limitations: It's intended for microhydro systems that employ a single-phase synchronous alternator, working at 220-240V, 50Hz, in a power range up to 25 kilowatts, and using up to eight dump loads, some or all of which can be "useful" loads, such as water boilers or room heaters. It can be built for 120V systems too, simply by using the proper power transformer, but then it will be limited to half the power.

It can also be configured for 60Hz (or any other reasonable frequency) simply by setting a parameter in the software. In the form presented here, four of the outputs are used in prioritized fashion, with the other four having all the same (last) priority, with power being distributed among them.

This can be changed in the software too, allowing any combination from fully sequentially prioritized, to fully "democratic" among all outputs. This ELC uses a quartz crystal for reference, and in normal operation it locks the generator/turbine speed to this quartz, resulting in highly accurate frequency control.

The software allows fine tuning of the frequency. However, if a heavy load change momentarily pulls the system out of lock, the resulting missing or surplus cycles will not be recovered; instead the system will try to recover the correct speed as quickly as possible. For this reason, in the presence of such transient loads it might not be stable enough to accurately run clocks that use the line frequency for reference, despite having quartz control.

I have no line-frequency-dependent clock, so I haven't tested how accurate such a clock is with this ELC. The core of this ELC is a PIC microcontroller. I used a 16F628, which is one of the most common PICs, inexpensive, easy to get, and quite powerful and versatile.

It also has just about the right number of pins for this application. The whole ELC consists of little more than this PIC, the power supply, and the power circuit built around eight TRIACs. The power transformer has two secondaries. One of them is used to power the circuit, by means of a totally conventional circuit using a bridge rectifier, filter capacitor, and three-terminal regulator.

The other secondary is used to feed the line frequency to the PIC, via a simple biasing and limiting circuit. The PIC uses one of its internal analog comparators to detect the zero crossings of the input waveform.

The power circuit uses TRIACs rated at 16 amperes each. This allows controlling up to 3.5 kW on each of the eight outputs, as long as the TRIACs are properly heatsinked - which is easy to do, since these are internally insulated TRIACs, which can be directly bolted or clamped to a grounded heatsink. In practice, the highest load I use on a single channel is only 2.5kW, so that there is a lot of headroom available.

🔗 External reference

This ELC uses a quartz crystal for reference, and in normal operation it locks the generator/turbine speed to this quartz, resulting in highly accurate frequency control. The software allows fine tuning of the frequency. However, if a heavy load change momentarily pulls the system out of lock, the resulting missing or surplus cycles will not be recovered; instead the system will try to recover the correct speed as quickly as possible. For this reason, in the presence of such transient loads it might not be stable enough to accurately run clocks that use the line frequency for reference, despite having quartz control. I have no line-frequency-dependent clock, so I haven't tested how accurate such a clock is with this ELC. The core of this ELC is a PIC microcontroller. I used a 16F628, which is one of the most common PICs, inexpensive, easy to get, and quite powerful and versatile. It also has just about the right number of pins for this application. The whole ELC consists of little more than this PIC, the power supply, and the power circuit built around eight TRIACs.

The power transformer has two secondaries. One of them is used to power the circuit, by means of a totally conventional circuit using a bridge rectifier, filter capacitor, and three-terminal regulator. The other secondary is used to feed the line frequency to the PIC, via a simple biasing and limiting circuit. The PIC uses one of its internal analog comparators to detect the zero crossings of the input waveform.

The power circuit uses TRIACs rated at 16 amperes each. This allows controlling up to 3.5 kW on each of the eight outputs, as long as the TRIACs are properly heatsinked - which is easy to do, since these are internally insulated TRIACs, which can be directly bolted or clamped to a grounded heatsink. In practice, the highest load I use on a single channel is only 2.5kW, so that there is a lot of headroom available.

The electronic load controller (ELC) is designed for integration into microhydro systems utilizing a single-phase synchronous alternator, operating within a voltage range of 220-240V and a frequency of 50Hz, with a maximum output power capacity of 25 kilowatts. The system is capable of managing up to eight dump loads, which can include useful applications such as water heaters or room heaters. For applications requiring 120V, the design can be adapted through the use of an appropriate transformer, although this configuration will limit the power capacity to 12.5 kilowatts.

The ELC's software-based control allows for configuration adjustments, including operation at different frequencies, such as 60Hz, by modifying parameters within the software. The prioritization of output loads can also be customized through software settings, enabling a range of operational modes from strictly prioritized to equal distribution among outputs.

Central to the ELC's functionality is a quartz crystal that provides a stable frequency reference, allowing the system to maintain a precise generator/turbine speed. The control algorithm is designed to quickly re-establish the desired speed in the event of transient load changes, although this may affect the stability of frequency-dependent devices, such as clocks.

The ELC utilizes a Microchip PIC16F628 microcontroller, selected for its compatibility and sufficient I/O capabilities for this application. The circuit architecture incorporates a power supply derived from a transformer with dual secondary windings; one secondary powers the control circuitry through a bridge rectifier and filtering components, while the other provides line frequency input for zero-crossing detection via the PIC's internal comparator.

The TRIAC-based power control circuit is capable of handling significant loads, with each TRIAC rated for 16 amperes, allowing for safe operation of up to 3.5 kW per output channel, contingent upon adequate thermal management. The design employs insulated TRIACs, facilitating direct attachment to a grounded heatsink, thus ensuring reliable thermal performance even under substantial load conditions.The ELC presented here has some flexibility, thanks to being software-controlled, but also has its limitations: It's intended for microhydro systems that employ a single-phase synchronous alternator, working at 220-240V, 50Hz, in a power range up to 25 kilowatts, and using up to eight dump loads, some or all of which can be "useful" loads, such as water boilers or room heaters. It can be built for 120V systems too, simply by using the proper power transformer, but then it will be limited to half the power.

It can also be configured for 60Hz (or any other reasonable frequency) simply by setting a parameter in the software. In the form presented here, four of the outputs are used in prioritized fashion, with the other four having all the same (last) priority, with power being distributed among them.

This can be changed in the software too, allowing any combination from fully sequentially prioritized, to fully "democratic" among all outputs. This ELC uses a quartz crystal for reference, and in normal operation it locks the generator/turbine speed to this quartz, resulting in highly accurate frequency control.

The software allows fine tuning of the frequency. However, if a heavy load change momentarily pulls the system out of lock, the resulting missing or surplus cycles will not be recovered; instead the system will try to recover the correct speed as quickly as possible. For this reason, in the presence of such transient loads it might not be stable enough to accurately run clocks that use the line frequency for reference, despite having quartz control.

I have no line-frequency-dependent clock, so I haven't tested how accurate such a clock is with this ELC. The core of this ELC is a PIC microcontroller. I used a 16F628, which is one of the most common PICs, inexpensive, easy to get, and quite powerful and versatile.

It also has just about the right number of pins for this application. The whole ELC consists of little more than this PIC, the power supply, and the power circuit built around eight TRIACs. The power transformer has two secondaries. One of them is used to power the circuit, by means of a totally conventional circuit using a bridge rectifier, filter capacitor, and three-terminal regulator.

The other secondary is used to feed the line frequency to the PIC, via a simple biasing and limiting circuit. The PIC uses one of its internal analog comparators to detect the zero crossings of the input waveform.

The power circuit uses TRIACs rated at 16 amperes each. This allows controlling up to 3.5 kW on each of the eight outputs, as long as the TRIACs are properly heatsinked - which is easy to do, since these are internally insulated TRIACs, which can be directly bolted or clamped to a grounded heatsink. In practice, the highest load I use on a single channel is only 2.5kW, so that there is a lot of headroom available.

🔗 External reference