picaxe

Over the weekend, an attempt was made to perform mechanical work by machining acrylic material to create a joint using a stepper motor. The effort was unsuccessful, particularly when trying to score and snap the acrylic, as cutting lengths longer than 10 cm proved to be challenging. A hacksaw was found to be a more effective tool, but the lack of proper benches and a vice hindered the quality of the work. There is now consideration being given to having a component manufactured. However, starting the design process has been difficult due to the blank screen presented by the CAD software, which is delaying the robot arm project. Various components were purchased from eBay, including Picaxe-compatible kits for prototyping, specifically Picaxe-08 kits for compact stepper motor controls. Additionally, inspired by kite aerial photography and RC videos, a 6-channel transmitter and receiver were acquired, which function well with the existing servos. Several more projects are anticipated.

The project involves the integration of several components to achieve a functional robotic arm. The decision to utilize a stepper motor for joint movement indicates an emphasis on precision and control in the arm's operation. Stepper motors are ideal for applications requiring accurate positioning, which is critical for tasks such as photography or complex manipulations.

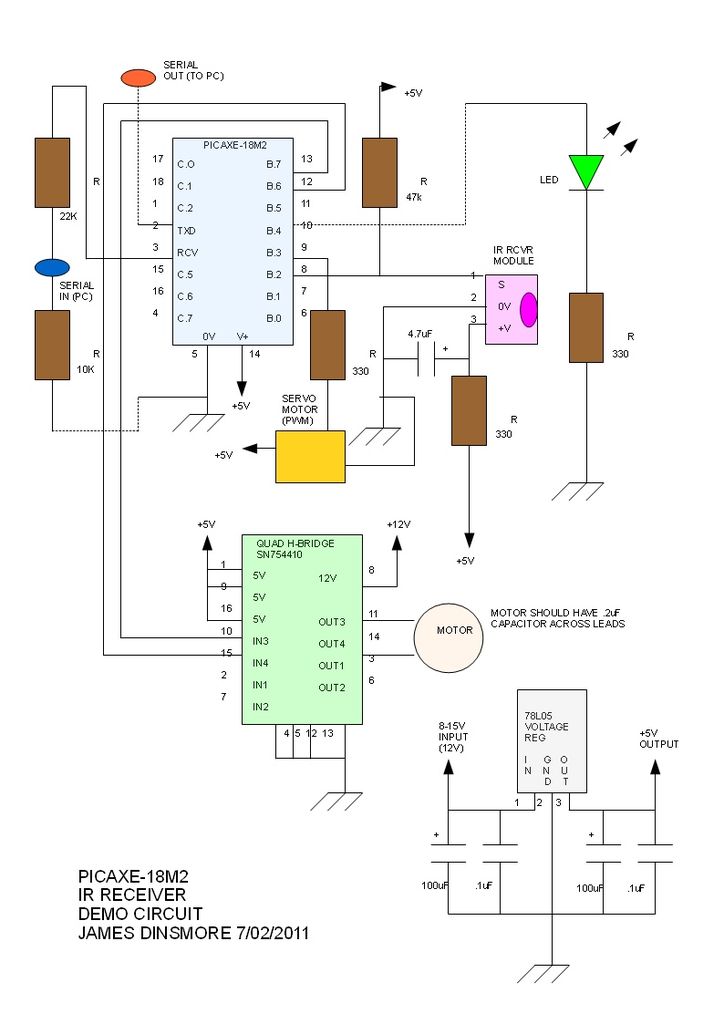

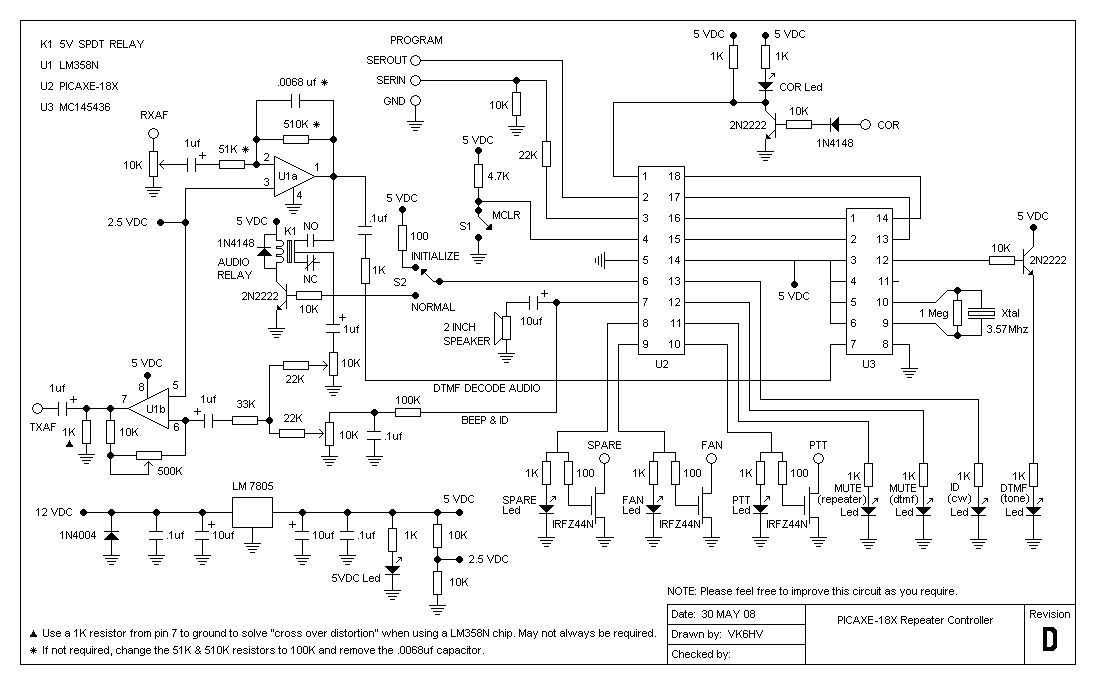

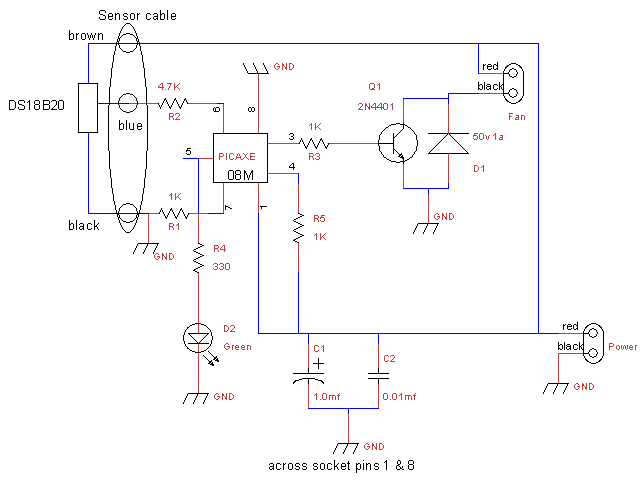

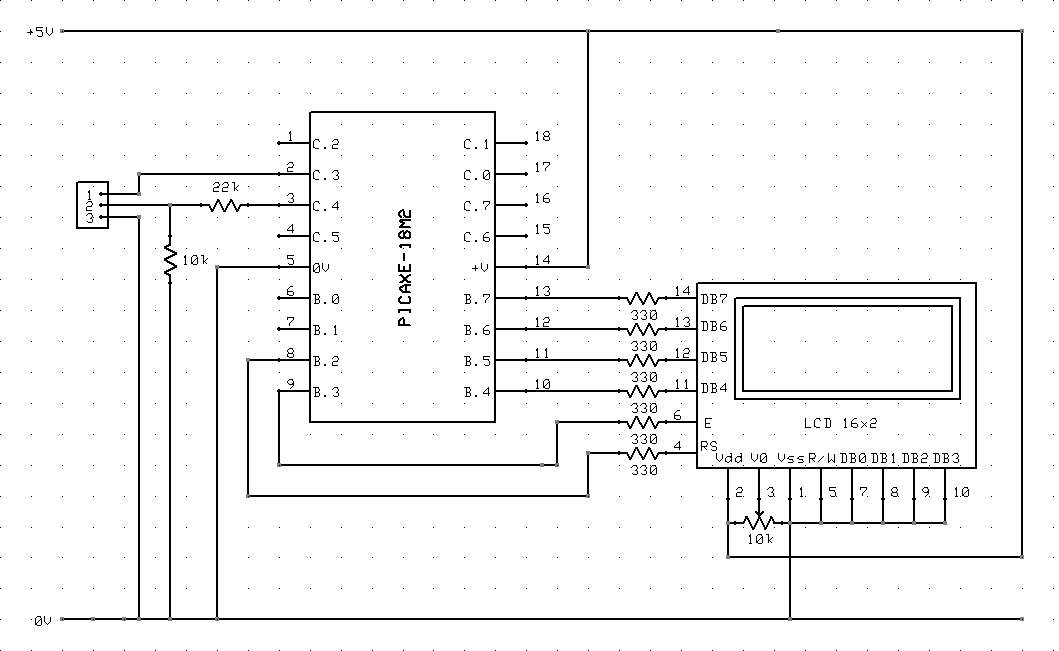

The Picaxe-08 kits will serve as the microcontroller backbone for the project, allowing for programming and control of the stepper motors. These kits provide an accessible platform for prototyping, enabling the user to develop and test control algorithms effectively. The compact design of the Picaxe-08 is particularly suitable for integration into smaller robotic systems where space is at a premium.

The radio control system, consisting of a 6-channel transmitter and receiver, adds another layer of functionality to the robotic arm. This system allows for remote operation, which can be particularly useful for applications such as aerial photography, where the arm may need to be positioned at a distance. The compatibility with existing servos suggests that the project will incorporate various actuators for movement, enhancing the versatility of the robotic arm.

Overall, the combination of these components lays a solid foundation for the development of a sophisticated robotic arm capable of executing a range of tasks. Future projects may expand on this foundation, exploring more advanced control systems, additional sensors for feedback, and enhanced functionality through the incorporation of new technologies.I had a go at doing some mechanical work at the weekend. I tried to machine the acrylic I bought and create some kind of joint using a stepper motor. I have to say that I failed rather miserably! I tried scoring and snapping the stuff only to find that a cut length of anything longer than about 10cm was impossible! A hacksaw proved much better but I really don`t have the benches, vice, etc to make a decent job of it. I`m now thinking about getting something made up. The problem with that is that I`m finding it difficult to start designing when faced with a blank screen on a CAD package. It is holding the robot arm project up though. I purchased some bits off ebay. Firstly I bought some Picaxe compatible kits to help me prototype. Some of these are Picaxe-08 kits so I shall be making some compact stepper motor controls shortly. They were from rkeducation (they also have a web site ). Secondly, inspired by a kite aerial photography (and some RC ) videos I decided to buy some radio gear.

I now have a 6 channel transmitter and receiver which work well with the servos I have. I see a few more projects coming up 🔗 External reference

The project involves the integration of several components to achieve a functional robotic arm. The decision to utilize a stepper motor for joint movement indicates an emphasis on precision and control in the arm's operation. Stepper motors are ideal for applications requiring accurate positioning, which is critical for tasks such as photography or complex manipulations.

The Picaxe-08 kits will serve as the microcontroller backbone for the project, allowing for programming and control of the stepper motors. These kits provide an accessible platform for prototyping, enabling the user to develop and test control algorithms effectively. The compact design of the Picaxe-08 is particularly suitable for integration into smaller robotic systems where space is at a premium.

The radio control system, consisting of a 6-channel transmitter and receiver, adds another layer of functionality to the robotic arm. This system allows for remote operation, which can be particularly useful for applications such as aerial photography, where the arm may need to be positioned at a distance. The compatibility with existing servos suggests that the project will incorporate various actuators for movement, enhancing the versatility of the robotic arm.

Overall, the combination of these components lays a solid foundation for the development of a sophisticated robotic arm capable of executing a range of tasks. Future projects may expand on this foundation, exploring more advanced control systems, additional sensors for feedback, and enhanced functionality through the incorporation of new technologies.I had a go at doing some mechanical work at the weekend. I tried to machine the acrylic I bought and create some kind of joint using a stepper motor. I have to say that I failed rather miserably! I tried scoring and snapping the stuff only to find that a cut length of anything longer than about 10cm was impossible! A hacksaw proved much better but I really don`t have the benches, vice, etc to make a decent job of it. I`m now thinking about getting something made up. The problem with that is that I`m finding it difficult to start designing when faced with a blank screen on a CAD package. It is holding the robot arm project up though. I purchased some bits off ebay. Firstly I bought some Picaxe compatible kits to help me prototype. Some of these are Picaxe-08 kits so I shall be making some compact stepper motor controls shortly. They were from rkeducation (they also have a web site ). Secondly, inspired by a kite aerial photography (and some RC ) videos I decided to buy some radio gear.

I now have a 6 channel transmitter and receiver which work well with the servos I have. I see a few more projects coming up 🔗 External reference