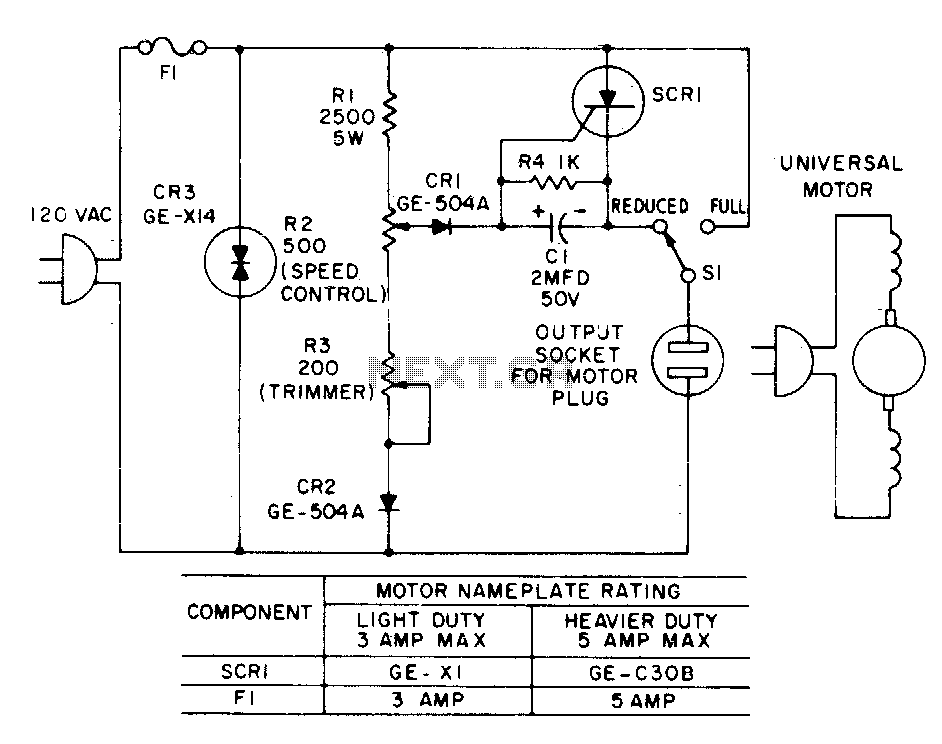

Plug-in speed control for tools or appliances

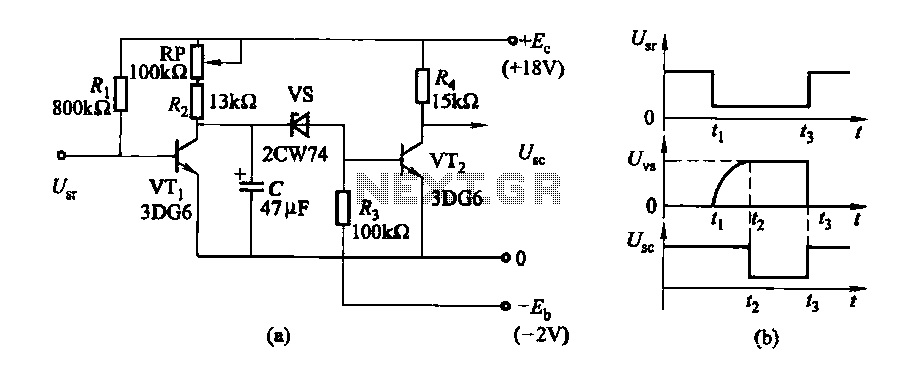

Most standard household appliances and portable hand tools can be adapted for variable-speed operation using a simple half-wave SCR phase control. This device can serve as the speed control unit for typical loads, provided they utilize series universal (brush type) motors. During the positive half-cycle of the supply voltage, the arm of potentiometer R2 taps off a fraction of the sine wave supply voltage and compares it with the counter electromotive force (emf) of the motor through the gate of the SCR. When the voltage from the potentiometer exceeds the armature voltage, current flows through CR1 into the gate of the SCR, triggering it and applying the remaining portion of that half-cycle supply voltage to the motor. The speed at which the motor operates can be adjusted using R2. Stable operation is achievable over an approximate speed range of 3 to 1.

The described circuit employs a half-wave silicon-controlled rectifier (SCR) phase control technique for regulating the speed of universal motors commonly found in household appliances and power tools. The circuit's operation is predicated on the relationship between the voltage derived from the potentiometer R2 and the back electromotive force (back EMF) produced by the motor.

In this configuration, the SCR acts as a switch that can be turned on at a specific point in the AC cycle. The potentiometer R2 is connected in such a way that it can adjust the voltage fed to the gate of the SCR. As the potentiometer is adjusted, the voltage at its output varies, allowing for fine control over the point in the AC cycle at which the SCR is triggered. When this voltage exceeds the back EMF of the motor, the SCR conducts, allowing current to flow through the motor for the remainder of that half-cycle.

This method of control is effective in providing a variable speed range for the motor, enabling it to operate efficiently at different speeds based on the requirements of the task at hand. The design incorporates a feedback mechanism through the back EMF, ensuring that the speed control remains stable across a wide range of operating conditions. The circuit is particularly advantageous in applications where precise speed control is necessary, such as in drills, saws, and other tools that require variable speed for different materials or tasks.

Overall, this SCR phase control circuit offers a straightforward and efficient means of achieving variable-speed operation in brush-type motors, enhancing the versatility and functionality of standard household appliances and portable tools.Most standard household appliances and portable hand tools can be adapted to variable -speed operation by use of this simple half-wave SCR phase control. It can be used as the speed control unit for the following typical loads pro-videe they use series universal (brush type) motors.

During the positive half cycle of the supply voltage, the arm on potentiometer R2 taps off a traction of the sine wave supply voltage and compares it with the counter emf of the motor through the gate of the SCR When the pot voltage rises above the armature voltage, current flows through CRI into the gate of the SCR, triggering it, and thus applying the remainder of that half cycle supply voltage to the motor. The speed at which the motor operates can be selected by R2. Stable operation is possible over approximately a 3-to-l speed range.

The described circuit employs a half-wave silicon-controlled rectifier (SCR) phase control technique for regulating the speed of universal motors commonly found in household appliances and power tools. The circuit's operation is predicated on the relationship between the voltage derived from the potentiometer R2 and the back electromotive force (back EMF) produced by the motor.

In this configuration, the SCR acts as a switch that can be turned on at a specific point in the AC cycle. The potentiometer R2 is connected in such a way that it can adjust the voltage fed to the gate of the SCR. As the potentiometer is adjusted, the voltage at its output varies, allowing for fine control over the point in the AC cycle at which the SCR is triggered. When this voltage exceeds the back EMF of the motor, the SCR conducts, allowing current to flow through the motor for the remainder of that half-cycle.

This method of control is effective in providing a variable speed range for the motor, enabling it to operate efficiently at different speeds based on the requirements of the task at hand. The design incorporates a feedback mechanism through the back EMF, ensuring that the speed control remains stable across a wide range of operating conditions. The circuit is particularly advantageous in applications where precise speed control is necessary, such as in drills, saws, and other tools that require variable speed for different materials or tasks.

Overall, this SCR phase control circuit offers a straightforward and efficient means of achieving variable-speed operation in brush-type motors, enhancing the versatility and functionality of standard household appliances and portable tools.Most standard household appliances and portable hand tools can be adapted to variable -speed operation by use of this simple half-wave SCR phase control. It can be used as the speed control unit for the following typical loads pro-videe they use series universal (brush type) motors.

During the positive half cycle of the supply voltage, the arm on potentiometer R2 taps off a traction of the sine wave supply voltage and compares it with the counter emf of the motor through the gate of the SCR When the pot voltage rises above the armature voltage, current flows through CRI into the gate of the SCR, triggering it, and thus applying the remainder of that half cycle supply voltage to the motor. The speed at which the motor operates can be selected by R2. Stable operation is possible over approximately a 3-to-l speed range.