Pulse Width Modulation

The control of electric motors is a topic of interest for those involved in Meccano model building. Each model has specific motor requirements concerning available space, motor power, speed, frequency of start and stop, and the necessity for reduction gearing. While straightforward control methods like a regulated voltage supply, an on/off switch, and motor reversal capabilities may seem sufficient, they often yield unrealistic results. A significant issue is poor starting performance, where the motor tends to jump from a stationary position to over half speed almost instantly. This behavior is attributed to the motor's starting characteristics, which can be reluctant under load. When stationary, a motor exhibits low resistance. As the speed control is advanced, current increases, but the voltage across the motor remains low. Consequently, the speed control must be significantly advanced before the voltage and power provided to the motor are sufficient to overcome its starting reluctance. Changes in motor speed and load also lead to variations in internal resistance, resulting in poor speed regulation, particularly at low speeds. An analogy can be drawn to bicycle riding, where pedaling (exerting energy) is alternated with coasting (using momentum). The 'duty cycle' represents the ratio of pedaling time to total time. A 100% duty cycle indicates constant pedaling, while a 50% duty cycle signifies pedaling for half the time. Pulse Width Modulation (PWM) for motor speed control operates similarly. Instead of varying the voltage supplied to the motor, a fixed voltage (e.g., 12V) is applied to initiate immediate spinning. The voltage is then removed, allowing the motor to coast. By continuously cycling the voltage on and off with a varying duty cycle, motor speed can be regulated. The waveforms illustrate this control method, where maximum and minimum voltages are 12V and 0V, respectively. In waveform 1a, the signal has a 1:1 mark-space ratio, resulting in an average voltage of 6V and half-speed operation. In waveform 1b, a 3:1 ratio yields an average output of 9V, resulting in three-quarters speed. Conversely, waveform 1c, with a 1:3 ratio, provides an average output of 3V, leading to one-quarter speed. By adjusting the mark-space ratio, any desired average output voltage between 0V and 12V can be achieved. Proper operation of the motor is contingent upon setting the pulsed signal frequency correctly, with a suitable frequency around 30Hz. Frequencies that are too low may cause jerky operation, while excessively high frequencies can increase motor impedance. PWM inherently requires timing, which can be accomplished using two 555 timer ICs and potentiometers to generate the PWM signal. Given that PWM produces a digital on/off signal, it can also be easily generated using a PC or microcontroller, though this is beyond the scope of the current discussion. The circuit utilizes two 555 ICs and combines two types of circuits, with the first functioning as a free-running multivibrator (astable) with an adjustable frequency around 30Hz.

The control of electric motors in model building applications necessitates a comprehensive understanding of both the electrical characteristics of the motors and the control methods employed. The use of PWM offers a sophisticated approach to managing motor speed and performance, mitigating issues associated with traditional control methods. The integration of 555 timer ICs into the circuit design enables precise frequency generation and duty cycle manipulation, which are crucial for achieving smooth motor operation.

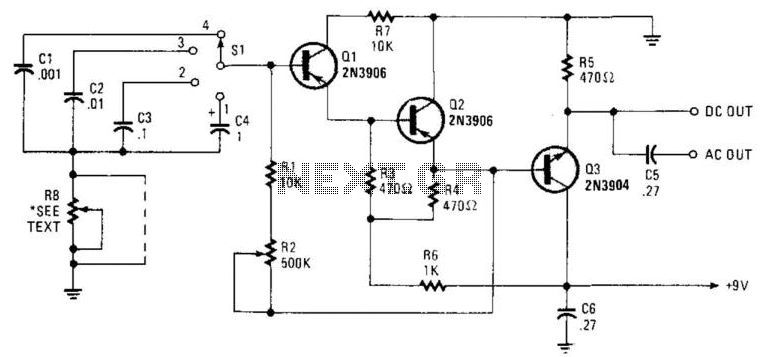

In practical applications, the design of the PWM circuit begins with configuring the 555 timer in astable mode, where the timing components—resistors and capacitors—determine the frequency of the output signal. The duty cycle can be adjusted using potentiometers, allowing for fine-tuning of the motor speed. The output from the 555 timer is then fed into a transistor circuit, which acts as a switch to control the power delivered to the motor. By varying the duty cycle of the PWM signal, the average voltage supplied to the motor can be modulated, resulting in variable speed control.

Additional considerations in the design include ensuring that the components can handle the current and voltage levels required by the motor. Heat dissipation and protection circuitry, such as diodes for back EMF protection, are also critical to maintaining circuit integrity and prolonging component life. The choice of components, including the type of motor used, will influence the performance characteristics of the entire system, necessitating careful selection based on the specific application requirements.

Overall, the application of PWM in motor control within Meccano model building not only enhances performance but also allows for greater flexibility in design, enabling builders to create more complex and dynamic models.The control of electric motors is something which interests nearly everyone involved with Meccano model building. Every model has its own motor requirements with regard to the space available, the power of the motor, its speed, whether it must stop and start frequently, and the need for reduction gearing.

On the face of it, simple methods of contr ol are perfectly adequate, with a regulated voltage supply, a simple on/off switch, and the means to reverse the motor. Speed can be controlled with a wire-wound potentiometer (variable resistor) or a circuit such as the Darlington Pair Speed Control.

In reality, these methods can provide very unrealistic results. The main problem is poor starting performance, the motor tending to jump almost instantly from a stationary position to what is often more than half speed. The main cause of this seems to be the starting characteristic of the motor itself which when under load seems reluctant to start.

A motor has a relatively low resistance when it is stationary. As the speed control is advanced, the current through the motor increases, but the voltage across the motor remains quite low. The speed control therefore has to be well advanced before the voltage and power fed to the motor are high enough to overcome its reluctance to start.

As the motor speed and the load on it changes, there are changes in its internal resistance. Speed regulation is not very good under these circumstances, particularly at low speed. A good analogy is bicycle riding. You peddle (exert energy) and then coast (relax) using your momentum to carry you forward. As you slow down (due to wind resistance, friction, road shape) you peddle to speed up and then coast again. The `duty cycle` is the ratio of peddling time to the total time (peddle + coast time). A 100% duty cycle means you are peddling all the time, and a 50% duty cycle means you are peddling only half the time.

PWM for motor speed control works in a very similar way. Instead of supplying a varying voltage to a motor, it is supplied with a fixed voltage value (such as 12V) which starts it spinning immediately. The voltage is then removed and the motor `coasts`. By continuing this voltage on/off cycle with a varying duty cycle, the motor speed can be controlled.

The waveforms in figure 1 help to explain the way in which this method of control operates. In each case the signal has maximum and minimum voltages of 12V and 0V. In waveform 1a, the signal has a mark-space ratio of 1:1. With the signal at 12V for 50% of the time, the average voltage is 6V, so the motor runs at half its maximum speed. In waveform 1b, the signal has a mark-space ratio of 3:1, which means that the output is at 12V for 75% of the time.

This clearly gives an average output voltage of 9V, so the motor runs at 3/4 of its maximum speed. In waveform 1c, the signal has a mark-space ratio is 1:3, giving an output signal that is 12V for just 25% of the time. The average output voltage of this signal is just 3V, so the motor runs at 1/4 of its maximum speed. By varying the mark-space ratio of the signal over the full range, it is possible to obtain any desired average output voltage from 0V to 12V.

The motor will work perfectly well, provided that the frequency of the pulsed signal is set correctly, a suitable frequency being 30Hz. Setting the frequency too low gives jerky operation, and setting it too high might increase the motor`s impedance.

The concept of PWM inherently requires timing. Two 555 timer ICs and some potentiometers can be used to generate a PWM signal, and since PWM provides a digital, on/off signal, it is also easy to use a PC or micro-controller to create the signal; however this is beyond the scope of this article. The circuit in figure 2 uses two 555 ICs and is actually a combination of two types of circuit. The first is a free running multivibrator (astable) with an adjustable frequency around 30Hz. The output 🔗 External reference

The control of electric motors in model building applications necessitates a comprehensive understanding of both the electrical characteristics of the motors and the control methods employed. The use of PWM offers a sophisticated approach to managing motor speed and performance, mitigating issues associated with traditional control methods. The integration of 555 timer ICs into the circuit design enables precise frequency generation and duty cycle manipulation, which are crucial for achieving smooth motor operation.

In practical applications, the design of the PWM circuit begins with configuring the 555 timer in astable mode, where the timing components—resistors and capacitors—determine the frequency of the output signal. The duty cycle can be adjusted using potentiometers, allowing for fine-tuning of the motor speed. The output from the 555 timer is then fed into a transistor circuit, which acts as a switch to control the power delivered to the motor. By varying the duty cycle of the PWM signal, the average voltage supplied to the motor can be modulated, resulting in variable speed control.

Additional considerations in the design include ensuring that the components can handle the current and voltage levels required by the motor. Heat dissipation and protection circuitry, such as diodes for back EMF protection, are also critical to maintaining circuit integrity and prolonging component life. The choice of components, including the type of motor used, will influence the performance characteristics of the entire system, necessitating careful selection based on the specific application requirements.

Overall, the application of PWM in motor control within Meccano model building not only enhances performance but also allows for greater flexibility in design, enabling builders to create more complex and dynamic models.The control of electric motors is something which interests nearly everyone involved with Meccano model building. Every model has its own motor requirements with regard to the space available, the power of the motor, its speed, whether it must stop and start frequently, and the need for reduction gearing.

On the face of it, simple methods of contr ol are perfectly adequate, with a regulated voltage supply, a simple on/off switch, and the means to reverse the motor. Speed can be controlled with a wire-wound potentiometer (variable resistor) or a circuit such as the Darlington Pair Speed Control.

In reality, these methods can provide very unrealistic results. The main problem is poor starting performance, the motor tending to jump almost instantly from a stationary position to what is often more than half speed. The main cause of this seems to be the starting characteristic of the motor itself which when under load seems reluctant to start.

A motor has a relatively low resistance when it is stationary. As the speed control is advanced, the current through the motor increases, but the voltage across the motor remains quite low. The speed control therefore has to be well advanced before the voltage and power fed to the motor are high enough to overcome its reluctance to start.

As the motor speed and the load on it changes, there are changes in its internal resistance. Speed regulation is not very good under these circumstances, particularly at low speed. A good analogy is bicycle riding. You peddle (exert energy) and then coast (relax) using your momentum to carry you forward. As you slow down (due to wind resistance, friction, road shape) you peddle to speed up and then coast again. The `duty cycle` is the ratio of peddling time to the total time (peddle + coast time). A 100% duty cycle means you are peddling all the time, and a 50% duty cycle means you are peddling only half the time.

PWM for motor speed control works in a very similar way. Instead of supplying a varying voltage to a motor, it is supplied with a fixed voltage value (such as 12V) which starts it spinning immediately. The voltage is then removed and the motor `coasts`. By continuing this voltage on/off cycle with a varying duty cycle, the motor speed can be controlled.

The waveforms in figure 1 help to explain the way in which this method of control operates. In each case the signal has maximum and minimum voltages of 12V and 0V. In waveform 1a, the signal has a mark-space ratio of 1:1. With the signal at 12V for 50% of the time, the average voltage is 6V, so the motor runs at half its maximum speed. In waveform 1b, the signal has a mark-space ratio of 3:1, which means that the output is at 12V for 75% of the time.

This clearly gives an average output voltage of 9V, so the motor runs at 3/4 of its maximum speed. In waveform 1c, the signal has a mark-space ratio is 1:3, giving an output signal that is 12V for just 25% of the time. The average output voltage of this signal is just 3V, so the motor runs at 1/4 of its maximum speed. By varying the mark-space ratio of the signal over the full range, it is possible to obtain any desired average output voltage from 0V to 12V.

The motor will work perfectly well, provided that the frequency of the pulsed signal is set correctly, a suitable frequency being 30Hz. Setting the frequency too low gives jerky operation, and setting it too high might increase the motor`s impedance.

The concept of PWM inherently requires timing. Two 555 timer ICs and some potentiometers can be used to generate a PWM signal, and since PWM provides a digital, on/off signal, it is also easy to use a PC or micro-controller to create the signal; however this is beyond the scope of this article. The circuit in figure 2 uses two 555 ICs and is actually a combination of two types of circuit. The first is a free running multivibrator (astable) with an adjustable frequency around 30Hz. The output 🔗 External reference