Replacing old capacitors

Original components, when still functional, exhibit stability and are not subject to infant mortality. Individual opinions may vary based on personal experiences. However, responses can differ due to several factors: the quality of the design utilizing appropriate components, the type and quality of materials, and environmental conditions during the equipment's life and storage. Frequent discussions arise around specific models. Since many collectors of vintage radio equipment may find this topic relevant, a general discussion thread has been initiated for readers to share their experiences. A short circuit can typically be identified by low voltage and/or resistance values in the affected area. Often, shorted capacitors lead to additional issues, such as burned resistors or blown fuses. When any of these conditions occur, a shorted capacitor should be suspected unless another cause is identified. This failure is common in electrolytic capacitors that have fully dried out. If a faulty capacitor is located in the B+ filter section, it will produce a loud hum. In certain situations, such as in the cathode path of audio power amplifier tubes, a dried capacitor may even enhance sound quality. Open circuits can also occasionally occur in some polystyrene foil capacitors due to thermal stress on the leads. These failures can be attributed to various causes, including partial drying of electrolyte in aluminum capacitors, drying or alteration of impregnating oils or waxes in paper capacitors, moisture absorption in ceramic or paper dielectrics, small cracks in the silver coating of lacquered mica capacitors, and partial chipping of ceramic capacitors. A twenty-percent decrease in the capacitance of filter electrolytic capacitors is generally acceptable, whereas a five-percent variation in the value of ceramic capacitors in tuned RF circuits can shift the resonance out of the tuning range. A very high, yet finite resistance value can be measured across any capacitor. In paper capacitors, low resistance may be observed due to moisture absorption by the paper itself. Some leakage is permissible in many circuits, such as in decoupling paths of B+ distribution or low voltage sections. In other cases, such as in the coupling between audio frequency (AF) driver and AF power amplifier stages, leakage can shift the grid biasing of the power tube to positive values. In electrolytic capacitors, leakage is often caused by small holes in the dielectric oxide. Leakage current can be significantly high if capacitors have been left inactive for an extended period. In such cases, applying full operating voltage suddenly may lead to irreversible failures. The dielectric layer can be restored through a short reforming cycle. Paper foil capacitors, typically impregnated with wax or oil, have been used for general-purpose applications, ranging from about 1000 picofarads to over 10 microfarads. They remain in use today, often alongside plastic films, in various AC applications. High-quality paper capacitors can remain stable for over 70 years. However, certain types or batches may experience issues over time due to poor hermetic sealing, inadequate manufacturing processes, or unstable or hygroscopic impregnating fluids.

The overview of paper capacitors illustrates various types, where P1, P2, P3, and P4 are identified as poor quality, featuring glass bodies with tar sealing. P1 and P3 exhibit melted seals, with P1 losing its impregnating wax. P2 shows an unstuck tar seal, while P4 presents a swollen seal. P5, P6, and P7 represent paper capacitors that have maintained functionality.

The functionality and reliability of capacitors are critical in electronic circuits. Short circuits, open circuits, and leakage currents can significantly impact circuit performance. Identifying and addressing these issues is essential for maintaining the integrity of electronic equipment, especially vintage models where component aging is a common concern. Regular testing and maintenance can help prolong the lifespan of these components, ensuring optimal performance in various applications. Understanding the characteristics and failure mechanisms of different capacitor types aids in making informed decisions for repairs and replacements, ultimately enhancing the reliability of electronic systems.Original components, when still good, are stable and not subjected to infant mortality. Of course everybody has his own opinions derived from past experiences. Nevertheless answers may vary depending upon several reasons: quality of the design with proper use of right components, type and quality of materials, environmental conditions during life and storage of equipment. I see frequent discussions tied to specific models. Since almost every collector of old radio equipment may be interested in this topic, I decided to open a generic thread, hoping that readers would add their experiences. A short can be easily identified by low voltage and/or resistance values all around the faulty section.

Often shorted caps cause other faults, as burned resistors or blown fuses. Whenever one of the latter conditions is encountered, shorted capacitor should be suspected unless different cause is found. This failure is common in electrolytic capacitors, when fully dried. If faulty capacitor is in the B+ filter section, a loud hum will arise. In some circumstances, such as in the cathode path of audio power amplifier tubes, a dried capacitor could also give benefic effect on sound quality.

Opens can also be occasionally found in some polystyrene foil capacitors, due thermal stress on the leads. These may derive from different causes: partial drying of electrolyte in aluminum capacitors; drying or alteration of impregnating oils or waxes in paper capacitors; moisture adsorption in ceramic or in paper dielectric; small cracks in silver coating of some lacquered mica capacitors, partial chipping of ceramic capacitors.

A twenty-percent decrease in the capacitance of filter electrolytic capacitors may be tolerated, but a five-percent variation on the value of ceramic capacitors in tuned RF circuits may move resonance out of tuning range. A very high, but finite resistance value can be measured across any capacitor. In paper capacitors low resistance may be found because of moisture adsorbed by paper itself. Some leakage is acceptable in many circuits, as in decoupling paths of B+ distribution or in low voltage sections.

In other cases, as in the coupling between AF driver and AF power amplifier stage, leakage can move grid biasing of the power tube to positive values. In electrolytic capacitors leakage is due to small holes in dielectric oxide. Leakage current starts quite high when capacitors have been left inoperative for a long period. In this case, if full operating voltage is suddenly applied, leakage current may cause irreversible failures.

The dielectric layer can be easily repaired by a short reforming cycle. Paper foil Paper, usually impregnated with wax or oil, was used for general-purpose capacitors, ranging from about 1000 picofarads to over than 10 microfarads. It is still in use today, also in addition to plastic films, in many a. c. applications. Good paper capacitors stay still stable after over than 70 years. Some types or lots may give troubles in the years, due to poor hermetic sealing of their bodies, to poor manufacturing process or to unstable or hygroscopic impregnating fluids.

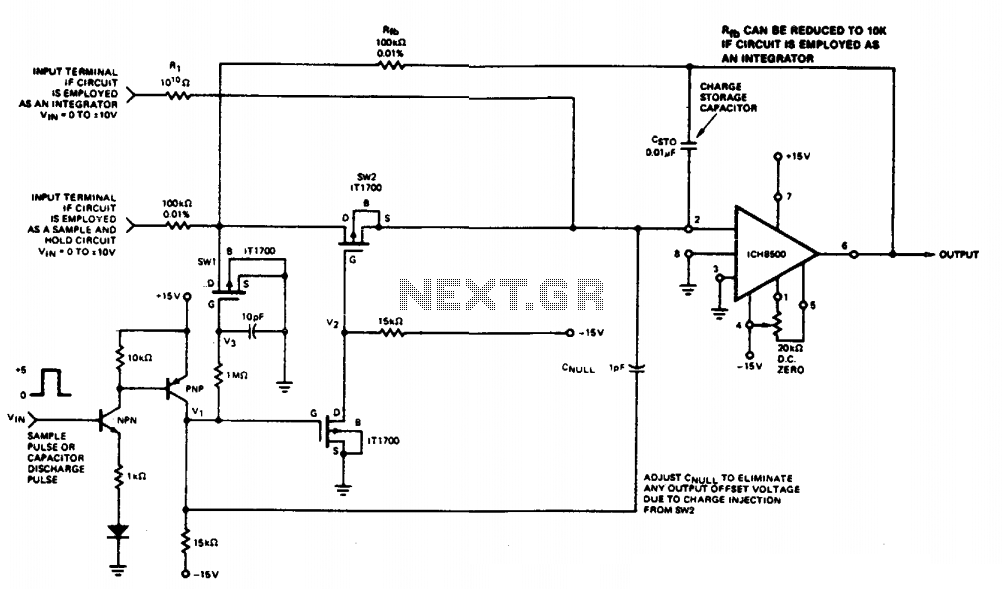

Pic. 1 Overview of paper capacitors. P1, P2, P3 and P4 are very poor types, with glass bodies and tar sealing. P1 and P3 show melted seals and P1 even lost its impregnating wax. P2 shows unstuck tar seal, P4 has swollen seal. P5, P6 and P7 are paper capaci 🔗 External reference

The overview of paper capacitors illustrates various types, where P1, P2, P3, and P4 are identified as poor quality, featuring glass bodies with tar sealing. P1 and P3 exhibit melted seals, with P1 losing its impregnating wax. P2 shows an unstuck tar seal, while P4 presents a swollen seal. P5, P6, and P7 represent paper capacitors that have maintained functionality.

The functionality and reliability of capacitors are critical in electronic circuits. Short circuits, open circuits, and leakage currents can significantly impact circuit performance. Identifying and addressing these issues is essential for maintaining the integrity of electronic equipment, especially vintage models where component aging is a common concern. Regular testing and maintenance can help prolong the lifespan of these components, ensuring optimal performance in various applications. Understanding the characteristics and failure mechanisms of different capacitor types aids in making informed decisions for repairs and replacements, ultimately enhancing the reliability of electronic systems.Original components, when still good, are stable and not subjected to infant mortality. Of course everybody has his own opinions derived from past experiences. Nevertheless answers may vary depending upon several reasons: quality of the design with proper use of right components, type and quality of materials, environmental conditions during life and storage of equipment. I see frequent discussions tied to specific models. Since almost every collector of old radio equipment may be interested in this topic, I decided to open a generic thread, hoping that readers would add their experiences. A short can be easily identified by low voltage and/or resistance values all around the faulty section.

Often shorted caps cause other faults, as burned resistors or blown fuses. Whenever one of the latter conditions is encountered, shorted capacitor should be suspected unless different cause is found. This failure is common in electrolytic capacitors, when fully dried. If faulty capacitor is in the B+ filter section, a loud hum will arise. In some circumstances, such as in the cathode path of audio power amplifier tubes, a dried capacitor could also give benefic effect on sound quality.

Opens can also be occasionally found in some polystyrene foil capacitors, due thermal stress on the leads. These may derive from different causes: partial drying of electrolyte in aluminum capacitors; drying or alteration of impregnating oils or waxes in paper capacitors; moisture adsorption in ceramic or in paper dielectric; small cracks in silver coating of some lacquered mica capacitors, partial chipping of ceramic capacitors.

A twenty-percent decrease in the capacitance of filter electrolytic capacitors may be tolerated, but a five-percent variation on the value of ceramic capacitors in tuned RF circuits may move resonance out of tuning range. A very high, but finite resistance value can be measured across any capacitor. In paper capacitors low resistance may be found because of moisture adsorbed by paper itself. Some leakage is acceptable in many circuits, as in decoupling paths of B+ distribution or in low voltage sections.

In other cases, as in the coupling between AF driver and AF power amplifier stage, leakage can move grid biasing of the power tube to positive values. In electrolytic capacitors leakage is due to small holes in dielectric oxide. Leakage current starts quite high when capacitors have been left inoperative for a long period. In this case, if full operating voltage is suddenly applied, leakage current may cause irreversible failures.

The dielectric layer can be easily repaired by a short reforming cycle. Paper foil Paper, usually impregnated with wax or oil, was used for general-purpose capacitors, ranging from about 1000 picofarads to over than 10 microfarads. It is still in use today, also in addition to plastic films, in many a. c. applications. Good paper capacitors stay still stable after over than 70 years. Some types or lots may give troubles in the years, due to poor hermetic sealing of their bodies, to poor manufacturing process or to unstable or hygroscopic impregnating fluids.

Pic. 1 Overview of paper capacitors. P1, P2, P3 and P4 are very poor types, with glass bodies and tar sealing. P1 and P3 show melted seals and P1 even lost its impregnating wax. P2 shows unstuck tar seal, P4 has swollen seal. P5, P6 and P7 are paper capaci 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713