salvage dc motor speed control

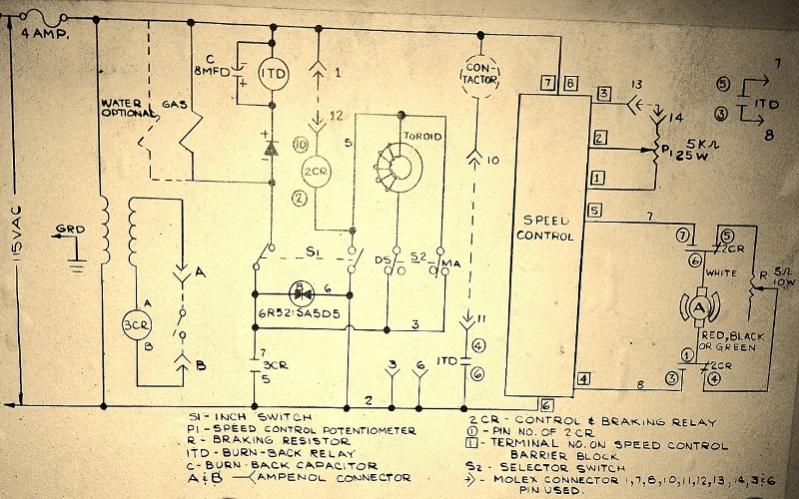

A Chemetron wire feeder is being utilized, and there is a desire to use the speed control from the control box to regulate the motor it originally contained.

The Chemetron wire feeder is designed for efficient wire feeding in welding applications. The integration of a speed control mechanism from the control box allows for precise regulation of the motor's speed, enhancing operational flexibility and performance.

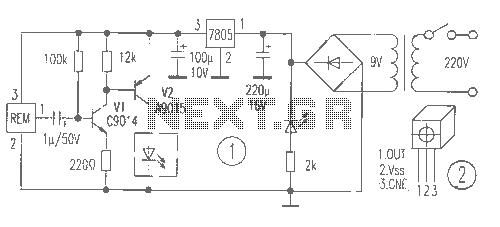

The proposed circuit should include a variable resistor or a pulse-width modulation (PWM) controller connected to the motor's input terminals. This setup will enable real-time adjustments to the motor speed based on user requirements.

To implement this effectively, the following components are recommended:

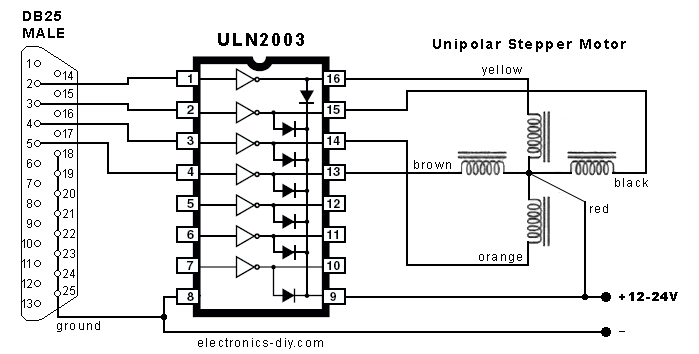

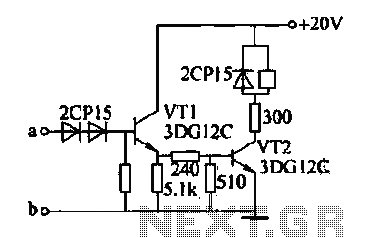

1. **Motor Driver Circuit**: A suitable motor driver circuit should be selected that can handle the voltage and current ratings of the motor. H-bridge configurations are commonly used for bidirectional control.

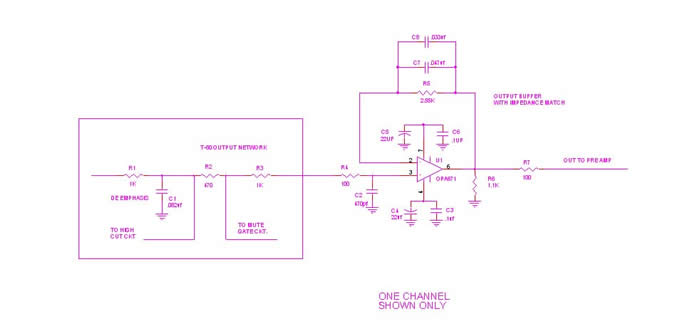

2. **Speed Control Interface**: The speed control can be achieved using a potentiometer or a PWM signal generator. If using PWM, ensure that the frequency is appropriate for the motor type to prevent overheating and ensure smooth operation.

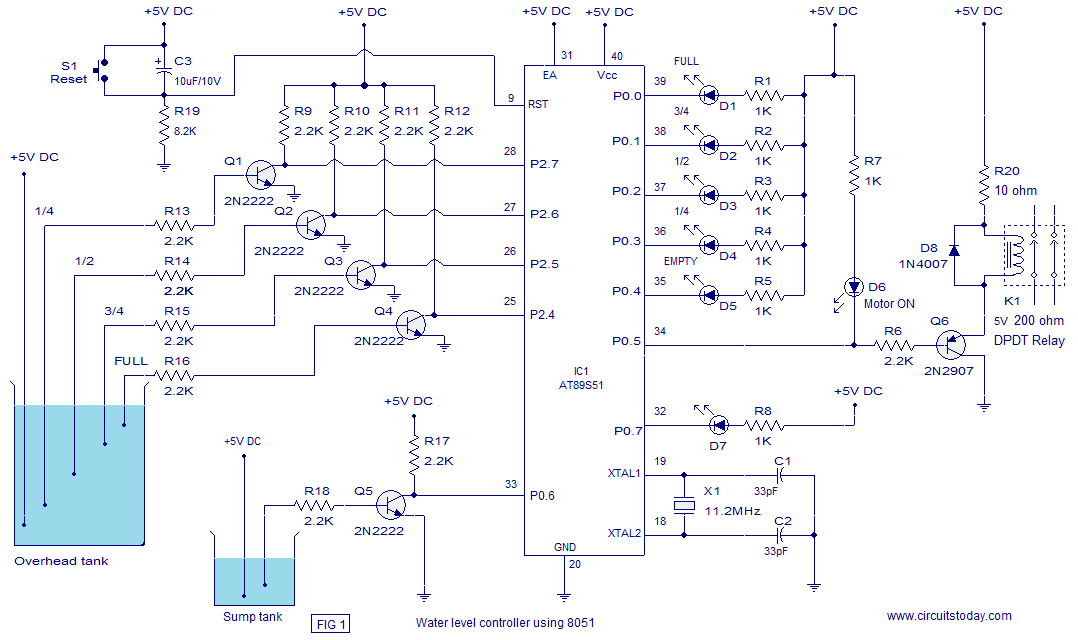

3. **Power Supply**: A stable power supply must be provided to ensure that the motor receives adequate voltage and current without fluctuations.

4. **Feedback Mechanism**: Incorporating a feedback mechanism, such as an encoder, can help in monitoring the motor speed, allowing for closed-loop control. This setup can enhance precision and responsiveness.

5. **Protection Circuitry**: It is advisable to include protection circuits such as fuses or circuit breakers to prevent damage to the motor and associated components in case of overload or short circuits.

By integrating these components into the existing wire feeder system, enhanced control over the motor speed will be achieved, leading to improved performance and versatility in its applications.I have a Chemetron wirefeeder that I am using the motor and I want to use the speed control out of the control box to control the nice motor it had in .. 🔗 External reference

The Chemetron wire feeder is designed for efficient wire feeding in welding applications. The integration of a speed control mechanism from the control box allows for precise regulation of the motor's speed, enhancing operational flexibility and performance.

The proposed circuit should include a variable resistor or a pulse-width modulation (PWM) controller connected to the motor's input terminals. This setup will enable real-time adjustments to the motor speed based on user requirements.

To implement this effectively, the following components are recommended:

1. **Motor Driver Circuit**: A suitable motor driver circuit should be selected that can handle the voltage and current ratings of the motor. H-bridge configurations are commonly used for bidirectional control.

2. **Speed Control Interface**: The speed control can be achieved using a potentiometer or a PWM signal generator. If using PWM, ensure that the frequency is appropriate for the motor type to prevent overheating and ensure smooth operation.

3. **Power Supply**: A stable power supply must be provided to ensure that the motor receives adequate voltage and current without fluctuations.

4. **Feedback Mechanism**: Incorporating a feedback mechanism, such as an encoder, can help in monitoring the motor speed, allowing for closed-loop control. This setup can enhance precision and responsiveness.

5. **Protection Circuitry**: It is advisable to include protection circuits such as fuses or circuit breakers to prevent damage to the motor and associated components in case of overload or short circuits.

By integrating these components into the existing wire feeder system, enhanced control over the motor speed will be achieved, leading to improved performance and versatility in its applications.I have a Chemetron wirefeeder that I am using the motor and I want to use the speed control out of the control box to control the nice motor it had in .. 🔗 External reference