servo speed tester

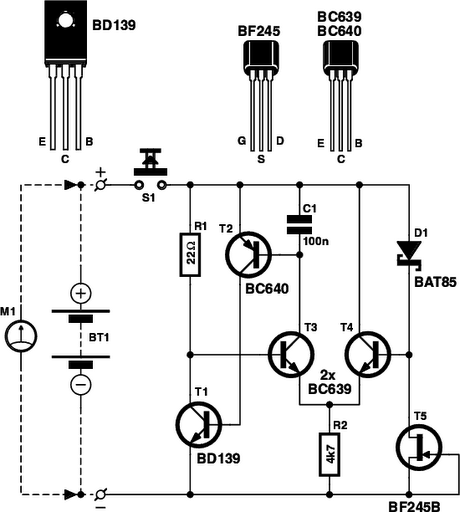

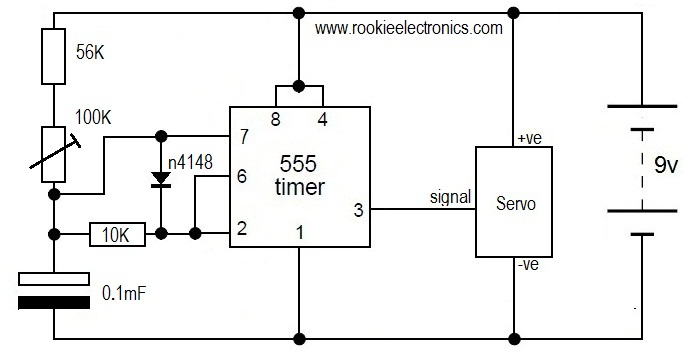

This is likely the simplest circuit to test a servo. It tests the speed of the servo using a potentiometer to control the speed. By applying a low voltage, such as 4.5V, and adjusting the potentiometer value, the position of the servo can also be modified. This circuit utilizes push switches to operate the servo in clockwise and counterclockwise directions using a 555 timer.

The described circuit functions as a basic servo motor tester, primarily aimed at evaluating the operational speed and position of a servo motor. The circuit employs a 555 timer configured in astable mode, generating a pulse-width modulation (PWM) signal that controls the servo's movement.

Key components include a potentiometer, which serves as a variable resistor, allowing for fine adjustments to the voltage supplied to the servo. By varying the resistance, the effective voltage and current reaching the servo can be altered, thus controlling the speed at which the servo rotates. The use of a 4.5V power supply is suitable for most standard servos, ensuring safe operation without exceeding the motor's voltage ratings.

Additionally, the circuit incorporates two push buttons that facilitate manual control over the servo's direction. One button is designated for clockwise rotation, while the other is for counterclockwise rotation. When pressed, these buttons send a signal to the 555 timer, which then adjusts the duty cycle of the PWM signal, effectively changing the rotation direction of the servo.

This simple yet effective circuit serves as an educational tool for understanding servo mechanics, PWM control, and the operation of the 555 timer in practical applications. It is suitable for hobbyists and beginners in electronics, providing hands-on experience with servo motors and basic circuit design.This is probably the simplest Circuit to test a Servo, This circuit tests the speed of servo. Here we use potentiometer to controll the speed of the servo. By applying very less voltage like 4. 5V and reducing the pot value, you can also adjust the position of the servo! Check this Circuit which uses push switches to run a servo in Clock-wise and a nti Clock-wise directions using 555 timer 🔗 External reference

The described circuit functions as a basic servo motor tester, primarily aimed at evaluating the operational speed and position of a servo motor. The circuit employs a 555 timer configured in astable mode, generating a pulse-width modulation (PWM) signal that controls the servo's movement.

Key components include a potentiometer, which serves as a variable resistor, allowing for fine adjustments to the voltage supplied to the servo. By varying the resistance, the effective voltage and current reaching the servo can be altered, thus controlling the speed at which the servo rotates. The use of a 4.5V power supply is suitable for most standard servos, ensuring safe operation without exceeding the motor's voltage ratings.

Additionally, the circuit incorporates two push buttons that facilitate manual control over the servo's direction. One button is designated for clockwise rotation, while the other is for counterclockwise rotation. When pressed, these buttons send a signal to the 555 timer, which then adjusts the duty cycle of the PWM signal, effectively changing the rotation direction of the servo.

This simple yet effective circuit serves as an educational tool for understanding servo mechanics, PWM control, and the operation of the 555 timer in practical applications. It is suitable for hobbyists and beginners in electronics, providing hands-on experience with servo motors and basic circuit design.This is probably the simplest Circuit to test a Servo, This circuit tests the speed of servo. Here we use potentiometer to controll the speed of the servo. By applying very less voltage like 4. 5V and reducing the pot value, you can also adjust the position of the servo! Check this Circuit which uses push switches to run a servo in Clock-wise and a nti Clock-wise directions using 555 timer 🔗 External reference