Simple bike computer tutorial

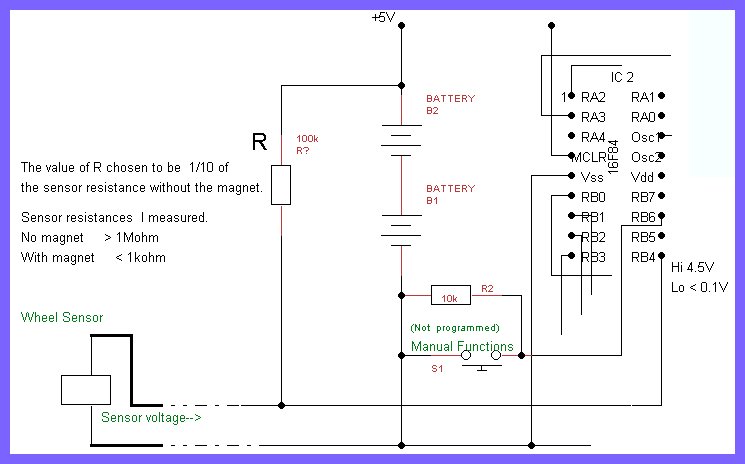

The printed circuit board (PCB) designed is large and provides ample space for modifications and additional components. However, to achieve the goal of integrating it into a real bicycle, its size presents challenges. Earlier discussions highlighted the importance of utilizing a Hall effect sensor. Currently, there is a need to acquire this sensor physically. It is noted that purchasing a standalone potted sensor with a cable is nearly impossible, as these usually come bundled with bike computers. One option is to buy a complete bike computer kit and discard or retain the computer for future use. The results observed align with the expected behavior of the sensor, showing a measurable resistance change when a magnet is brought close to it. Testing was conducted using a multimeter set to the milliampere (mA) scale across the sensor wire connected to the handlebar mount. Initially, a reading of zero mA was recorded. Upon introducing a small kitchen magnet very close to the sensor, a reading of approximately 50 microamperes (µA) was achieved. This suggests the sensor operates as a coil sensor. If it were a Hall effect device, no current change would occur when the magnet was passed over it, necessitating pulse output conditioning. This would typically involve a limiting amplifier to ensure adequate signal detection by a microcontroller, particularly at low speeds. Testing the Hall effect sensor's functionality can be performed using a voltmeter set to the ohms range, which typically provides the necessary voltage. The historical anecdote illustrates the unexpected discovery of voltage generation when a magnet interacts with a conductive material. The behavior of the Hall sensor was observed, indicating a change in resistance from megohms to kiloohms when a magnet was passed over it. Proper testing requires selecting the ohms function on the multimeter, with caution regarding battery polarity and circuit protection. A theoretical circuit includes a 100k ohm resistor between a 5V battery and the sensor, ensuring that even in the event of a short circuit, the current remains limited to 50µA, thus protecting both the sensor and the battery in the bike computer.

The PCB design serves as a critical platform for integrating various electronic components necessary for the bicycle's operation. The inclusion of a Hall effect sensor is essential for detecting the wheel's rotation, which is fundamental for speed measurement and distance calculation. The sensor's placement must ensure optimal interaction with a magnet attached to the wheel or another moving part of the bicycle.

Incorporating a Hall effect sensor into the circuit requires careful consideration of the power supply and signal conditioning. The sensor typically operates on a low voltage, often around 5V, and the output can be interfaced with a microcontroller or other processing unit. The output signal from the Hall sensor is a digital pulse that corresponds to the presence or absence of the magnetic field, allowing for accurate speed calculations.

To ensure proper functionality, the circuit should include a pull-up resistor connected to the output of the Hall sensor. This resistor helps to stabilize the signal and prevent floating states, which can lead to erroneous readings. The choice of resistor value is crucial; a common value is around 10k ohms, but this may vary based on the specific requirements of the application.

Testing the sensor's operation can be performed using a multimeter, as previously described. The resistance readings when a magnet is brought close to the sensor should show a significant drop, confirming the sensor's operational integrity. Additionally, it is advisable to verify the sensor's response at various distances and angles relative to the magnet to ensure consistent performance.

Overall, the integration of a Hall effect sensor into the bicycle's electronic system enhances its functionality, providing real-time data essential for performance monitoring and user feedback. Proper circuit design and testing are paramount to achieving reliable and accurate measurements, ultimately contributing to the overall effectiveness of the bicycle's electronic features.The PCB we have made is big and has plenty of space for cutting and adding other bits and pieces. But if we want the final satisfaction of seeing it working, mounting the lot on a real bike, it is a bit too big. Way back in chapter one, we discussed sensors and I recommended we should stay with the herd and use some sort of hall device.

Well now w e physically need one to get our hands on. I realise that it is almost impossible to buy a potted sensor +cable as a spare, they all come with a bike computer. Now we could buy a complete bike computer kit and throw the computer away. Or keep it for later as a spare. So we have results similar to the diagram. Similar means there is a measurable resistance change when the magnet is passed over and CLOSE to, he sensor body.

How can we check I connected my multimeter on the mA scale across the end of the sensor wire in the handle bar mount shoe ( place where it enters the computer). The reading is of course zero mA. Next I took one of those little kitchen fridge magnets and waved it very close ( 1mm) to the Unknown type ” of sensor.

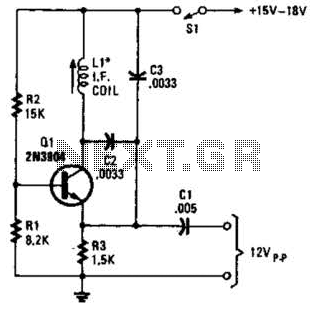

I had to find the best direction to move the magnet over the sensor, but eventually I got a reading of a about 50 uA Well I cheated as I knew it was a coil sensor, but if it hadn`t been a coil sensor, instead some sort of HALL device, then we would have no change at all when the magnet was passed across the sensor body. In that case we would need to condition the pulse output. For those interested, basically a limiting amplifier to ensure that even at the slowest speeds there is enough signal for the PIC to detect at the PORTB input.

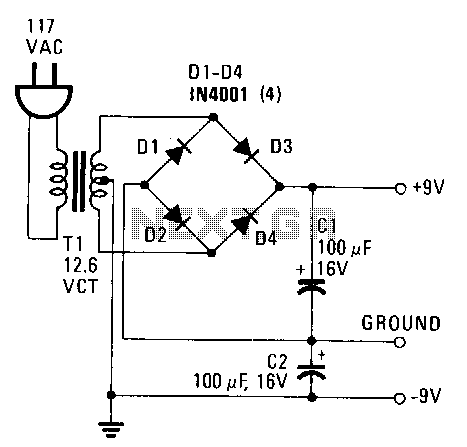

But this could be tricky, without an oscilloscope, so unless you really have set your heart on making it work, best look for a HALL device type sensor. No panic about getting a voltage supply, lets look at the following drawing on how to test a HALL type sensor.

The voltmeter on the ohms range will normally give you the required voltage-. Once upon a time a man was playing about with, frogs legs, batteries etc, passing current through his solid iron (apparently Aluminium was too expensive in those days) breakfast tray. He simply clipped the battery across the ends and his DVM across the sides. He tried a lot of things to measure the voltage, but to no avail. However one day he was messing about with magnets trying to lift the iron tray when he noticed that the voltmeter which had been left by accident from the previous session, was reading a voltage!

He jumped up and shouted Eureka, ( was that someone else ), I will call this the quantum charge displacement effect. However the cleaning lady was becoming frustrated as all this was stopping her getting on with things The drawing shows what happens as we pass the magnet across a HALL sensor.

In my case I had one that gave a change of reading from megohms to kiloohms. A range of 1000 to 1. So let`s test yours. Don`t forget to select the OHMS function on your meter. The range is adjusted for best results. This depends on the device you have found/bought. Caution. The battery here is inside the DVM, and is current limited. The hall device doesn`t care really which way you apply the battery vpltage but the amplifiers and circuits for conditioning do. Other sensors will read with the DVM ( as battery) both ways ( depends on the internal circuitry). Here the correct battery polarity is when there the reading with magnet is much larger than the reading without.

Using the ohms reading:- away from the magnet is HIGH ohms, magnet present is LOW ohms, the reverse of the volts readings. Looking at the snippet of our theoretical circuit we have a large resistor, 100k between the 5V battery and the sensor.

Even if the sensor becomes a dead short wrong way round, the maximum current is 50uA, so this class of device is protected from. damage. Also note that the battery in the Bike computer box is also protected from external short circ 🔗 External reference

The PCB design serves as a critical platform for integrating various electronic components necessary for the bicycle's operation. The inclusion of a Hall effect sensor is essential for detecting the wheel's rotation, which is fundamental for speed measurement and distance calculation. The sensor's placement must ensure optimal interaction with a magnet attached to the wheel or another moving part of the bicycle.

Incorporating a Hall effect sensor into the circuit requires careful consideration of the power supply and signal conditioning. The sensor typically operates on a low voltage, often around 5V, and the output can be interfaced with a microcontroller or other processing unit. The output signal from the Hall sensor is a digital pulse that corresponds to the presence or absence of the magnetic field, allowing for accurate speed calculations.

To ensure proper functionality, the circuit should include a pull-up resistor connected to the output of the Hall sensor. This resistor helps to stabilize the signal and prevent floating states, which can lead to erroneous readings. The choice of resistor value is crucial; a common value is around 10k ohms, but this may vary based on the specific requirements of the application.

Testing the sensor's operation can be performed using a multimeter, as previously described. The resistance readings when a magnet is brought close to the sensor should show a significant drop, confirming the sensor's operational integrity. Additionally, it is advisable to verify the sensor's response at various distances and angles relative to the magnet to ensure consistent performance.

Overall, the integration of a Hall effect sensor into the bicycle's electronic system enhances its functionality, providing real-time data essential for performance monitoring and user feedback. Proper circuit design and testing are paramount to achieving reliable and accurate measurements, ultimately contributing to the overall effectiveness of the bicycle's electronic features.The PCB we have made is big and has plenty of space for cutting and adding other bits and pieces. But if we want the final satisfaction of seeing it working, mounting the lot on a real bike, it is a bit too big. Way back in chapter one, we discussed sensors and I recommended we should stay with the herd and use some sort of hall device.

Well now w e physically need one to get our hands on. I realise that it is almost impossible to buy a potted sensor +cable as a spare, they all come with a bike computer. Now we could buy a complete bike computer kit and throw the computer away. Or keep it for later as a spare. So we have results similar to the diagram. Similar means there is a measurable resistance change when the magnet is passed over and CLOSE to, he sensor body.

How can we check I connected my multimeter on the mA scale across the end of the sensor wire in the handle bar mount shoe ( place where it enters the computer). The reading is of course zero mA. Next I took one of those little kitchen fridge magnets and waved it very close ( 1mm) to the Unknown type ” of sensor.

I had to find the best direction to move the magnet over the sensor, but eventually I got a reading of a about 50 uA Well I cheated as I knew it was a coil sensor, but if it hadn`t been a coil sensor, instead some sort of HALL device, then we would have no change at all when the magnet was passed across the sensor body. In that case we would need to condition the pulse output. For those interested, basically a limiting amplifier to ensure that even at the slowest speeds there is enough signal for the PIC to detect at the PORTB input.

But this could be tricky, without an oscilloscope, so unless you really have set your heart on making it work, best look for a HALL device type sensor. No panic about getting a voltage supply, lets look at the following drawing on how to test a HALL type sensor.

The voltmeter on the ohms range will normally give you the required voltage-. Once upon a time a man was playing about with, frogs legs, batteries etc, passing current through his solid iron (apparently Aluminium was too expensive in those days) breakfast tray. He simply clipped the battery across the ends and his DVM across the sides. He tried a lot of things to measure the voltage, but to no avail. However one day he was messing about with magnets trying to lift the iron tray when he noticed that the voltmeter which had been left by accident from the previous session, was reading a voltage!

He jumped up and shouted Eureka, ( was that someone else ), I will call this the quantum charge displacement effect. However the cleaning lady was becoming frustrated as all this was stopping her getting on with things The drawing shows what happens as we pass the magnet across a HALL sensor.

In my case I had one that gave a change of reading from megohms to kiloohms. A range of 1000 to 1. So let`s test yours. Don`t forget to select the OHMS function on your meter. The range is adjusted for best results. This depends on the device you have found/bought. Caution. The battery here is inside the DVM, and is current limited. The hall device doesn`t care really which way you apply the battery vpltage but the amplifiers and circuits for conditioning do. Other sensors will read with the DVM ( as battery) both ways ( depends on the internal circuitry). Here the correct battery polarity is when there the reading with magnet is much larger than the reading without.

Using the ohms reading:- away from the magnet is HIGH ohms, magnet present is LOW ohms, the reverse of the volts readings. Looking at the snippet of our theoretical circuit we have a large resistor, 100k between the 5V battery and the sensor.

Even if the sensor becomes a dead short wrong way round, the maximum current is 50uA, so this class of device is protected from. damage. Also note that the battery in the Bike computer box is also protected from external short circ 🔗 External reference