Small Vacuum Tube Tesla Coil 2

This tube Tesla coil was constructed within a CPU power supply unit. Initially, it was assembled on a workbench using various components and jumpers for connections. The tube utilized is a 4X150 transmitting tube that employs forced air cooling. An old oscilloscope transformer was incorporated for the power supply, delivering approximately 1 kV for high voltage and 6.3 VAC for the filament supply. The design notably lacks capacitors.

The tube Tesla coil design integrates a 4X150 transmitting tube, which is known for its robustness and ability to handle high voltages. The forced air cooling mechanism is crucial for maintaining optimal operating temperatures, thereby preventing overheating during prolonged use. The choice of the oscilloscope transformer as the power supply is significant; it not only provides the necessary high voltage but also ensures a stable and reliable source of power. The 1 kV output is essential for achieving the desired electrical discharge characteristics typical of Tesla coils, while the 6.3 VAC supply is necessary for the tube's filament, ensuring it operates efficiently.

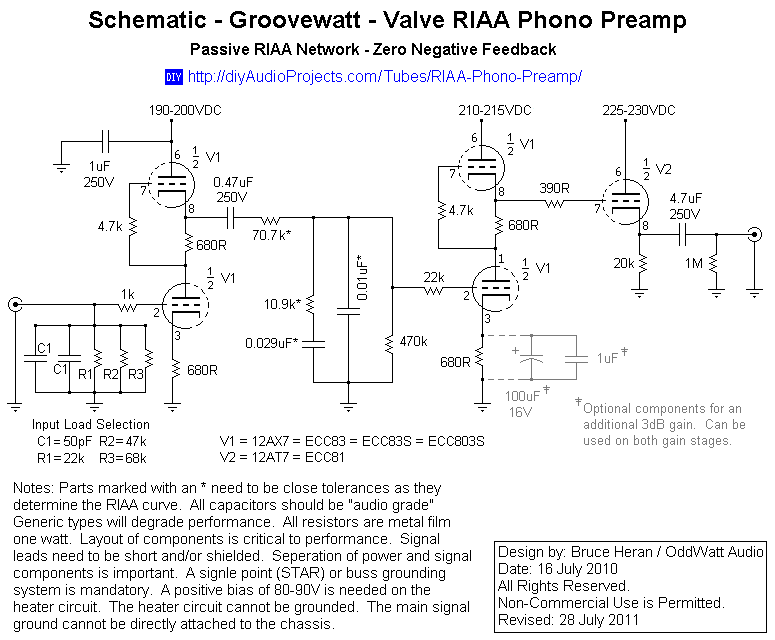

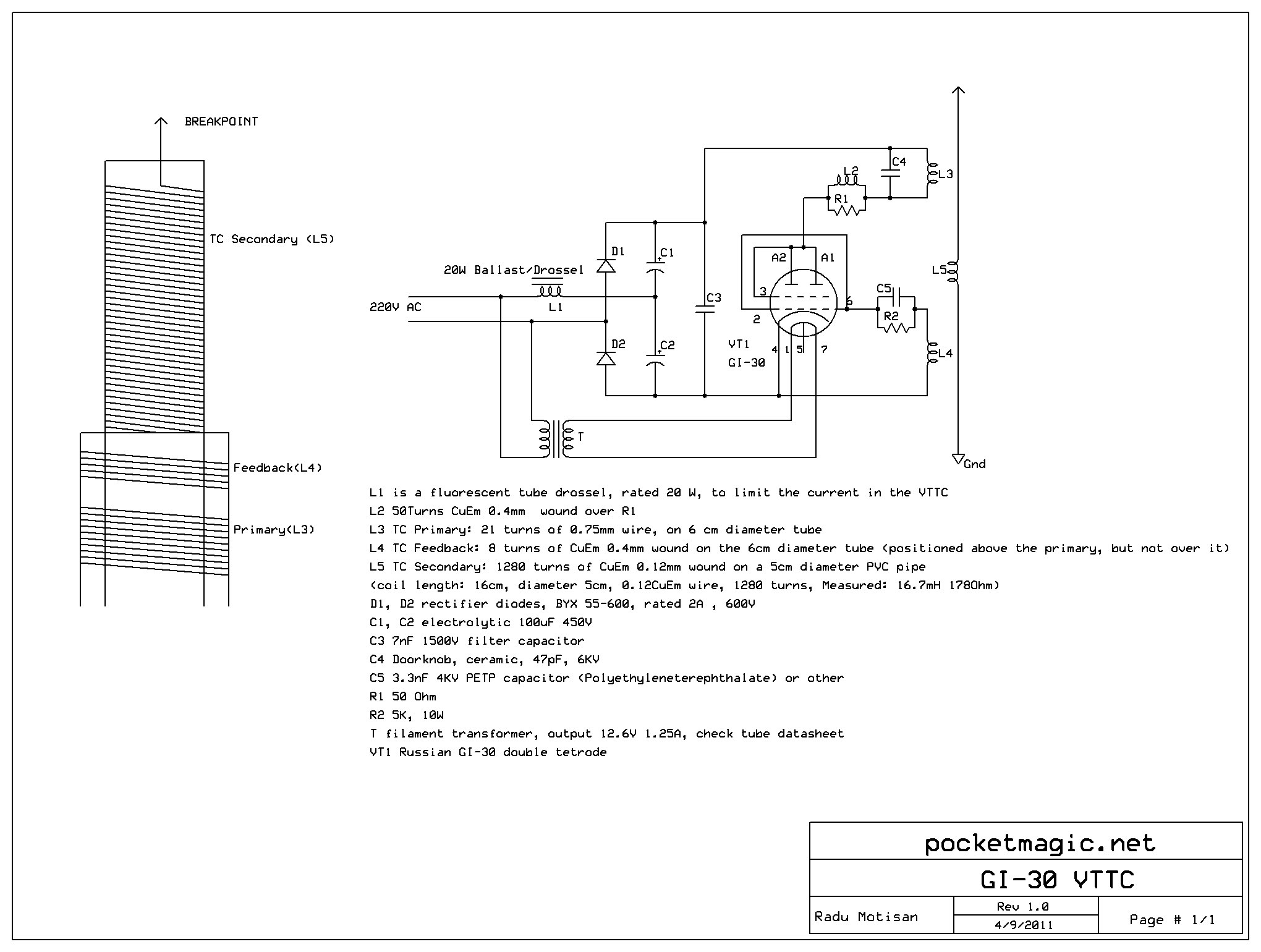

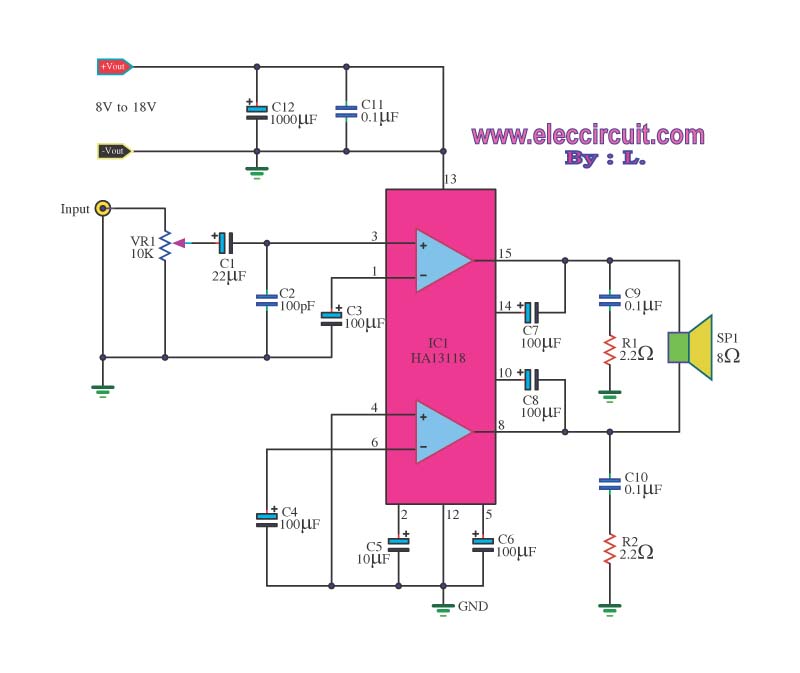

The absence of capacitors in this design is unconventional, as capacitors typically play a critical role in energy storage and discharge in traditional Tesla coil circuits. This unique approach may lead to different operational characteristics, potentially resulting in a more straightforward circuit with fewer components, thereby enhancing reliability and reducing the likelihood of component failure. The schematic diagram accompanying this description would illustrate the circuit layout, highlighting the connections between the tube, transformer, and other components, providing a visual representation of this innovative design.

This configuration may appeal to enthusiasts and engineers interested in experimenting with alternative Tesla coil designs, offering opportunities for further exploration and modification in high-voltage applications.This tube tesla coil was built inside a CPU power supply unit. It was first built on a workbench using components and jumpers for connections. The tube used is a 4X150 transmitting tube that used forced air cooling. An old oscilloscope transformer was used for the power supply, providing about 1kV for high voltage and 6. 3VAC for the filament suppl y. I experimented and played around with the circuit and came to this strange design that has no capacitors. Below is the schematic diagram. 🔗 External reference

The tube Tesla coil design integrates a 4X150 transmitting tube, which is known for its robustness and ability to handle high voltages. The forced air cooling mechanism is crucial for maintaining optimal operating temperatures, thereby preventing overheating during prolonged use. The choice of the oscilloscope transformer as the power supply is significant; it not only provides the necessary high voltage but also ensures a stable and reliable source of power. The 1 kV output is essential for achieving the desired electrical discharge characteristics typical of Tesla coils, while the 6.3 VAC supply is necessary for the tube's filament, ensuring it operates efficiently.

The absence of capacitors in this design is unconventional, as capacitors typically play a critical role in energy storage and discharge in traditional Tesla coil circuits. This unique approach may lead to different operational characteristics, potentially resulting in a more straightforward circuit with fewer components, thereby enhancing reliability and reducing the likelihood of component failure. The schematic diagram accompanying this description would illustrate the circuit layout, highlighting the connections between the tube, transformer, and other components, providing a visual representation of this innovative design.

This configuration may appeal to enthusiasts and engineers interested in experimenting with alternative Tesla coil designs, offering opportunities for further exploration and modification in high-voltage applications.This tube tesla coil was built inside a CPU power supply unit. It was first built on a workbench using components and jumpers for connections. The tube used is a 4X150 transmitting tube that used forced air cooling. An old oscilloscope transformer was used for the power supply, providing about 1kV for high voltage and 6. 3VAC for the filament suppl y. I experimented and played around with the circuit and came to this strange design that has no capacitors. Below is the schematic diagram. 🔗 External reference