stepper motor control

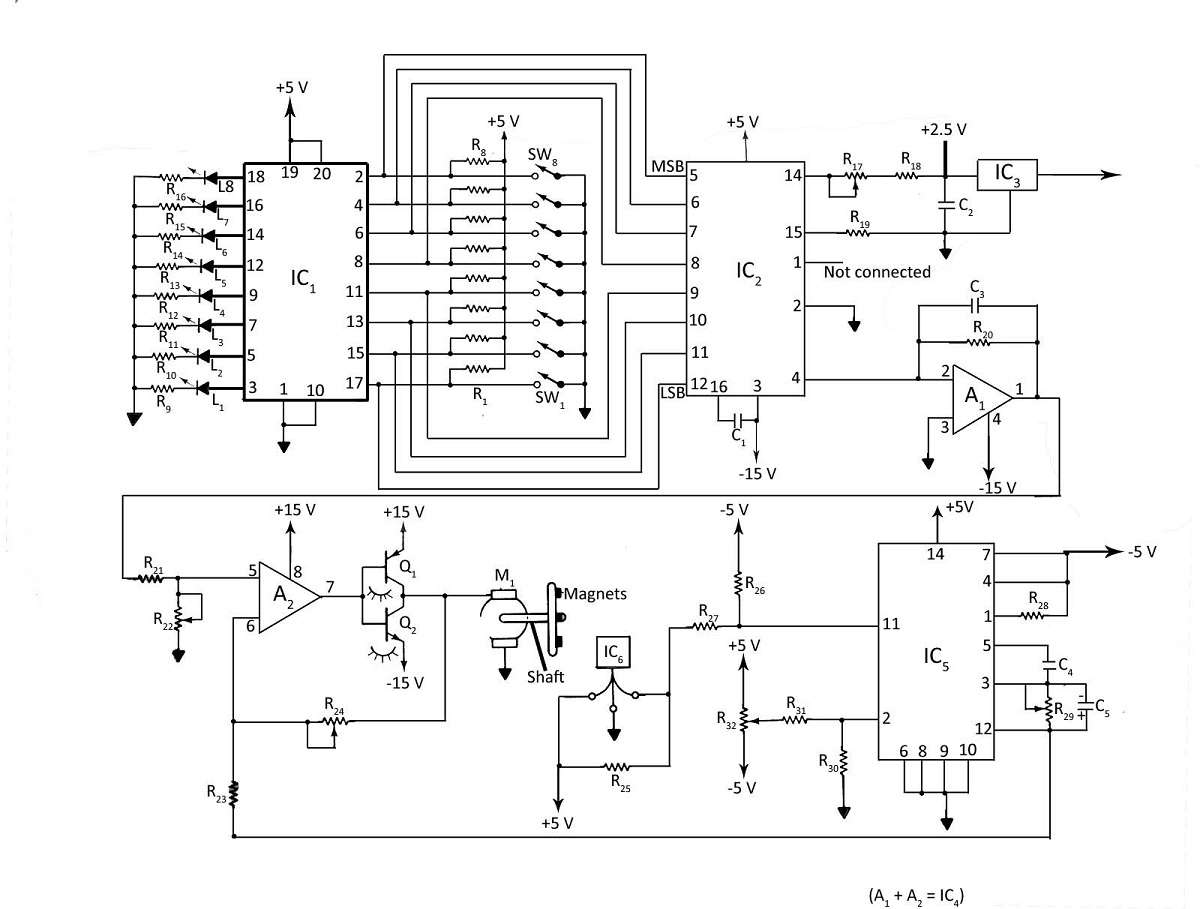

The 3D printer necessitates independent control for three separate axes. Each controlled axis must be equipped with a high-precision electronic driver. The mechanical components of each axis utilize a precise bipolar stepper motor connected to a drive shaft via a claw coupling. Additionally, a separate driver and mechanical setup are employed for the extruder. The stepper motor control is managed by a TI DRV8818, which is an enhanced version of the TI DRV8811. The primary distinction between these two devices lies in the ON-resistance value of the DRV8818's output MOSFET. The total power dissipation (TPD) is critically influenced by the device and ON-resistance, particularly when operating motors at elevated current levels. The difference in ON-resistance between the two devices is approximately 0.6 ohms. At peak current, the TPD for the DRV8818 is 1.46 W, which is 2.37 W lower than if the DRV8811 were used. Both the DRV8811 and DRV8818 function as standalone stepper motor drivers. The integration of various functions within a single IC package reduces the processing requirements. The processor only needs to control three signals per driver, minimizing MSP430 processor pin usage, which is a critical factor in the project design. The internal step indexer logic of the DRV8818 manages the stepping sequence for the motor, further alleviating the computational load on the processor. The DRV8818 features advanced current routing for motor windings through an integrated H-bridge, which decreases the number of external discrete components and enhances thermal equilibrium among the transistors. The H-bridge transistor switches are safeguarded against voltage spikes from motor winding power shutdowns by integrated fast Schottky diodes. In the schematic provided, a single stepper motor driver is illustrated. The chop (peak) current is set by the trimmer R18 in series with resistors R19 and R110. The chop current (ICHOP) is calculated using the formula ICHOP = VREF / (8RSENSE). Here, the minimum voltage VREF is 0.17 V, and the maximum voltage VREF is 1.59 V, resulting in minimum and maximum chop currents of 0.21 A and 1.99 A, respectively. The current sensing resistors R11 and R12 each have a resistance of 0.1 ohms. The driver activation is managed by the ACTIVE signal, which allows the processor to deactivate the output stage of the DRV8818. During the interval between motor steps, the output stage remains inactive. When the ACTIVE signal is low, all device functions are suspended, placing the device in a low power state. Motor stepping is controlled by the rising edge of impulses on the STEP terminal, with a maximum stepping frequency of 500 kHz as specified in the device datasheet. The wake-up time is the duration required for the device to fully activate after the ACTIVE terminal signal transitions from low to high, preventing the loss of step impulses or other irregularities. The DIRECTION terminal signal determines the stepper motor's rotation direction, which is chosen based on the terminal voltage level. The DRV8818 supports two current decay modes, with fast decay mode selected for this project by grounding the DECAY terminal. The full step indexing mode is activated by grounding the USM0 and USM1 terminals.

The described circuit operates with a focus on efficiency and precision in controlling the stepper motors necessary for 3D printing applications. The use of the TI DRV8818 driver allows for advanced control features such as current decay modes and integrated H-bridge functionality, which enhances the overall performance and reliability of the stepper motor operation. The design minimizes the load on the processor through integrated functions and simplified control signals, making it suitable for applications requiring compact and efficient electronic designs. The choice of components and their configurations, including the chop current settings and the management of active and inactive states, are critical for maintaining the desired motor performance while ensuring energy efficiency. The implementation of current sensing resistors and the ability to set the chop current through external components provides flexibility in tuning the motor characteristics for various printing requirements. Overall, this circuit design exemplifies a sophisticated approach to managing stepper motor control within a 3D printing system, emphasizing precision, efficiency, and ease of integration.The 3D printer requires separate control for three independent axis. Each of the controlled axis must have a high precision electronic driver. Mechanical part of the each axis is based on a precise bipolar stepper motor connected to a drive shaft via claw coupling. An additional driver and mechanics are used for the extruder. The stepper motor con trol is based on a TI DRV8818. The DRV8818 is an improved version of the TI DRV8811. Main difference between these two devices is in the value of the ON-resistance of the DRV8818 output MOSFET. A direct dependence of total power dissipation (TPD) over the device and ON-resistance is a critical parameter when running motors at higher levels of currents.

Roughly calculated, difference of the ON-resistance between the two before mentioned devices is 0. 6 ©. At the peak current value, TPD of the DRV8818 is 1. 46 W and is lower by 2. 37 W then it would be if the DRV8811 was selected. Both DRV8811 and DRV8818 are fully functional stand alone stepper motor drivers. The integration of various functions in single IC package decreases the requirements on the processor unit. The processor unit controls only three signals per driver. This allows minimal MSP430 processor pin usage per driver device and that was one of the important parameters for a project design.

Furthermore, the stepping sequence for the motor is realized by the DRV8818 internal step indexer logic which also reduces the computational burden on the processor unit. The DRV8818 supports advanced current routing for motor windings realized by an integrated H-bridge. Integration of the H-bridge inside the DRV8818 package reduce the number of external discrete elements and improves matching and thermal equilibrium between the transistors.

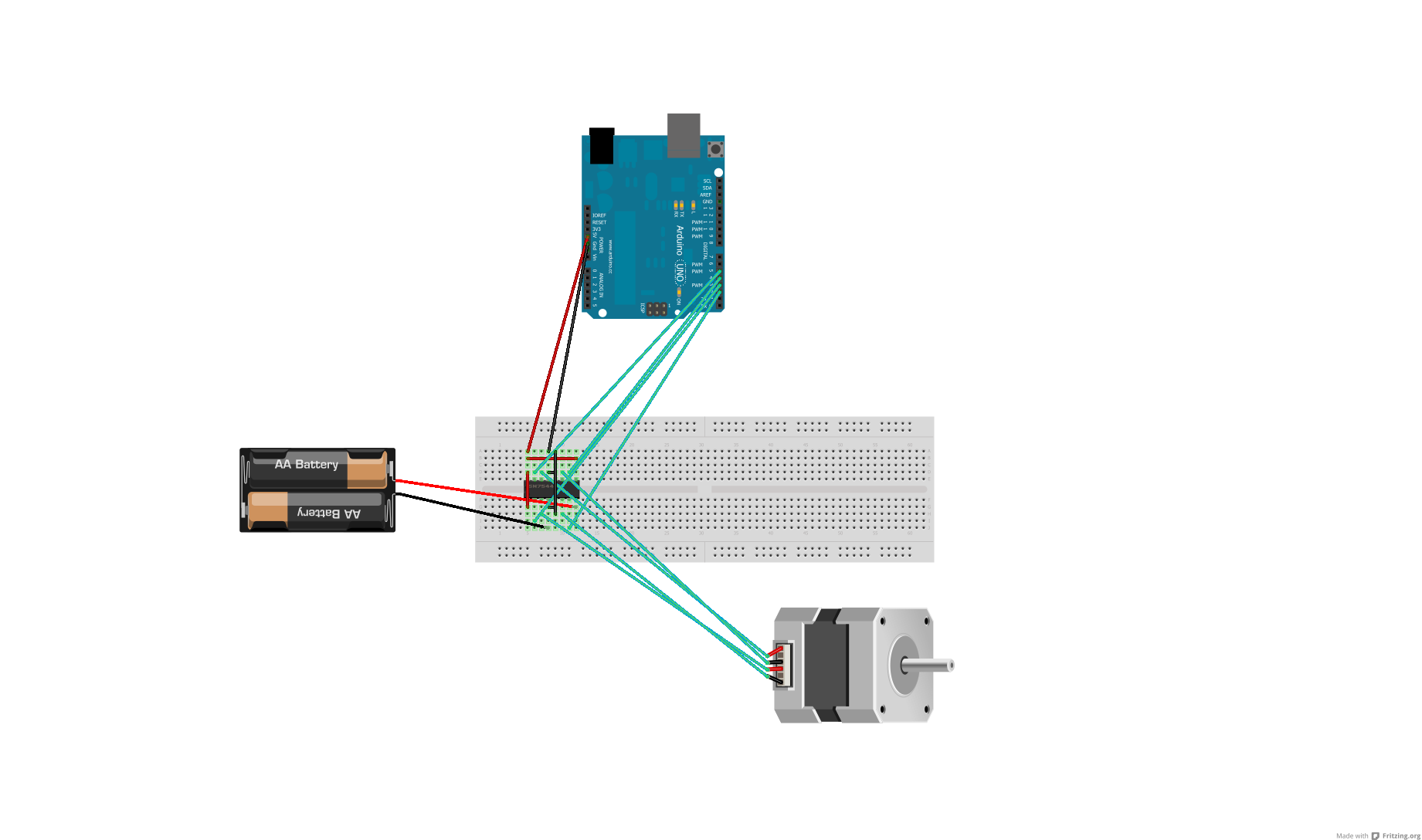

The transistor switches used in the H-bridge are protected from the voltage spikes caused by turning the power off in a motor winding by the integrated fast schottky diodes. In chematic presented below the single stepper motor driver is presented. The chop (peak) current is defined by the trimmer R18 connected in series with the resistors R19 and R110.

The ICHOP is calculated by an expression ICHOP = VREF / (8RSENSE). In this case, the voltage VREF, min is 0. 17 V, and the voltage VREF, max is 1. 59 V. The minimum and maximum values of the voltage VREF define the currents ICHOP, min at 0. 21 A, and ICHOP, max at 1. 99 A. The current sensing resistors R11 and R12 have resistance of 0. 1 ©. The activation of the driver is controlled by ACTIVE signal. The ACTIVE signal allows the processor to shut off the output stage of the DRV8818. During the period between two steps of the motor, the output stage is inactive. When the ACTIVE signal is low, all functions of the device are suspended and the device is in a low power state. Stepping of the motor is controlled with the rising edge of the impulses on the STEP terminal. The maximum stepping frequency of 500 kHz is defined by the device data sheet. The wake-up time is the time interval needed for the device to become fully active after the signal on the ACTIVE terminal is changed from a low to high, in order to prevent loosing step impulses or other irregularities.

Selected value was experimentally confirmed as the correct choice. The signal on the DIRECTION terminal selects the clockwise or the counter clockwise rotation of the stepper motor. The direction of rotation is selected upon the terminal voltage level. The DRV8818 supports two current decay modes. In this project fast decay mode is selected. The mode selection is done by grounding the DECAY terminal. The full step indexing mode is selected by grounding terminals USM0 and USM1. 🔗 External reference

The described circuit operates with a focus on efficiency and precision in controlling the stepper motors necessary for 3D printing applications. The use of the TI DRV8818 driver allows for advanced control features such as current decay modes and integrated H-bridge functionality, which enhances the overall performance and reliability of the stepper motor operation. The design minimizes the load on the processor through integrated functions and simplified control signals, making it suitable for applications requiring compact and efficient electronic designs. The choice of components and their configurations, including the chop current settings and the management of active and inactive states, are critical for maintaining the desired motor performance while ensuring energy efficiency. The implementation of current sensing resistors and the ability to set the chop current through external components provides flexibility in tuning the motor characteristics for various printing requirements. Overall, this circuit design exemplifies a sophisticated approach to managing stepper motor control within a 3D printing system, emphasizing precision, efficiency, and ease of integration.The 3D printer requires separate control for three independent axis. Each of the controlled axis must have a high precision electronic driver. Mechanical part of the each axis is based on a precise bipolar stepper motor connected to a drive shaft via claw coupling. An additional driver and mechanics are used for the extruder. The stepper motor con trol is based on a TI DRV8818. The DRV8818 is an improved version of the TI DRV8811. Main difference between these two devices is in the value of the ON-resistance of the DRV8818 output MOSFET. A direct dependence of total power dissipation (TPD) over the device and ON-resistance is a critical parameter when running motors at higher levels of currents.

Roughly calculated, difference of the ON-resistance between the two before mentioned devices is 0. 6 ©. At the peak current value, TPD of the DRV8818 is 1. 46 W and is lower by 2. 37 W then it would be if the DRV8811 was selected. Both DRV8811 and DRV8818 are fully functional stand alone stepper motor drivers. The integration of various functions in single IC package decreases the requirements on the processor unit. The processor unit controls only three signals per driver. This allows minimal MSP430 processor pin usage per driver device and that was one of the important parameters for a project design.

Furthermore, the stepping sequence for the motor is realized by the DRV8818 internal step indexer logic which also reduces the computational burden on the processor unit. The DRV8818 supports advanced current routing for motor windings realized by an integrated H-bridge. Integration of the H-bridge inside the DRV8818 package reduce the number of external discrete elements and improves matching and thermal equilibrium between the transistors.

The transistor switches used in the H-bridge are protected from the voltage spikes caused by turning the power off in a motor winding by the integrated fast schottky diodes. In chematic presented below the single stepper motor driver is presented. The chop (peak) current is defined by the trimmer R18 connected in series with the resistors R19 and R110.

The ICHOP is calculated by an expression ICHOP = VREF / (8RSENSE). In this case, the voltage VREF, min is 0. 17 V, and the voltage VREF, max is 1. 59 V. The minimum and maximum values of the voltage VREF define the currents ICHOP, min at 0. 21 A, and ICHOP, max at 1. 99 A. The current sensing resistors R11 and R12 have resistance of 0. 1 ©. The activation of the driver is controlled by ACTIVE signal. The ACTIVE signal allows the processor to shut off the output stage of the DRV8818. During the period between two steps of the motor, the output stage is inactive. When the ACTIVE signal is low, all functions of the device are suspended and the device is in a low power state. Stepping of the motor is controlled with the rising edge of the impulses on the STEP terminal. The maximum stepping frequency of 500 kHz is defined by the device data sheet. The wake-up time is the time interval needed for the device to become fully active after the signal on the ACTIVE terminal is changed from a low to high, in order to prevent loosing step impulses or other irregularities.

Selected value was experimentally confirmed as the correct choice. The signal on the DIRECTION terminal selects the clockwise or the counter clockwise rotation of the stepper motor. The direction of rotation is selected upon the terminal voltage level. The DRV8818 supports two current decay modes. In this project fast decay mode is selected. The mode selection is done by grounding the DECAY terminal. The full step indexing mode is selected by grounding terminals USM0 and USM1. 🔗 External reference