Stepper Motor Interface to Microcontroller

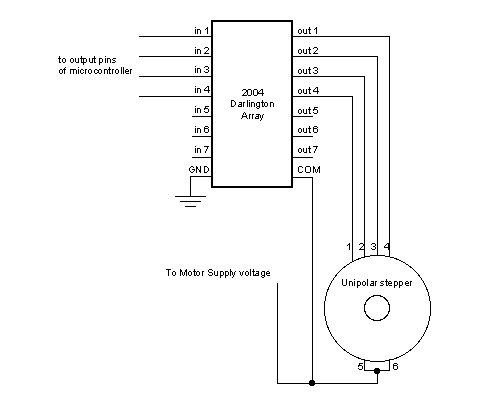

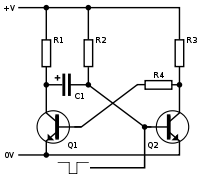

The circuit features four pins labeled "Controller pin 1," "Controller pin 2," "Controller pin 3," and "Controller pin 4," which are responsible for controlling the motion and direction of the stepper motor based on the step sequence programmed into the controller. Similar to the previously discussed L293D circuit, these four pins dictate the operation of the stepper motor according to the step sequence provided by the controller. Bipolar stepper motors are characterized by having two distinct coils, and the step sequence for bipolar stepper motors is analogous to that of unipolar stepper motors. The driving circuit requires an H-Bridge configuration, which facilitates independent control over the polarity of the power applied to the motor. This setup is illustrated in the accompanying figure. The methods for interfacing stepper motors with a microcontroller have been examined, and the next focus will be on programming the microcontroller to effectively control the stepper motors.

The described circuit utilizes an H-Bridge configuration to drive a bipolar stepper motor, allowing for precise control of the motor's motion and direction. The H-Bridge consists of four switches (typically MOSFETs or transistors) arranged in a bridge layout, enabling the application of voltage across the motor coils in both directions. This arrangement is essential for reversing the motor's direction, which is achieved by activating the appropriate controller pins in a specific sequence.

The controller pins are connected to the input terminals of the H-Bridge. When a high signal is sent to "Controller pin 1," it activates one side of the H-Bridge, allowing current to flow through one coil of the motor. Activating "Controller pin 2" simultaneously allows current to flow through the opposite coil, creating a magnetic field that causes the motor to step. The sequence of activating these pins determines the stepping pattern, which can be full-step, half-step, or micro-stepping, depending on the desired resolution and smoothness of the motor's operation.

The programming of the microcontroller involves defining the step sequence and timing for each pin activation. This can be achieved using a timer interrupt or a loop that iterates through the defined sequence, ensuring that the timing between steps is consistent with the motor's specifications. Proper timing is critical to prevent missed steps or stalling, particularly under load.

In summary, the circuit's design and the programming of the microcontroller work in tandem to achieve precise control of the bipolar stepper motor's motion. The implementation of an H-Bridge allows for versatile control of the motor's direction and speed, making it suitable for various applications in robotics, automation, and precise positioning systems.As you see in the circuit above the four pins "Controller pin 1", 2, 3 and 4 will control the motion and direction of the stepper motor according to the step sequece programmed in the controller. As already discussed in case of L293D, Here in this circuit too the four pins "Controller pin 1", 2, 3 and 4 will control the motion and direction of the ste

pper motor according to the step sequece sent by the controller. As we have studied that, Bi-polar stepper motors has 2 different coils. The step sequence for Bipolar stepper motor is same as that of unipolar stepper motors. The driving circuit for this require an H-Bridge as it allows the polarity of the power applied to be controlled independently. This can be done as shown in the figure below: Now we have seen the methods for connecting stepper motors with your microcontroller.

So keeping these circuits in mind, we will now look at the programming of microcontroller to control stepper motors. 🔗 External reference

The described circuit utilizes an H-Bridge configuration to drive a bipolar stepper motor, allowing for precise control of the motor's motion and direction. The H-Bridge consists of four switches (typically MOSFETs or transistors) arranged in a bridge layout, enabling the application of voltage across the motor coils in both directions. This arrangement is essential for reversing the motor's direction, which is achieved by activating the appropriate controller pins in a specific sequence.

The controller pins are connected to the input terminals of the H-Bridge. When a high signal is sent to "Controller pin 1," it activates one side of the H-Bridge, allowing current to flow through one coil of the motor. Activating "Controller pin 2" simultaneously allows current to flow through the opposite coil, creating a magnetic field that causes the motor to step. The sequence of activating these pins determines the stepping pattern, which can be full-step, half-step, or micro-stepping, depending on the desired resolution and smoothness of the motor's operation.

The programming of the microcontroller involves defining the step sequence and timing for each pin activation. This can be achieved using a timer interrupt or a loop that iterates through the defined sequence, ensuring that the timing between steps is consistent with the motor's specifications. Proper timing is critical to prevent missed steps or stalling, particularly under load.

In summary, the circuit's design and the programming of the microcontroller work in tandem to achieve precise control of the bipolar stepper motor's motion. The implementation of an H-Bridge allows for versatile control of the motor's direction and speed, making it suitable for various applications in robotics, automation, and precise positioning systems.As you see in the circuit above the four pins "Controller pin 1", 2, 3 and 4 will control the motion and direction of the stepper motor according to the step sequece programmed in the controller. As already discussed in case of L293D, Here in this circuit too the four pins "Controller pin 1", 2, 3 and 4 will control the motion and direction of the ste

pper motor according to the step sequece sent by the controller. As we have studied that, Bi-polar stepper motors has 2 different coils. The step sequence for Bipolar stepper motor is same as that of unipolar stepper motors. The driving circuit for this require an H-Bridge as it allows the polarity of the power applied to be controlled independently. This can be done as shown in the figure below: Now we have seen the methods for connecting stepper motors with your microcontroller.

So keeping these circuits in mind, we will now look at the programming of microcontroller to control stepper motors. 🔗 External reference