TC649 motor drive circuit with overheat protection

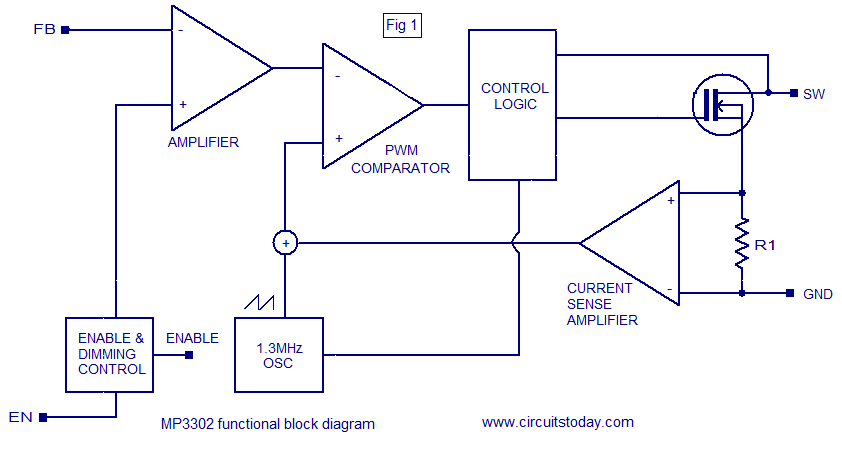

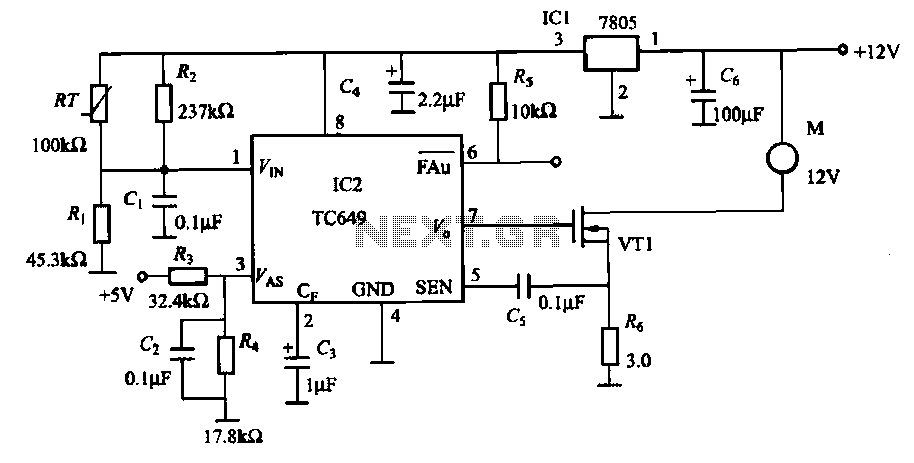

A motor is a heating device that can overheat, often due to accidents or overloads caused by excessive coil winding temperatures. The TC649 motor overheating protection and drive circuit, depicted in FIG. 1-9, utilizes an NTC thermistor (RT) positioned near the motor for temperature detection. The input voltage to the PWM control circuit (IC2) is determined by resistor R2, with a typical range of 1.2V to 2.6V. This input voltage controls the output signal's pulse width modulation duty cycle, which can vary from 0% to 100%. For instance, at 30°C, the input voltage (VIN) is 1.9V, resulting in a 50% duty cycle; at 60°C, VIN reaches 2.6V, leading to a 100% duty cycle. The PWM signal drives VT1 to adjust the motor speed. Current detection is implemented to limit the motor's current flow, with feedback from resistor R6 to ensure that the maximum output current is controlled. An automatic shutdown threshold level is established, and by appropriately selecting VT1 and the supply voltage, the circuit can effectively drive a fan motor or other larger loads.

The described circuit design incorporates several critical components to ensure effective motor temperature monitoring and control. The NTC thermistor (RT) serves as a temperature sensor, providing real-time feedback on the motor's operating temperature. As the temperature increases, the resistance of the NTC thermistor decreases, resulting in a corresponding change in the voltage input to the PWM control circuit (IC2). This relationship allows for precise control of the motor's operation based on its thermal state.

The PWM control circuit is configured to modulate the duty cycle of the output signal, which directly influences the speed of the motor. The range of input voltage from 1.2V to 2.6V enables the circuit to accommodate various operating conditions, ensuring optimal performance across different temperature thresholds. The duty cycle is adjusted based on the temperature readings, allowing for gradual increases in speed as the motor cools down and requires less power.

VT1 plays a pivotal role in the circuit by acting as a variable speed controller for the motor. The PWM signal generated by IC2 drives VT1, which regulates the voltage supplied to the motor. This allows for smooth transitions in motor speed, enhancing the overall efficiency of the system.

Current detection is critical for protecting the motor from potential damage due to excessive current draw. The inclusion of feedback through resistor R6 allows for monitoring and limiting the current flowing through the motor, ensuring that it operates within safe parameters. If the current exceeds predetermined levels, the circuit can trigger an automatic shutdown to prevent overheating and potential failure.

Overall, this motor overheating protection and drive circuit exemplifies a robust design that integrates temperature sensing, PWM control, and current limiting features, making it suitable for various applications, including fan motors and other larger loads. The careful selection of components and design strategies ensures reliable operation and enhanced safety for motor-driven devices.Motor is heating devices, by accident or overload often caused when the coil winding temperature is too high, as shown in FIG. 1-9 TC649 motor overheating protection and drive circuit. NTC thermistor RT close to the motor of the motor temperature detection, RT, James I, R2 determine the IC2 input into the PWM control voltage VIN, setting range is generally 1.2 ~ 2.6V, the output voltage control output K points (pulse width modulation duty cycle) signal (range of O ~ 100%). For example, 30C when, VIN = 1.9V, the duty cycle is 50qo; when 60qC, VIN = 2, 6V, 100% duty cycle; after changing the motor speed VT1 driven by the PWM signal.

feet for the current detection, for limiting the size of the motor current flowing through the motor or VT1 generated by the current pressure on the R6 drop by c5 feedback to feet, the maximum output current of the motor control. feet set up automatic shutdown threshold level. Suitably selected VT1 and supply voltage, the circuit can drive a fan motor or larger loads.

The described circuit design incorporates several critical components to ensure effective motor temperature monitoring and control. The NTC thermistor (RT) serves as a temperature sensor, providing real-time feedback on the motor's operating temperature. As the temperature increases, the resistance of the NTC thermistor decreases, resulting in a corresponding change in the voltage input to the PWM control circuit (IC2). This relationship allows for precise control of the motor's operation based on its thermal state.

The PWM control circuit is configured to modulate the duty cycle of the output signal, which directly influences the speed of the motor. The range of input voltage from 1.2V to 2.6V enables the circuit to accommodate various operating conditions, ensuring optimal performance across different temperature thresholds. The duty cycle is adjusted based on the temperature readings, allowing for gradual increases in speed as the motor cools down and requires less power.

VT1 plays a pivotal role in the circuit by acting as a variable speed controller for the motor. The PWM signal generated by IC2 drives VT1, which regulates the voltage supplied to the motor. This allows for smooth transitions in motor speed, enhancing the overall efficiency of the system.

Current detection is critical for protecting the motor from potential damage due to excessive current draw. The inclusion of feedback through resistor R6 allows for monitoring and limiting the current flowing through the motor, ensuring that it operates within safe parameters. If the current exceeds predetermined levels, the circuit can trigger an automatic shutdown to prevent overheating and potential failure.

Overall, this motor overheating protection and drive circuit exemplifies a robust design that integrates temperature sensing, PWM control, and current limiting features, making it suitable for various applications, including fan motors and other larger loads. The careful selection of components and design strategies ensures reliable operation and enhanced safety for motor-driven devices.Motor is heating devices, by accident or overload often caused when the coil winding temperature is too high, as shown in FIG. 1-9 TC649 motor overheating protection and drive circuit. NTC thermistor RT close to the motor of the motor temperature detection, RT, James I, R2 determine the IC2 input into the PWM control voltage VIN, setting range is generally 1.2 ~ 2.6V, the output voltage control output K points (pulse width modulation duty cycle) signal (range of O ~ 100%). For example, 30C when, VIN = 1.9V, the duty cycle is 50qo; when 60qC, VIN = 2, 6V, 100% duty cycle; after changing the motor speed VT1 driven by the PWM signal.

feet for the current detection, for limiting the size of the motor current flowing through the motor or VT1 generated by the current pressure on the R6 drop by c5 feedback to feet, the maximum output current of the motor control. feet set up automatic shutdown threshold level. Suitably selected VT1 and supply voltage, the circuit can drive a fan motor or larger loads.