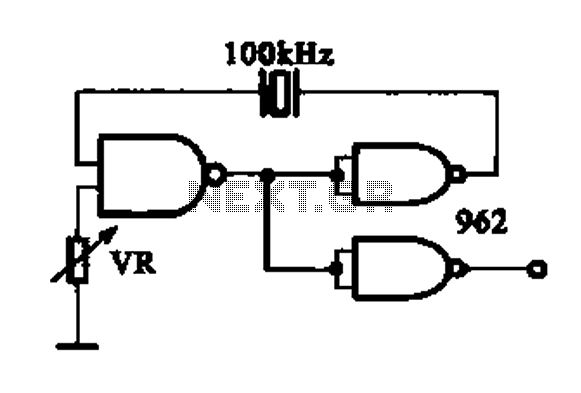

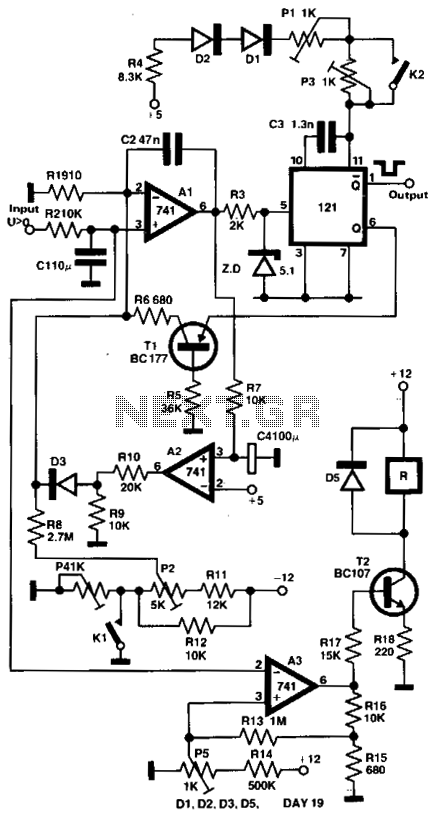

Temperature Controller for Crystal Oven

The temperature of a quartz crystal oscillator must be maintained at a constant level to ensure stable frequency operation. This oven temperature controller is appropriate for this purpose.

The operation of quartz crystal oscillators relies heavily on temperature stability, as variations in temperature can lead to frequency drift, affecting overall performance in various applications such as communication systems, clocks, and precision timing devices. To mitigate these fluctuations, an oven temperature controller is employed to maintain the quartz crystal at a predetermined temperature, typically above ambient levels.

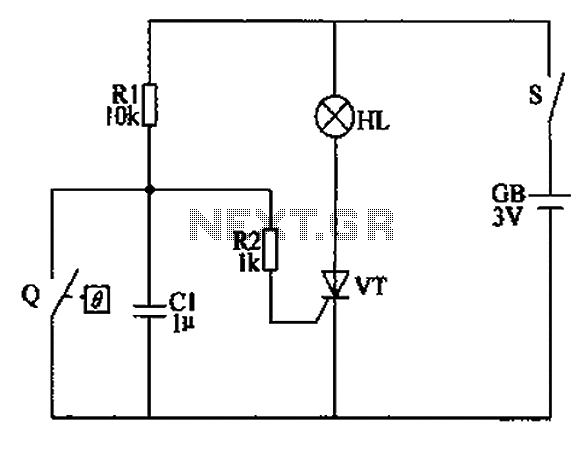

The oven temperature controller integrates several key components: a temperature sensor (such as a thermistor or thermocouple) to monitor the current temperature of the crystal, a microcontroller or dedicated control circuit to process the temperature data, and a heating element (such as a resistive heater) to adjust the temperature as needed.

The control algorithm typically used in these systems can be a PID (Proportional-Integral-Derivative) controller, which continuously calculates an error value as the difference between a desired setpoint and a measured process variable (the current temperature). The PID controller adjusts the heating element's power output to minimize this error, thereby stabilizing the temperature of the quartz crystal.

In addition to the basic control elements, the oven temperature controller may also include features such as temperature logging, user interface for setting temperature parameters, and safety mechanisms to prevent overheating. The design must ensure that the heating element is adequately insulated to prevent heat loss and that the temperature sensor is positioned correctly to provide accurate readings of the crystal's temperature.

Overall, the implementation of an oven temperature controller is crucial for applications requiring high-frequency stability and precision, allowing quartz crystal oscillators to perform optimally under varying environmental conditions.The temperature of a quartz crystal for oscillator should to be kept constant to operate at very stable frequency. This oven temperature controller is suitable. 🔗 External reference

The operation of quartz crystal oscillators relies heavily on temperature stability, as variations in temperature can lead to frequency drift, affecting overall performance in various applications such as communication systems, clocks, and precision timing devices. To mitigate these fluctuations, an oven temperature controller is employed to maintain the quartz crystal at a predetermined temperature, typically above ambient levels.

The oven temperature controller integrates several key components: a temperature sensor (such as a thermistor or thermocouple) to monitor the current temperature of the crystal, a microcontroller or dedicated control circuit to process the temperature data, and a heating element (such as a resistive heater) to adjust the temperature as needed.

The control algorithm typically used in these systems can be a PID (Proportional-Integral-Derivative) controller, which continuously calculates an error value as the difference between a desired setpoint and a measured process variable (the current temperature). The PID controller adjusts the heating element's power output to minimize this error, thereby stabilizing the temperature of the quartz crystal.

In addition to the basic control elements, the oven temperature controller may also include features such as temperature logging, user interface for setting temperature parameters, and safety mechanisms to prevent overheating. The design must ensure that the heating element is adequately insulated to prevent heat loss and that the temperature sensor is positioned correctly to provide accurate readings of the crystal's temperature.

Overall, the implementation of an oven temperature controller is crucial for applications requiring high-frequency stability and precision, allowing quartz crystal oscillators to perform optimally under varying environmental conditions.The temperature of a quartz crystal for oscillator should to be kept constant to operate at very stable frequency. This oven temperature controller is suitable. 🔗 External reference