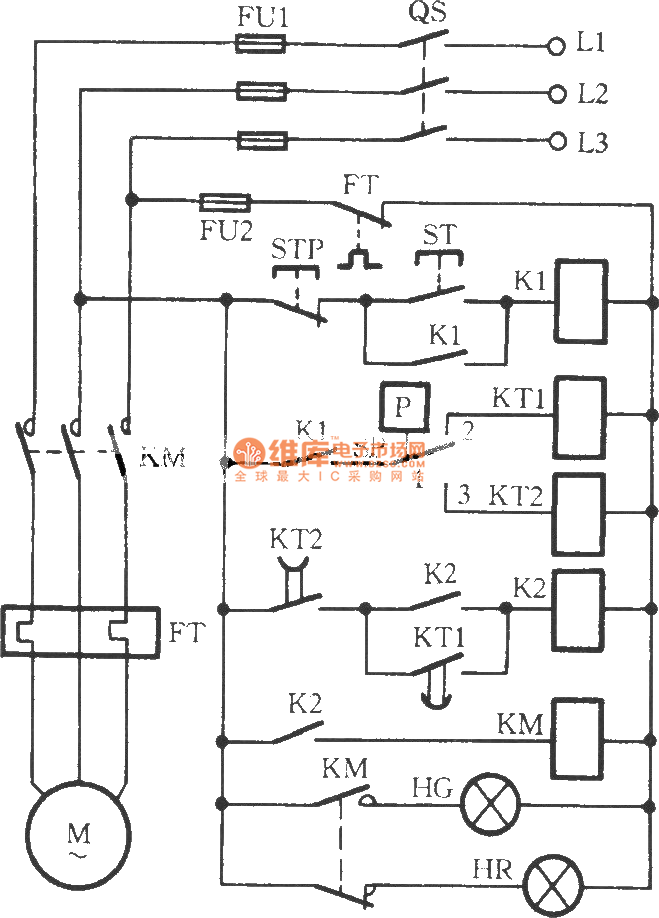

The series connecting control circuit of electric contact pressure gauge and time relay

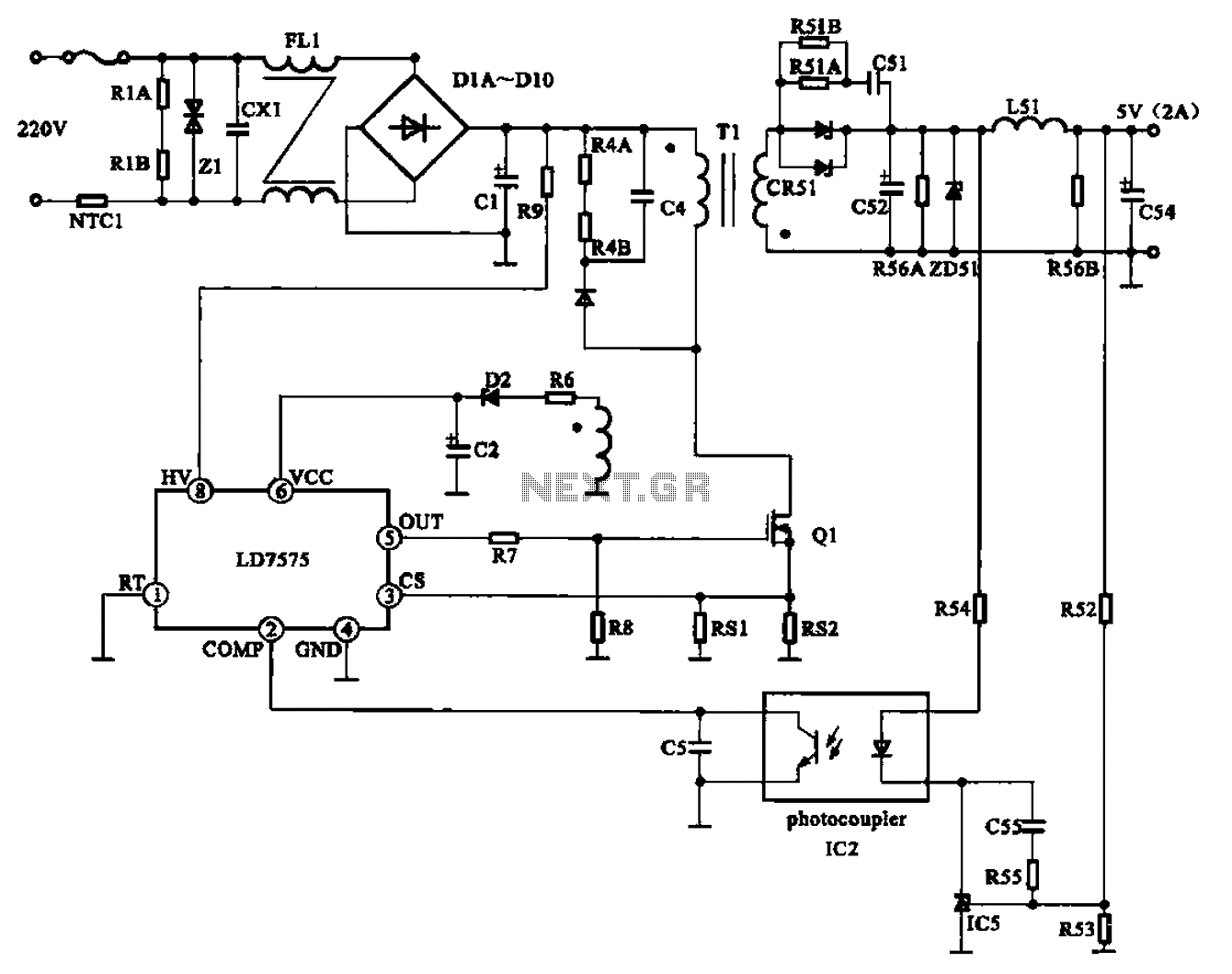

The circuit utilizes two time relays, KT1 and KT2, which are connected in series with the contacts of an electric contact pressure gauge (SP). This configuration helps to mitigate issues such as tremors or sparking that may occur due to the incomplete separation and contact of the SP during the motor's automatic start or stop phase, particularly when liquid or gas pressure has not yet been reached.

The circuit design features two time relays, KT1 and KT2, which play a crucial role in managing the operational timing of the electric contact pressure gauge (SP). The relays are strategically connected in series with the gauge to ensure that the system operates smoothly without the risk of electrical arcing or mechanical wear caused by premature contact.

When the system is activated, the time relays introduce a delay before the gauge contacts close, allowing sufficient time for the pressure to stabilize. This delay is essential to prevent the gauge from reacting to transient pressures that could occur during the motor's start-up or shutdown phases. The relays are selected based on their time delay characteristics to match the specific requirements of the application, ensuring that the pressure readings are accurate and reliable.

The relay contacts are designed to handle the electrical load of the motor control circuit, providing a safe interface between the pressure gauge and the motor's control system. The series connection ensures that both relays must be activated for the circuit to complete, adding an additional layer of safety and redundancy.

Furthermore, the circuit may include protective features such as fuses or circuit breakers to safeguard against overload conditions. Proper grounding and shielding techniques should also be implemented to minimize electromagnetic interference and enhance the overall reliability of the system.

Overall, the integration of time relays with an electric contact pressure gauge in this circuit design significantly improves the operational stability and safety of the motor control system, particularly in applications where pressure fluctuations are common.As shown in Figure, the circuit usestwo time relays KT1, KT2 to connect with thecontactsofelectric contact pressure gauge SP in series. When liquid or gas pressure has not yet reached, it can overcome thetrembling or spark phenomenons because of the SP`s incomplete separating andtoucing in the crash time of motor automatic start or stop,and itimprovesthe re..

🔗 External reference

The circuit design features two time relays, KT1 and KT2, which play a crucial role in managing the operational timing of the electric contact pressure gauge (SP). The relays are strategically connected in series with the gauge to ensure that the system operates smoothly without the risk of electrical arcing or mechanical wear caused by premature contact.

When the system is activated, the time relays introduce a delay before the gauge contacts close, allowing sufficient time for the pressure to stabilize. This delay is essential to prevent the gauge from reacting to transient pressures that could occur during the motor's start-up or shutdown phases. The relays are selected based on their time delay characteristics to match the specific requirements of the application, ensuring that the pressure readings are accurate and reliable.

The relay contacts are designed to handle the electrical load of the motor control circuit, providing a safe interface between the pressure gauge and the motor's control system. The series connection ensures that both relays must be activated for the circuit to complete, adding an additional layer of safety and redundancy.

Furthermore, the circuit may include protective features such as fuses or circuit breakers to safeguard against overload conditions. Proper grounding and shielding techniques should also be implemented to minimize electromagnetic interference and enhance the overall reliability of the system.

Overall, the integration of time relays with an electric contact pressure gauge in this circuit design significantly improves the operational stability and safety of the motor control system, particularly in applications where pressure fluctuations are common.As shown in Figure, the circuit usestwo time relays KT1, KT2 to connect with thecontactsofelectric contact pressure gauge SP in series. When liquid or gas pressure has not yet reached, it can overcome thetrembling or spark phenomenons because of the SP`s incomplete separating andtoucing in the crash time of motor automatic start or stop,and itimprovesthe re..

🔗 External reference