Three reverse brake circuits to operate energy

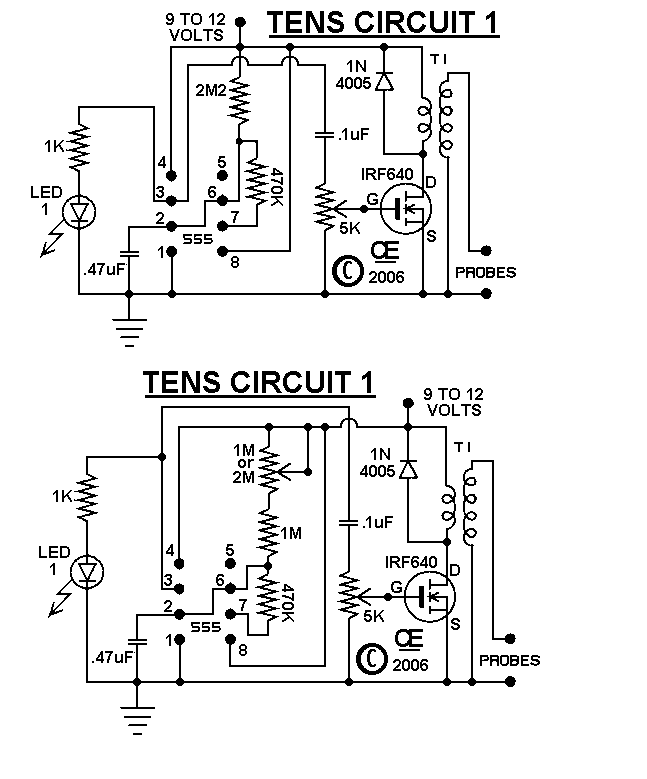

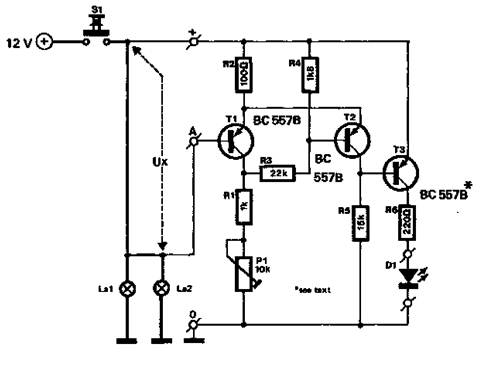

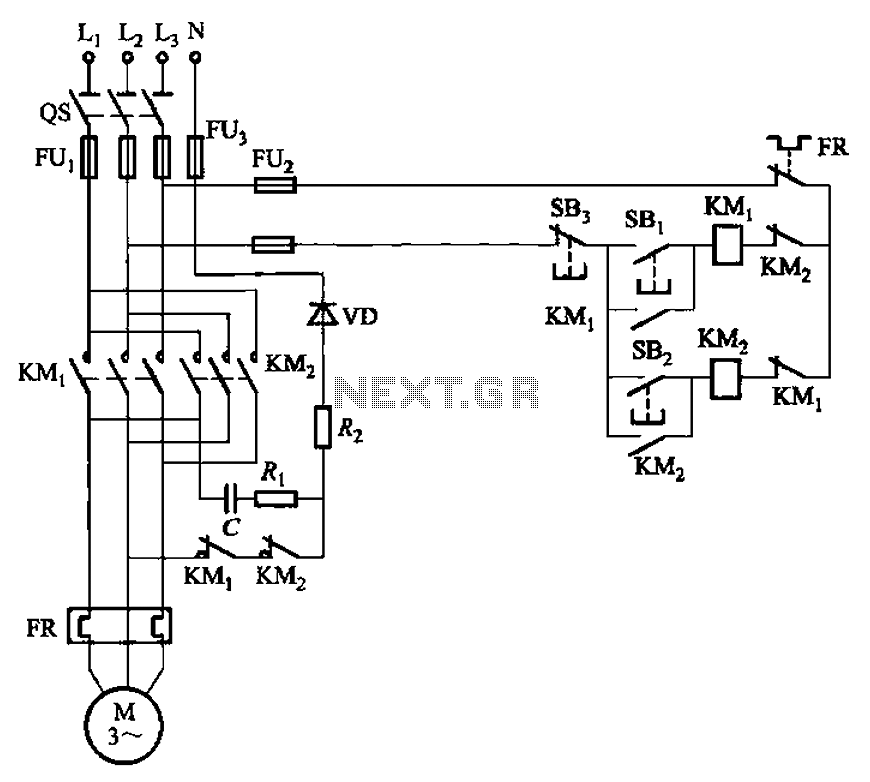

The circuit depicted in Figure 3-146 eliminates the need for a step-down transformer by utilizing the principle of energy storage through capacitor discharge for braking. It can be employed to frequently start and stop a motor with a power rating of less than 1 kW. Upon shutdown, contact KMi (or KM2) releases, allowing capacitor C to discharge into the motor stator windings, which generates brake torque for rapid stopping.

The circuit operates on the principle of energy storage in a capacitor, which is charged during the motor's operation. When the motor needs to be stopped, the release of contact KMi (or KM2) initiates the discharge of the stored energy in capacitor C. This discharge occurs into the motor's stator windings, creating a magnetic field that opposes the motion of the rotor. The interaction between the magnetic field generated by the discharging capacitor and the rotor's magnetic field produces a braking torque, effectively slowing down and stopping the motor quickly.

This method of braking is particularly advantageous for applications requiring frequent starts and stops, as it avoids the complexities and losses associated with mechanical braking systems or step-down transformers. By relying on the rapid discharge of the capacitor, the circuit provides efficient and responsive braking action, reducing wear on mechanical components and enhancing the overall lifespan of the motor system.

The design of the circuit must ensure that the capacitor is appropriately rated for the voltage and current levels encountered in the application. Additionally, the choice of contacts KMi and KM2 should be made based on their ability to handle the load and the operational frequency of the motor. Proper sizing of the capacitor C is crucial to provide sufficient energy for effective braking without exceeding the component ratings.

In summary, this circuit design offers a compact and efficient solution for controlling small motors, leveraging capacitor discharge for braking while eliminating the need for bulky transformers, thus simplifying the overall system architecture. Circuit shown in Figure 3-146. This eliminates the need for a step-down transformer line, using the principle of energy storage capacitor discharge realization brake, it can be used to start and stop frequently, power llkW less motor. Shutdown, contact KMi (or KM2) release, capacitor C discharges to the motor stator windings, resulting in brake torque, stop quickly.

The circuit operates on the principle of energy storage in a capacitor, which is charged during the motor's operation. When the motor needs to be stopped, the release of contact KMi (or KM2) initiates the discharge of the stored energy in capacitor C. This discharge occurs into the motor's stator windings, creating a magnetic field that opposes the motion of the rotor. The interaction between the magnetic field generated by the discharging capacitor and the rotor's magnetic field produces a braking torque, effectively slowing down and stopping the motor quickly.

This method of braking is particularly advantageous for applications requiring frequent starts and stops, as it avoids the complexities and losses associated with mechanical braking systems or step-down transformers. By relying on the rapid discharge of the capacitor, the circuit provides efficient and responsive braking action, reducing wear on mechanical components and enhancing the overall lifespan of the motor system.

The design of the circuit must ensure that the capacitor is appropriately rated for the voltage and current levels encountered in the application. Additionally, the choice of contacts KMi and KM2 should be made based on their ability to handle the load and the operational frequency of the motor. Proper sizing of the capacitor C is crucial to provide sufficient energy for effective braking without exceeding the component ratings.

In summary, this circuit design offers a compact and efficient solution for controlling small motors, leveraging capacitor discharge for braking while eliminating the need for bulky transformers, thus simplifying the overall system architecture. Circuit shown in Figure 3-146. This eliminates the need for a step-down transformer line, using the principle of energy storage capacitor discharge realization brake, it can be used to start and stop frequently, power llkW less motor. Shutdown, contact KMi (or KM2) release, capacitor C discharges to the motor stator windings, resulting in brake torque, stop quickly.