Time relay three-start circuit

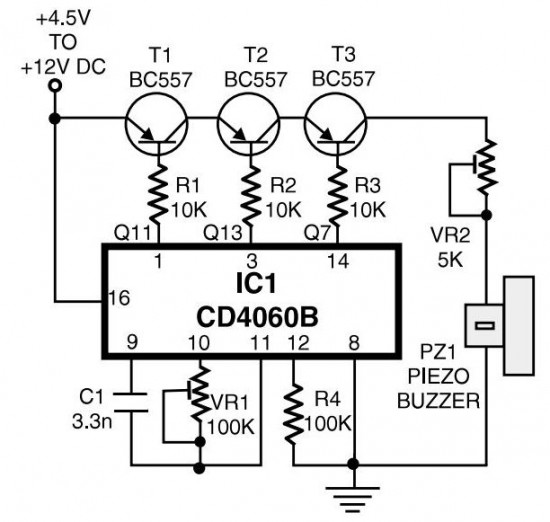

The circuit depicted in Figure 3-159 employs complementary operation three times along with three relay contacts. This is followed by the automatic elimination of the rotor circuit resistance levels, ultimately reducing the rotor winding variable resistor to zero (fully shorted), which allows the electric motor speed to gradually increase until it reaches the rated speed.

The circuit design utilizes a series of relays to facilitate the gradual increase in motor speed. The three relay contacts serve to control the engagement and disengagement of different resistance levels in the rotor circuit. Initially, the motor operates with a higher resistance, which limits the current flow and consequently the speed of the motor.

As the motor begins to operate, the first relay is activated, which reduces the resistance in the rotor circuit, allowing more current to flow. This increase in current results in a corresponding increase in motor speed. The second relay further decreases the resistance, and the process continues until the third relay is activated.

At this final stage, the rotor winding variable resistor is effectively shorted out, allowing maximum current to flow through the motor windings. This configuration ensures that the motor accelerates smoothly and reaches its rated speed without abrupt changes that could potentially damage the motor or connected components.

The automatic removal of resistance levels is crucial for protecting the motor during startup, as it prevents excessive current draw that could lead to overheating or burnout. The use of complementary operation in the relays ensures that the transition between different resistance levels is seamless, maintaining a stable and controlled acceleration profile for the motor.

Overall, this circuit is an effective solution for applications requiring precise control over electric motor speed, combining reliability and efficiency through its relay-based design. Circuit shown in Figure 3-159. The circuit uses complement each other three times and three relay contacts, followed by the automatic removal of the rotor circuit resistance le vels, and finally the rotor winding variable resistor is reduced to zero (all short), so that the electric motor speed gradually increased, and finally reach the rated speed.

The circuit design utilizes a series of relays to facilitate the gradual increase in motor speed. The three relay contacts serve to control the engagement and disengagement of different resistance levels in the rotor circuit. Initially, the motor operates with a higher resistance, which limits the current flow and consequently the speed of the motor.

As the motor begins to operate, the first relay is activated, which reduces the resistance in the rotor circuit, allowing more current to flow. This increase in current results in a corresponding increase in motor speed. The second relay further decreases the resistance, and the process continues until the third relay is activated.

At this final stage, the rotor winding variable resistor is effectively shorted out, allowing maximum current to flow through the motor windings. This configuration ensures that the motor accelerates smoothly and reaches its rated speed without abrupt changes that could potentially damage the motor or connected components.

The automatic removal of resistance levels is crucial for protecting the motor during startup, as it prevents excessive current draw that could lead to overheating or burnout. The use of complementary operation in the relays ensures that the transition between different resistance levels is seamless, maintaining a stable and controlled acceleration profile for the motor.

Overall, this circuit is an effective solution for applications requiring precise control over electric motor speed, combining reliability and efficiency through its relay-based design. Circuit shown in Figure 3-159. The circuit uses complement each other three times and three relay contacts, followed by the automatic removal of the rotor circuit resistance le vels, and finally the rotor winding variable resistor is reduced to zero (all short), so that the electric motor speed gradually increased, and finally reach the rated speed.