Transformerless 5 Volt Power Supply

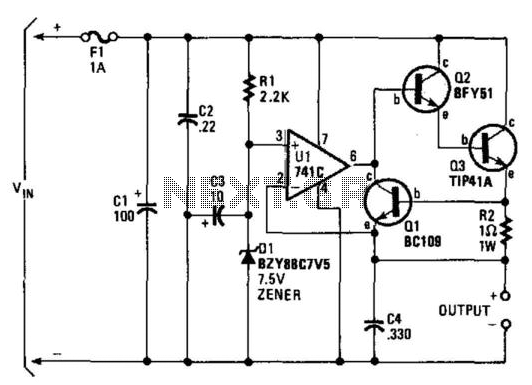

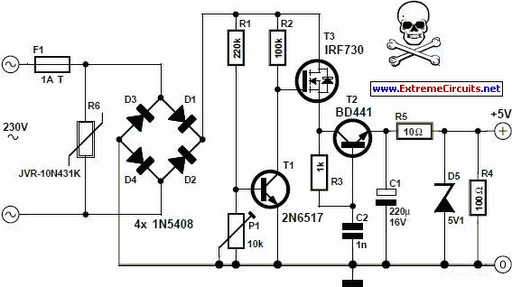

An increasing number of appliances draw a very small current from the power supply. When designing a mains-powered device, one typically chooses between a linear and a switch-mode power supply. However, for appliances with very low total power consumption, transformer-based power supplies tend to be bulky, while switch-mode supplies are generally designed for higher current outputs, which increases complexity and can lead to PCB layout challenges and reduced reliability. Is it feasible to create a simple, minimal part-count mains (230 VAC primary) power supply without transformers or coils, capable of delivering approximately 100 mA at 5 V? A potential approach involves using a highly inefficient stabilizer that rectifies AC and employs a zener diode to provide a 5.1 V output, dissipating excess voltage from 5.1 V up to (230 - v2) volts across a resistor. Even for a load requiring only about 10 mA, this could result in approximately 3 watts of power loss, leading to significant heat dissipation even for minimal power consumption. At 100 mA, the unnecessary power dissipation could exceed 30 W, rendering this method impractical. The main challenge is to minimize heat dissipation and protect components from overheating. The presented circuit represents one of the simplest methods to achieve these objectives. A JVR varistor is utilized for overvoltage and surge protection. A voltage divider (R1-R2) follows the rectified 230 V. When the voltage is sufficiently high, transistor T1 turns on, preventing T3 from conducting. As the rectified voltage decreases, T1 turns off, allowing T3 to conduct current into the reservoir capacitor C1. The cutoff point (when T1 turns off) is determined by potentiometer P1 (typically set to about 3.3 kΩ), which controls the overall output current capacity of the power supply. Reducing P1 delays T1's response, allowing T3 to conduct for longer, resulting in increased current supply but also greater heat dissipation. Components T2, R3, and C2 form a soft start circuit to mitigate current spikes, which is crucial for limiting C1's charging current during initial power-up. At a specific P1 setting, the output current through resistor R5 remains constant. Load resistor R4 draws the current it requires, with the excess flowing through zener diode D5. By knowing the maximum current drawn by the load, P1 can be adjusted to ensure the total current through R5 is only 5 to 6 mA above the load's maximum requirement. This approach significantly reduces unnecessary dissipation while maintaining zener stabilization. Zener diode D5 also safeguards C1 from overvoltage, allowing the use of low-cost 16 V electrolytic capacitors. The current through R5 and D5, even when the load is disconnected, prevents excessive gate-source voltage on T3, protecting the device from damage. Additionally, T1 does not need to be a high-voltage transistor, but should have a current gain exceeding 120 (e.g., BC546B or BC547C can be used). It is important to note that this circuit is not galvanically isolated from the mains. Contacting any part of the circuit (or any connected circuitry) while in operation poses a risk of electric shock. This circuit should not be constructed or operated by individuals lacking proper knowledge of mains voltage safety procedures.

The circuit design described employs a clever use of components to achieve a low-cost, low-part-count solution for powering small appliances from a mains supply. The inclusion of a JVR varistor for surge protection is critical, as it helps prevent damage from voltage spikes that can occur in mains electricity. The voltage divider formed by resistors R1 and R2 is essential for monitoring the rectified voltage and controlling the switching action of transistor T1. The feedback mechanism involving P1 allows for fine-tuning of the output current, ensuring that the circuit can adapt to varying load conditions while minimizing excess heat generation.

The soft start circuit, comprising T2, R3, and C2, is particularly important in applications where inrush current can cause damage to components or lead to instability in the power supply. By controlling the charging rate of C1, the circuit mitigates the risk of high initial currents, contributing to overall reliability.

The choice of zener diode D5 not only serves the purpose of voltage regulation but also acts as a protective element for C1, allowing for the use of lower voltage-rated capacitors, which can reduce overall costs. The design's consideration for current flow through R5 and D5 when the load is disconnected ensures that T3 remains protected from potentially damaging voltage levels, which enhances the circuit's robustness.

Overall, this circuit exemplifies an innovative approach to powering low-consumption devices from mains voltage, balancing efficiency, simplicity, and safety considerations. However, it is essential to emphasize the importance of adhering to safety standards when working with mains-powered circuits to prevent accidents and ensure safe operation.An increasing number of appliances draw a very small current from the power supply. If you need to design a mains powered device, you could generally choose between a linear and a switch-mode power supply. However, what if the appliance`s total power consumption is very small Transformer-based power supplies are bulky, while the switchers are gen

erally made to provide greater current output, with a significant increase in complexity, problems involving PCB layout and, inherently, reduced reliability. Is it possible to create a simple, minimum part-count mains (230 VAC primary) power supply, without transformers or coils, capable of delivering about 100 mA at, say, 5 V A general approach could be to employ a highly inefficient stabilizer that would rectify AC and, utilizing a zener diode to provide a 5.

1 V output, dissipate all the excess from 5. 1 V to (230G—v2) volts in a resistor. Even if the load would require only about 10 mA, the loss would be approximately 3 watts, so a significant heat dissipation would occur even for such a small power consumption. At 100 mA, the useless dissipation would go over 30 W, making this scheme completely unacceptable. Power conversion efficiency is not a major consideration here; instead, the basic problem is how to reduce heavy dissipation and protect the components from burning out.

The circuit shown here is one of the simplest ways to achieve the above goals in practice. A JVR varistor is used for overvoltage/surge protection. Voltage divider R1-R2 follows the rectified 230 V and, when it is high enough, T1 turns on and T3 cannot conduct. When the rectified voltage drops, T1 turns off and T3 starts to conduct current into the reservoir capacitor C1.

The interception point (the moment when T1 turns off) is set by P1 (usually set to about 3k3), which controls the total output current capacity of the power supply: reducing P1 makes T1 react later, stopping T3 later, so more current is supplied, but with increased heat dissipation. Components T2, R3 and C2 form a typical soft start` circuit to reduce current spikes this is necessary in order to limit C1`s charging current when the power supply is initially turned on.

At a given setting of P1, the output current through R5 is constant. Thus, load R4 takes as much current as it requires, while the rest goes through a zener diode, D5. Knowing the maximum current drawn by the load allows adjusting P1 to such a value as to provide a total current through R5 just 5 to 6 mA over the maximum required by the load. In this way, unnecessary dissipation is much reduced, with zener stabilization function preserved. Zener diode D5 also protects C1 from over voltages, thus enabling te use of low-cost 16 V electrolytics.

The current flow through R5 and D5, even when the load is disconnected, prevents T3`s gate-source voltage from rising too much and causing damage to device. In addition, T1 need not be a high-voltage transistor, but its current gain should exceed 120 (e. g. BC546B, or even BC547C can be used). The circuit is not galvanically isolated from the mains. Touching any part of the circuit (or any circuitry it supplies power to) while in operation, is dangerous and can result in an electric shock!

This circuit should not be built or used by individuals without proper knowledge of mains voltage procedures. 🔗 External reference

The circuit design described employs a clever use of components to achieve a low-cost, low-part-count solution for powering small appliances from a mains supply. The inclusion of a JVR varistor for surge protection is critical, as it helps prevent damage from voltage spikes that can occur in mains electricity. The voltage divider formed by resistors R1 and R2 is essential for monitoring the rectified voltage and controlling the switching action of transistor T1. The feedback mechanism involving P1 allows for fine-tuning of the output current, ensuring that the circuit can adapt to varying load conditions while minimizing excess heat generation.

The soft start circuit, comprising T2, R3, and C2, is particularly important in applications where inrush current can cause damage to components or lead to instability in the power supply. By controlling the charging rate of C1, the circuit mitigates the risk of high initial currents, contributing to overall reliability.

The choice of zener diode D5 not only serves the purpose of voltage regulation but also acts as a protective element for C1, allowing for the use of lower voltage-rated capacitors, which can reduce overall costs. The design's consideration for current flow through R5 and D5 when the load is disconnected ensures that T3 remains protected from potentially damaging voltage levels, which enhances the circuit's robustness.

Overall, this circuit exemplifies an innovative approach to powering low-consumption devices from mains voltage, balancing efficiency, simplicity, and safety considerations. However, it is essential to emphasize the importance of adhering to safety standards when working with mains-powered circuits to prevent accidents and ensure safe operation.An increasing number of appliances draw a very small current from the power supply. If you need to design a mains powered device, you could generally choose between a linear and a switch-mode power supply. However, what if the appliance`s total power consumption is very small Transformer-based power supplies are bulky, while the switchers are gen

erally made to provide greater current output, with a significant increase in complexity, problems involving PCB layout and, inherently, reduced reliability. Is it possible to create a simple, minimum part-count mains (230 VAC primary) power supply, without transformers or coils, capable of delivering about 100 mA at, say, 5 V A general approach could be to employ a highly inefficient stabilizer that would rectify AC and, utilizing a zener diode to provide a 5.

1 V output, dissipate all the excess from 5. 1 V to (230G—v2) volts in a resistor. Even if the load would require only about 10 mA, the loss would be approximately 3 watts, so a significant heat dissipation would occur even for such a small power consumption. At 100 mA, the useless dissipation would go over 30 W, making this scheme completely unacceptable. Power conversion efficiency is not a major consideration here; instead, the basic problem is how to reduce heavy dissipation and protect the components from burning out.

The circuit shown here is one of the simplest ways to achieve the above goals in practice. A JVR varistor is used for overvoltage/surge protection. Voltage divider R1-R2 follows the rectified 230 V and, when it is high enough, T1 turns on and T3 cannot conduct. When the rectified voltage drops, T1 turns off and T3 starts to conduct current into the reservoir capacitor C1.

The interception point (the moment when T1 turns off) is set by P1 (usually set to about 3k3), which controls the total output current capacity of the power supply: reducing P1 makes T1 react later, stopping T3 later, so more current is supplied, but with increased heat dissipation. Components T2, R3 and C2 form a typical soft start` circuit to reduce current spikes this is necessary in order to limit C1`s charging current when the power supply is initially turned on.

At a given setting of P1, the output current through R5 is constant. Thus, load R4 takes as much current as it requires, while the rest goes through a zener diode, D5. Knowing the maximum current drawn by the load allows adjusting P1 to such a value as to provide a total current through R5 just 5 to 6 mA over the maximum required by the load. In this way, unnecessary dissipation is much reduced, with zener stabilization function preserved. Zener diode D5 also protects C1 from over voltages, thus enabling te use of low-cost 16 V electrolytics.

The current flow through R5 and D5, even when the load is disconnected, prevents T3`s gate-source voltage from rising too much and causing damage to device. In addition, T1 need not be a high-voltage transistor, but its current gain should exceed 120 (e. g. BC546B, or even BC547C can be used). The circuit is not galvanically isolated from the mains. Touching any part of the circuit (or any circuitry it supplies power to) while in operation, is dangerous and can result in an electric shock!

This circuit should not be built or used by individuals without proper knowledge of mains voltage procedures. 🔗 External reference