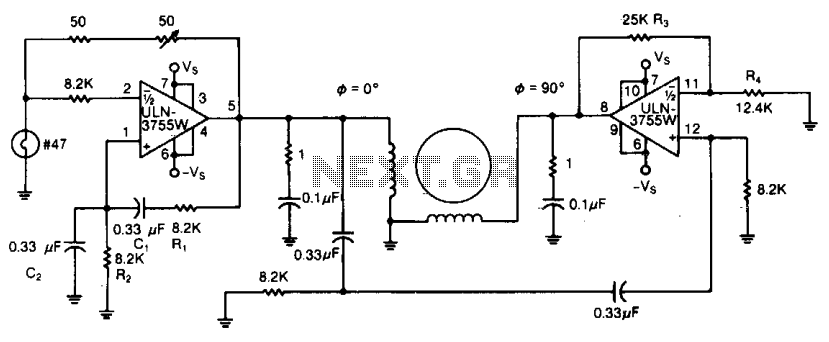

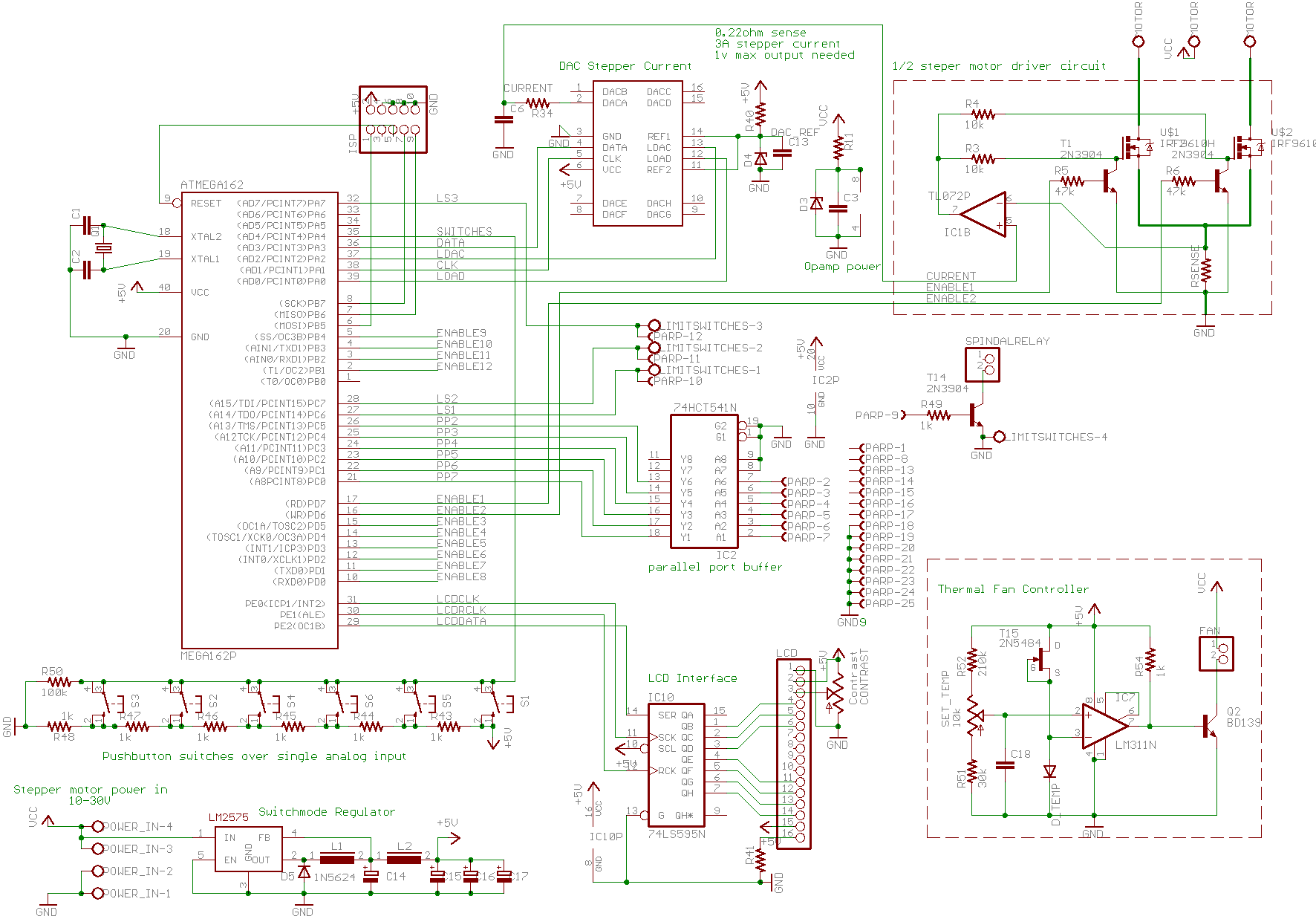

unipolar microstepping linear constant current stepper motor controller

A basic CNC machine was built for a university project, and the completed machine will undergo upgrades over the coming months. The plan includes replacing the small 48-step stepper motors with larger 200-step motors to enhance performance.

The project involves a fundamental understanding of CNC (Computer Numerical Control) systems, where precise motor control is essential for accurate machining. The transition from 48-step to 200-step stepper motors will significantly improve the resolution and torque of the CNC machine.

Stepper motors operate by dividing a full rotation into a series of discrete steps, allowing for precise control of position and movement. The 200-step motors provide finer resolution, enabling smoother motion and greater accuracy in the machining process. This increase in step count translates to smaller incremental movements, which is particularly beneficial for applications requiring high precision.

To implement this upgrade, the following components and considerations are crucial:

1. **Driver Circuit**: The stepper motor drivers must be compatible with the new motors. A suitable driver will provide the necessary current and voltage to operate the 200-step motors efficiently. It is essential to select a driver that supports microstepping, which further enhances the resolution and smoothness of motor operation.

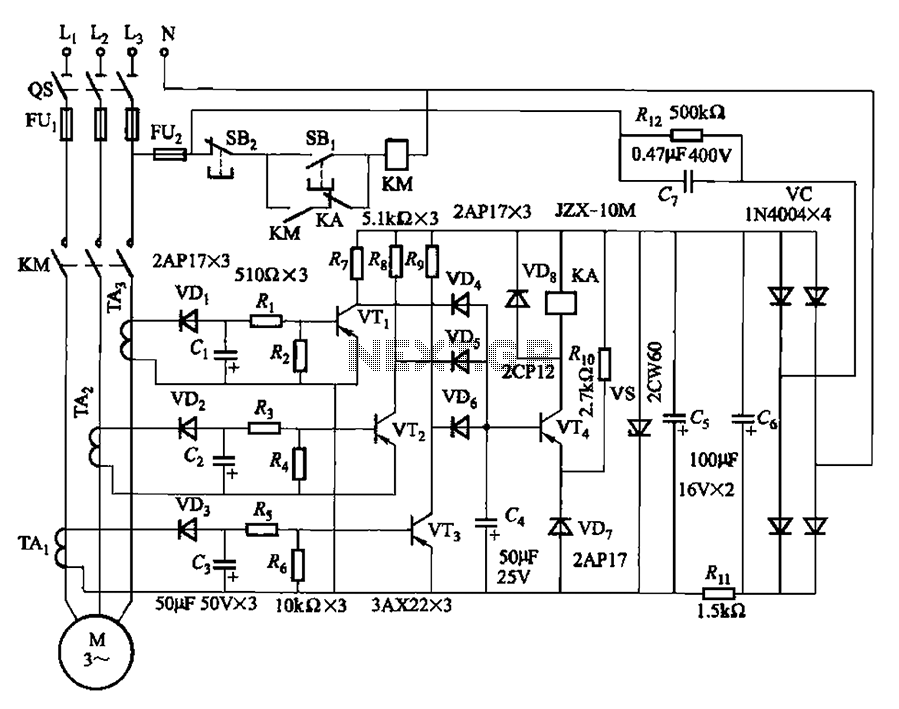

2. **Power Supply**: The power supply must be evaluated to ensure it can deliver the required voltage and current for the larger stepper motors. An increase in motor size may necessitate a power supply upgrade to maintain performance and prevent overheating.

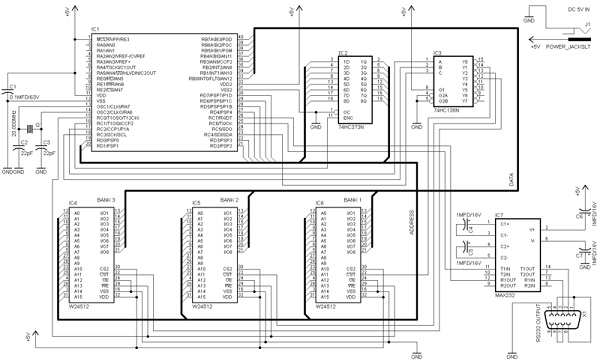

3. **Control System**: The CNC controller must be capable of handling the increased step count. This may involve updating the firmware or software used to control the CNC machine to ensure compatibility with the new motors and drivers.

4. **Mechanical Considerations**: The mounting and coupling of the new motors to the existing mechanical components must be assessed. Proper alignment and secure attachment are vital to prevent mechanical failures or loss of precision during operation.

5. **Testing and Calibration**: Following the installation of the new motors, thorough testing and calibration will be necessary to ensure the CNC machine operates correctly. This includes adjusting settings for acceleration, deceleration, and maximum speed to optimize performance based on the new motor specifications.

By upgrading to 200-step stepper motors, the CNC machine is expected to achieve higher precision and improved performance, making it more suitable for advanced machining tasks in future projects.Building a basic CNC Machine for a university project, I ended up getting to keep the finished machine and will be upgrading it over the months. Upgrading the small 48step stepper motors for big 200step beasts, I want to really get the best I can out of them so that`s where this new stepper motor.

🔗 External reference

The project involves a fundamental understanding of CNC (Computer Numerical Control) systems, where precise motor control is essential for accurate machining. The transition from 48-step to 200-step stepper motors will significantly improve the resolution and torque of the CNC machine.

Stepper motors operate by dividing a full rotation into a series of discrete steps, allowing for precise control of position and movement. The 200-step motors provide finer resolution, enabling smoother motion and greater accuracy in the machining process. This increase in step count translates to smaller incremental movements, which is particularly beneficial for applications requiring high precision.

To implement this upgrade, the following components and considerations are crucial:

1. **Driver Circuit**: The stepper motor drivers must be compatible with the new motors. A suitable driver will provide the necessary current and voltage to operate the 200-step motors efficiently. It is essential to select a driver that supports microstepping, which further enhances the resolution and smoothness of motor operation.

2. **Power Supply**: The power supply must be evaluated to ensure it can deliver the required voltage and current for the larger stepper motors. An increase in motor size may necessitate a power supply upgrade to maintain performance and prevent overheating.

3. **Control System**: The CNC controller must be capable of handling the increased step count. This may involve updating the firmware or software used to control the CNC machine to ensure compatibility with the new motors and drivers.

4. **Mechanical Considerations**: The mounting and coupling of the new motors to the existing mechanical components must be assessed. Proper alignment and secure attachment are vital to prevent mechanical failures or loss of precision during operation.

5. **Testing and Calibration**: Following the installation of the new motors, thorough testing and calibration will be necessary to ensure the CNC machine operates correctly. This includes adjusting settings for acceleration, deceleration, and maximum speed to optimize performance based on the new motor specifications.

By upgrading to 200-step stepper motors, the CNC machine is expected to achieve higher precision and improved performance, making it more suitable for advanced machining tasks in future projects.Building a basic CNC Machine for a university project, I ended up getting to keep the finished machine and will be upgrading it over the months. Upgrading the small 48step stepper motors for big 200step beasts, I want to really get the best I can out of them so that`s where this new stepper motor.

🔗 External reference