Wiring up to the AN2131

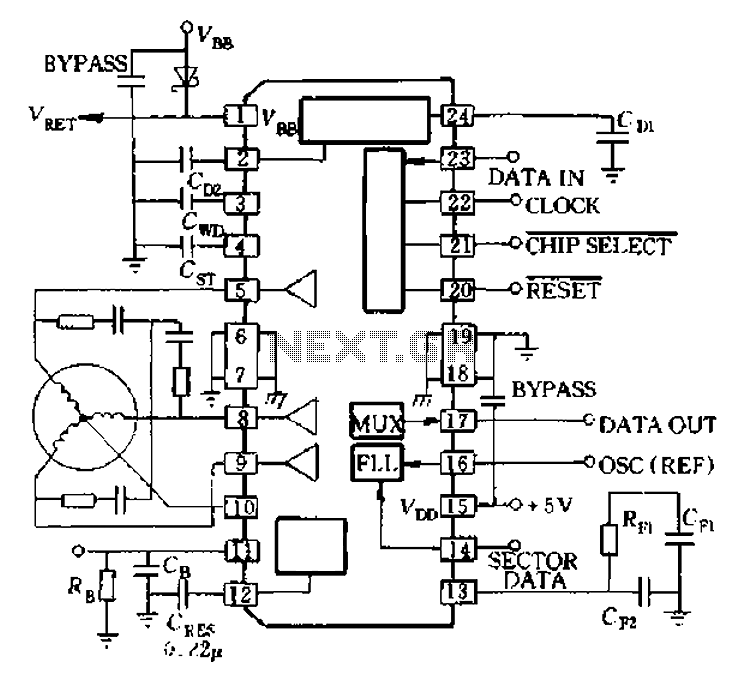

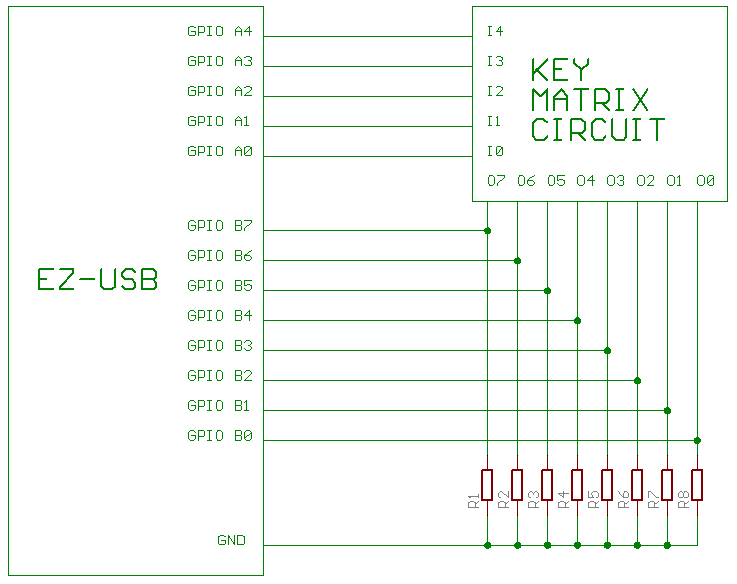

The circuit utilizes an AN2131 chip accompanied by the necessary support components, including a crystal oscillator and power regulators. The inputs and outputs of the key matrix were connected to the GPIO ports of the AN2131 through a protoboard. However, this setup encountered issues where the keys would frequently become "stuck." This problem arose from unconnected chip pins that could "float" between on and off states due to residual charge in the wiring. To resolve this, pull-down resistors were incorporated to allow any residual charge to discharge to ground when the keys are released. One pull-down resistor was added to each input of the circuit, utilizing various spare resistors ranging from 320 ohms to 1000 ohms.

The AN2131 chip is a microcontroller designed for handling input and output operations, particularly in embedded systems. The integration of a crystal oscillator is critical for providing a stable clock signal, ensuring the microcontroller operates at the desired frequency. Power regulators are essential for supplying the appropriate voltage levels to the AN2131 and supporting components, maintaining operational integrity.

The key matrix serves as an interface for user input, where each key press corresponds to a unique signal. The GPIO ports of the AN2131 are configured to read these signals. However, without proper termination, floating inputs can lead to erratic behavior, such as keys appearing to be continuously pressed. The implementation of pull-down resistors effectively mitigates this issue by ensuring that the GPIO pins are pulled to a low state when not actively driven high by a key press.

The choice of pull-down resistor values, ranging from 320 ohms to 1000 ohms, indicates a consideration for both power consumption and response time. Lower resistance values will provide a quicker discharge of residual charge but may draw slightly more current when the keys are pressed. Conversely, higher resistance values reduce current draw but may result in slower response times. The final circuit diagram would illustrate the connections between the AN2131, the key matrix, and the pull-down resistors, ensuring clarity in the design and functionality of the circuit.It`s just a AN2131 chip with the required support circuitry - crystal oscillator, power regulators etc. First I took the inputs and outputs of the key matrix and wired them to the GPIO ports of the AN2131.

This was just a matter of plugging the whole lot into some protoboard. This didn`t work too well, as the keys would get "stuck" often. This is because an unconnected chip leg can "float" between on and off due to the residual charge held in the wire. The solution is to add pull-down resistors which allow this residual charge to flow to ground when the key is released. I added one to each input of the circuit. I used a variety of spare resistors from the junk box 320 ohms to 1000 ohms. This is the final circuit diagram: 🔗 External reference

The AN2131 chip is a microcontroller designed for handling input and output operations, particularly in embedded systems. The integration of a crystal oscillator is critical for providing a stable clock signal, ensuring the microcontroller operates at the desired frequency. Power regulators are essential for supplying the appropriate voltage levels to the AN2131 and supporting components, maintaining operational integrity.

The key matrix serves as an interface for user input, where each key press corresponds to a unique signal. The GPIO ports of the AN2131 are configured to read these signals. However, without proper termination, floating inputs can lead to erratic behavior, such as keys appearing to be continuously pressed. The implementation of pull-down resistors effectively mitigates this issue by ensuring that the GPIO pins are pulled to a low state when not actively driven high by a key press.

The choice of pull-down resistor values, ranging from 320 ohms to 1000 ohms, indicates a consideration for both power consumption and response time. Lower resistance values will provide a quicker discharge of residual charge but may draw slightly more current when the keys are pressed. Conversely, higher resistance values reduce current draw but may result in slower response times. The final circuit diagram would illustrate the connections between the AN2131, the key matrix, and the pull-down resistors, ensuring clarity in the design and functionality of the circuit.It`s just a AN2131 chip with the required support circuitry - crystal oscillator, power regulators etc. First I took the inputs and outputs of the key matrix and wired them to the GPIO ports of the AN2131.

This was just a matter of plugging the whole lot into some protoboard. This didn`t work too well, as the keys would get "stuck" often. This is because an unconnected chip leg can "float" between on and off due to the residual charge held in the wire. The solution is to add pull-down resistors which allow this residual charge to flow to ground when the key is released. I added one to each input of the circuit. I used a variety of spare resistors from the junk box 320 ohms to 1000 ohms. This is the final circuit diagram: 🔗 External reference