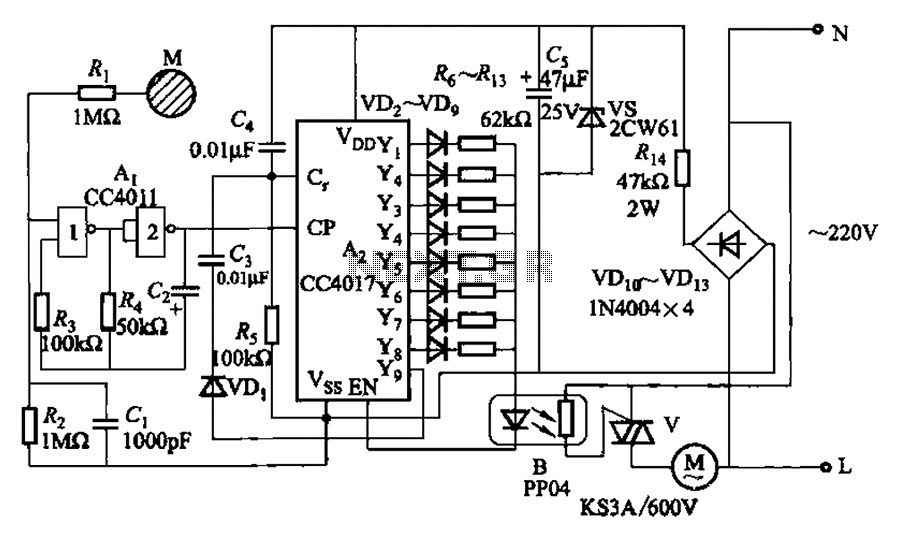

Touch fan speed control circuit eight stalls

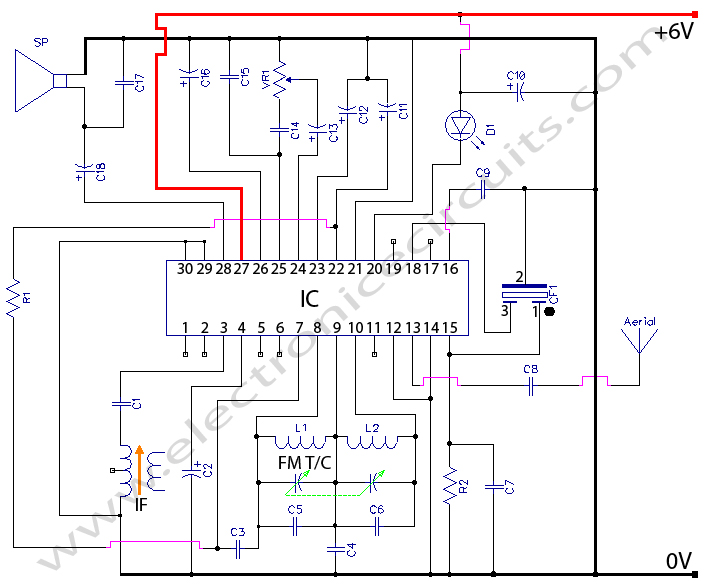

The circuit depicted in Figure 3-7 utilizes a touch sensor chip in conjunction with a conductive sheet. It is designed to achieve eight different speed settings. The CC4011 timing pulse oscillator is comprised of an integrated circuit. The configuration includes two ND gates. When the conductive sheet is touched, the CC4017 generates a counting pulse, which is then outputted to the Y1 through Y9 pins. These outputs are activated via varying resistor values, which subsequently control the conduction angle of a TRIAC, thereby enabling the eight-speed settings. Resistors R6 and R62kC1, along with R7 and R1a, are crucial for calibration, ensuring that the voltage across the motor remains between 25V and 30V.

The circuit functions as follows: the touch sensor chip detects contact with the conductive sheet, initiating a signal that triggers the CC4011 timing pulse oscillator. This oscillator generates timing pulses that are fed into the ND gates, which perform logical operations to create a sequential output. The CC4017 counter then counts these pulses, with each output corresponding to a specific gear speed.

The outputs Y1 to Y9 are connected to a series of resistors that form a voltage divider network. The varying resistance values are essential for adjusting the output signals to the TRIAC, which controls the power delivered to the motor. By manipulating the conduction angle of the TRIAC, the circuit can effectively regulate the speed of the motor, allowing for smooth transitions between the eight different settings.

The resistors R6, R62kC1, R7, and R1a are selected based on the desired performance characteristics of the motor. These components must be fine-tuned during the debugging process to ensure that the voltage across the motor remains within the specified range of 25V to 30V, which is critical for optimal operation and to prevent potential damage to the motor or circuit components. Proper calibration of these resistors ensures the reliability and efficiency of the speed control mechanism, making it suitable for various applications requiring precise motor speed adjustments. Circuit shown in Figure 3-7. Just touch sensor chip (conductive sheet). Eight gear speed can be realized. CC4011 timing pulse oscillator consists of an integrated circuit Ai NA ND gate 1,2 composition. When touching conductive sheet M while, Ai Kai vibration that is to CC4017 ~ - into the counting/pulse divider Az issued counting pulse, the output of Yl A2 of ~ Y9 turn out high through different resistor values R ~ ~ Ria buck to the optocoupler B, and then control the TRIAC V conduction angle, to achieve eight gear speed. Resistors R6 level 62kC1, R7 ~ R1a required to determine the actual debugging, so that two adjacent block electrical pressure (voltage across the motor) the order of 25 ~ 30V.

The circuit functions as follows: the touch sensor chip detects contact with the conductive sheet, initiating a signal that triggers the CC4011 timing pulse oscillator. This oscillator generates timing pulses that are fed into the ND gates, which perform logical operations to create a sequential output. The CC4017 counter then counts these pulses, with each output corresponding to a specific gear speed.

The outputs Y1 to Y9 are connected to a series of resistors that form a voltage divider network. The varying resistance values are essential for adjusting the output signals to the TRIAC, which controls the power delivered to the motor. By manipulating the conduction angle of the TRIAC, the circuit can effectively regulate the speed of the motor, allowing for smooth transitions between the eight different settings.

The resistors R6, R62kC1, R7, and R1a are selected based on the desired performance characteristics of the motor. These components must be fine-tuned during the debugging process to ensure that the voltage across the motor remains within the specified range of 25V to 30V, which is critical for optimal operation and to prevent potential damage to the motor or circuit components. Proper calibration of these resistors ensures the reliability and efficiency of the speed control mechanism, making it suitable for various applications requiring precise motor speed adjustments. Circuit shown in Figure 3-7. Just touch sensor chip (conductive sheet). Eight gear speed can be realized. CC4011 timing pulse oscillator consists of an integrated circuit Ai NA ND gate 1,2 composition. When touching conductive sheet M while, Ai Kai vibration that is to CC4017 ~ - into the counting/pulse divider Az issued counting pulse, the output of Yl A2 of ~ Y9 turn out high through different resistor values R ~ ~ Ria buck to the optocoupler B, and then control the TRIAC V conduction angle, to achieve eight gear speed. Resistors R6 level 62kC1, R7 ~ R1a required to determine the actual debugging, so that two adjacent block electrical pressure (voltage across the motor) the order of 25 ~ 30V.