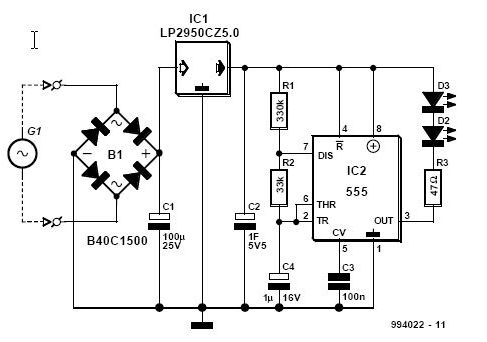

12V Glow Plug Converter

Most small internal combustion engines commonly used in the model-building world utilize glow plugs for starting. Unfortunately, glow plugs have an operating...

Glow plugs are essential components in many small internal combustion engines, particularly in the context of model building. These devices serve to preheat the air-fuel mixture in the combustion chamber, facilitating ignition during the starting phase of engine operation. The glow plug consists of a heating element, typically made from a high-resistance metal alloy, which heats up rapidly when an electrical current is applied.

The operation of a glow plug begins when the engine is turned on, and a voltage is supplied to the plug. This voltage heats the coil within the glow plug to a temperature sufficient to ignite the fuel-air mixture. The typical operating temperature for a glow plug can range from 1000°C to 1200°C, depending on the design and application.

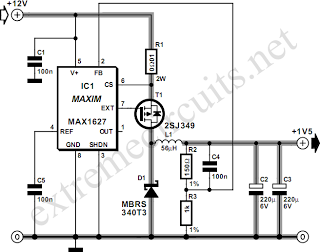

In many model engines, a battery or an external power supply is used to provide the necessary current to the glow plug. The circuit often includes a switch that allows the user to control the activation of the glow plug. A resistor may also be included in the circuit to limit the current and prevent damage to the glow plug during prolonged operation.

Once the engine starts, the glow plug may remain heated for a short period to ensure smooth operation during initial running. Some advanced systems may integrate a timer or a temperature sensor to optimize the glow plug's operation, enhancing engine performance and reliability.

Overall, the integration of glow plugs in small internal combustion engines is a critical aspect of their design, influencing both the starting process and overall engine efficiency. Proper understanding and management of the glow plug circuit can lead to improved performance and longevity of the engine in model-building applications.Most small internal-combustion engines commonly used in the model-building world use glow plugs for starting. Unfortunately, glow plugs have an operating.. 🔗 External reference

Glow plugs are essential components in many small internal combustion engines, particularly in the context of model building. These devices serve to preheat the air-fuel mixture in the combustion chamber, facilitating ignition during the starting phase of engine operation. The glow plug consists of a heating element, typically made from a high-resistance metal alloy, which heats up rapidly when an electrical current is applied.

The operation of a glow plug begins when the engine is turned on, and a voltage is supplied to the plug. This voltage heats the coil within the glow plug to a temperature sufficient to ignite the fuel-air mixture. The typical operating temperature for a glow plug can range from 1000°C to 1200°C, depending on the design and application.

In many model engines, a battery or an external power supply is used to provide the necessary current to the glow plug. The circuit often includes a switch that allows the user to control the activation of the glow plug. A resistor may also be included in the circuit to limit the current and prevent damage to the glow plug during prolonged operation.

Once the engine starts, the glow plug may remain heated for a short period to ensure smooth operation during initial running. Some advanced systems may integrate a timer or a temperature sensor to optimize the glow plug's operation, enhancing engine performance and reliability.

Overall, the integration of glow plugs in small internal combustion engines is a critical aspect of their design, influencing both the starting process and overall engine efficiency. Proper understanding and management of the glow plug circuit can lead to improved performance and longevity of the engine in model-building applications.Most small internal-combustion engines commonly used in the model-building world use glow plugs for starting. Unfortunately, glow plugs have an operating.. 🔗 External reference