200 solar charged remote control lawn mower

Develop a device that operates independently of gasoline, is user-friendly, can serve as a backup energy source, and allows for sharing the construction process with others. The instructional video series is structured similarly to a previous large project that demonstrated how to build a 63W solar panel and solar-powered system. The series consists of 14 videos, including an introductory video that provides detailed explanations on the creation of the SCRCELM.

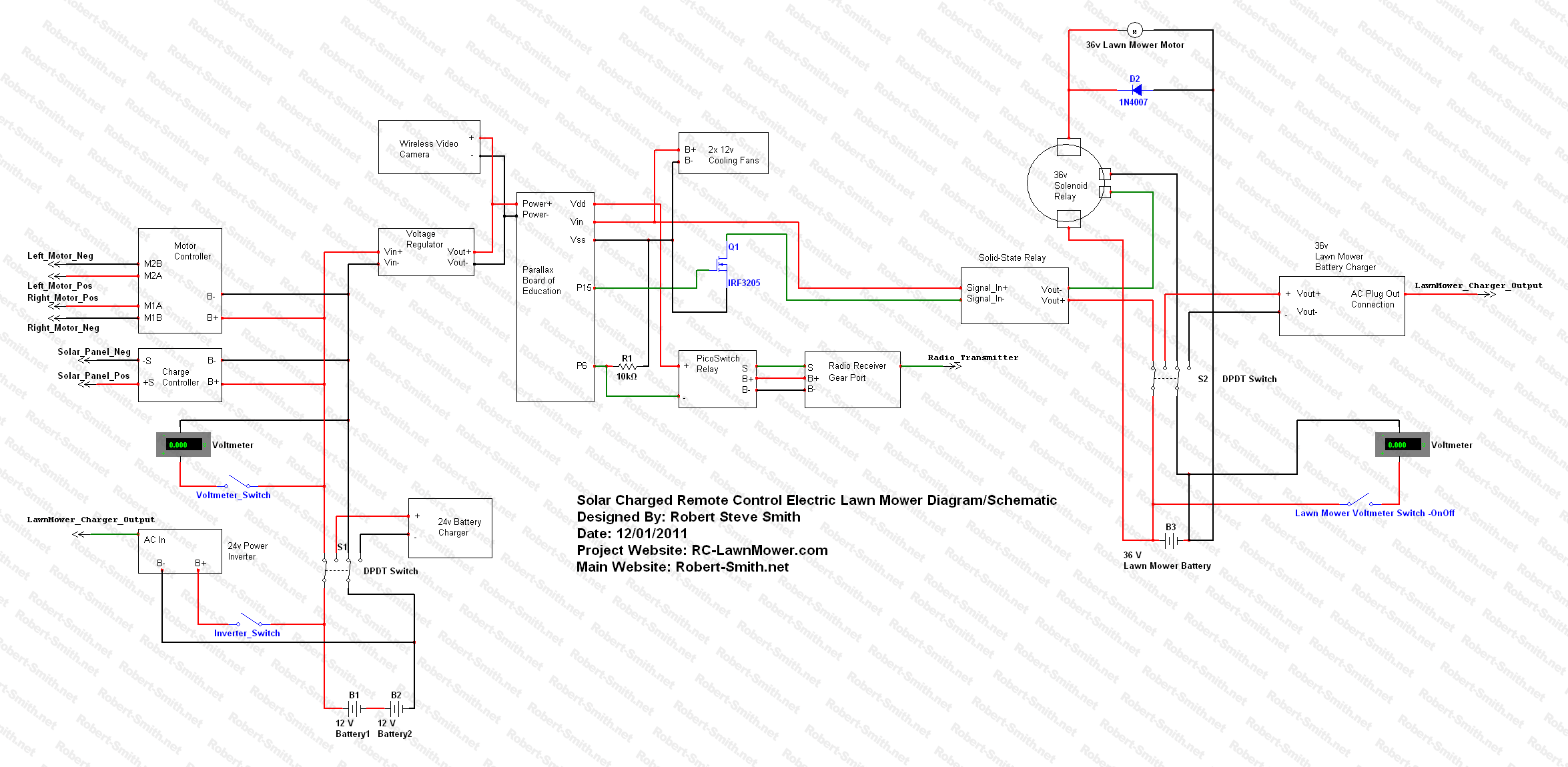

If there are any inquiries, it is recommended to first consult the FAQ page. If the question is not addressed there, the contact page at Robert-Smith.net can be visited. Significant effort was dedicated to producing these videos, and feedback in the form of ratings, subscriptions, or comments is appreciated. The project required approximately 130 man-hours to complete, with the majority of the time allocated to constructing the aluminum frame, followed by research and development. The estimated weight of the device is slightly over 200 lbs, and the total project cost is projected to exceed $1500. Key components contributing to the cost include a rechargeable electric lawn mower, solar panels, a solar charge controller, a motor controller, and motors from an electric wheelchair.

The SCRCELM device represents an innovative approach to sustainable energy solutions, integrating various components to create a functional and efficient system. The design emphasizes simplicity in operation, making it accessible for users with varying levels of technical expertise. The instructional videos guide viewers through each phase of construction, from initial planning and material selection to the assembly of the aluminum frame and integration of the electrical components.

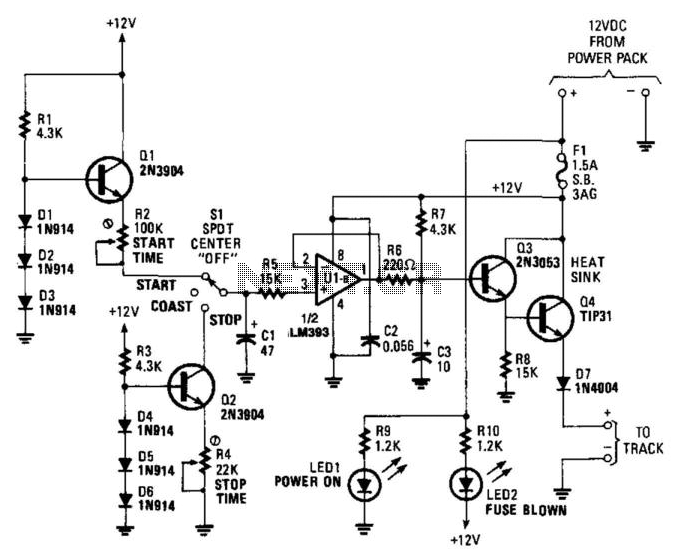

The use of solar panels as a primary energy source underscores the project's commitment to renewable energy, while the rechargeable electric lawn mower serves as a practical example of how existing technologies can be repurposed. The solar charge controller plays a critical role in managing the energy flow from the solar panels to the battery storage system, ensuring optimal charging and preventing over-discharge. The motor controller is essential for regulating the operation of the electric wheelchair motors, allowing for precise control of the device's movement and functionality.

The overall design prioritizes durability and efficiency, with the aluminum frame providing a robust structure capable of supporting the weight of the components while remaining lightweight. The estimated project cost reflects the investment in high-quality materials and components, which are crucial for the longevity and performance of the device.

In conclusion, the SCRCELM project not only serves as a viable alternative to gasoline-powered devices but also exemplifies the potential for creative solutions in the realm of renewable energy. The comprehensive video series acts as a valuable resource for individuals interested in replicating the project or gaining insights into the construction of similar devices.Create a device that did not rely on gasoline, was simple to operate, could be used as a backup energy source, and to share with others how I built the device. The how-to video series is setup very similar to my previous large project which was showing others how to build a 63W solar panel and solar powered system.

There are a total of 14 videos, including the intro video, where I explain in great detail how I created the SCRCELM. If you have any questions, please visit my FAQ page first, and if your question is not listed there, visit my contact page at: Robert-Smith. net. I put a lot of time and effort into producing these videos, so if you find them interesting or helpful, please rate, subscribe, or leave a comment.

The amount of time it took to complete this project was roughly 130 man hours. Most of the time was spent creating the aluminum frame. The next bulk of time was spent on research and development. I estimated the weight of the device to be a little over 200lbs. The total cost of the project was estimated to be a little over $1500. 00. Some of the most expensive items were the rechargeable electric lawn mower, solar panels, solar charge controller, motor controller, and electric wheelchair motors. 🔗 External reference

If there are any inquiries, it is recommended to first consult the FAQ page. If the question is not addressed there, the contact page at Robert-Smith.net can be visited. Significant effort was dedicated to producing these videos, and feedback in the form of ratings, subscriptions, or comments is appreciated. The project required approximately 130 man-hours to complete, with the majority of the time allocated to constructing the aluminum frame, followed by research and development. The estimated weight of the device is slightly over 200 lbs, and the total project cost is projected to exceed $1500. Key components contributing to the cost include a rechargeable electric lawn mower, solar panels, a solar charge controller, a motor controller, and motors from an electric wheelchair.

The SCRCELM device represents an innovative approach to sustainable energy solutions, integrating various components to create a functional and efficient system. The design emphasizes simplicity in operation, making it accessible for users with varying levels of technical expertise. The instructional videos guide viewers through each phase of construction, from initial planning and material selection to the assembly of the aluminum frame and integration of the electrical components.

The use of solar panels as a primary energy source underscores the project's commitment to renewable energy, while the rechargeable electric lawn mower serves as a practical example of how existing technologies can be repurposed. The solar charge controller plays a critical role in managing the energy flow from the solar panels to the battery storage system, ensuring optimal charging and preventing over-discharge. The motor controller is essential for regulating the operation of the electric wheelchair motors, allowing for precise control of the device's movement and functionality.

The overall design prioritizes durability and efficiency, with the aluminum frame providing a robust structure capable of supporting the weight of the components while remaining lightweight. The estimated project cost reflects the investment in high-quality materials and components, which are crucial for the longevity and performance of the device.

In conclusion, the SCRCELM project not only serves as a viable alternative to gasoline-powered devices but also exemplifies the potential for creative solutions in the realm of renewable energy. The comprehensive video series acts as a valuable resource for individuals interested in replicating the project or gaining insights into the construction of similar devices.Create a device that did not rely on gasoline, was simple to operate, could be used as a backup energy source, and to share with others how I built the device. The how-to video series is setup very similar to my previous large project which was showing others how to build a 63W solar panel and solar powered system.

There are a total of 14 videos, including the intro video, where I explain in great detail how I created the SCRCELM. If you have any questions, please visit my FAQ page first, and if your question is not listed there, visit my contact page at: Robert-Smith. net. I put a lot of time and effort into producing these videos, so if you find them interesting or helpful, please rate, subscribe, or leave a comment.

The amount of time it took to complete this project was roughly 130 man hours. Most of the time was spent creating the aluminum frame. The next bulk of time was spent on research and development. I estimated the weight of the device to be a little over 200lbs. The total cost of the project was estimated to be a little over $1500. 00. Some of the most expensive items were the rechargeable electric lawn mower, solar panels, solar charge controller, motor controller, and electric wheelchair motors. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713

.jpg)