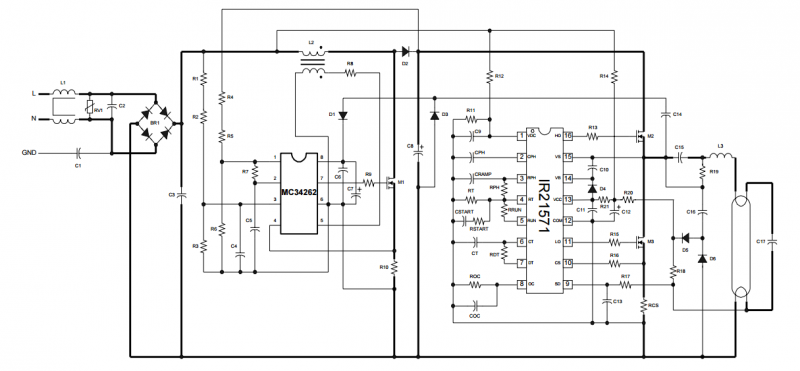

25W 230VAC small size ballast using IR2520D

The IR2520D Ballast Control IC is designed to optimize the performance of compact fluorescent lamps (CFLs) by providing a range of advanced features that enhance reliability and efficiency. This integrated circuit is characterized by its low component count, consisting of only 19 external components, which simplifies the design and reduces manufacturing costs. The IC operates with a high starting frequency, facilitating a soft start to the lamp, thereby preventing flashover and extending the lifespan of the lamp.

The adjustable preheat time feature allows for customization based on specific lamp requirements, while the adjustable run frequency enables precise control over lamp power output. This flexibility is critical in applications where varying light levels are needed. Furthermore, the IR2520D incorporates several protective measures, including fault protection for open filament conditions and failure to strike, ensuring the circuit can handle abnormal operating conditions without catastrophic failure.

The adaptive zero-voltage switching (ZV) feature enhances efficiency by minimizing switching losses, while the internal crest factor and non-zero voltage switching (ZVS) protection further improve reliability. The voltage-controlled oscillator (VCO) at the heart of the IC allows for external programming of the minimum frequency, with an analog voltage input ranging from 0-5VDC, facilitating easy integration into various applications.

The design also benefits from the use of the VS pin and the RDSon of the low-side half-bridge MOSFET for over-current protection, which eliminates the need for additional current sensing resistors. This design choice not only simplifies the circuit but also enhances its robustness against over-current conditions.

In conclusion, the IR2520D Ballast Control IC represents a significant advancement in CFL ballast technology, providing a reliable, efficient, and compact solution that meets the demands of modern lighting applications. Its features contribute to improved lamp life and performance, making it a preferred choice over traditional self-oscillating solutions. For detailed specifications and operational guidelines, consulting the IR2520D datasheet is recommended.The circuit is built around the IR2520D Ballast Control IC. The IR2520D provides adjustable preheat time, adjustable run frequency to set the lamp power, high starting frequency for soft start and to avoid lamp flash, fault protection for open filament condition and failure to strike, low AC line protection and auto-restart after line brownout conditions. The IR2520D is a low-cost solution with only 8 pins and allows the component count for the complete solution to be reduced down to 19 components.

In the CFL market, the self-oscillating bipolar transistor solution is still more popular than a ballast control IC plus FETs solution due to lower cost. This approach is very simple in nature but has disadvantages including: ! DIAC or additional circuit required for starting, additional free-wheeling diodes required ! operating frequencies determined by bi-polar tran- sistor storage time and toroid saturation (not easy to design, very dependent on tolerances in production and difficult to set the frequencies precisely), !

unreliable “always hot” PTC thermistor used for preheat that often fails in the field, ! no protection against lamp non-strike or open filaments conditions, ! no smooth frequency ramping during ignition, ! capacitive mode operations, ! high crest factor in the lamp current.

These can result in high susceptibility to components and load tolerances and/or catastrophic failure of ballast output stage components and a short lamp life. The IR2520D includes adaptive zero-voltage switching (ZV, adaptive run frequency for zero-voltage switching), internal crest factor and non-zero voltage switching (ZVS) protection, as well as an integrated bootstrap diode.

The heart of this IC is a voltage controlled oscillator (VCO) with externally programmable minimum frequency and a 0-5VDC analog voltage input.

One of the biggest advantages of the IR2520 is that it uses the VS pin and the RDSon of the low-side half-bridge MOSFET for over-current protection and to detect non-ZVS conditions. An internal 600V FET connects the VS pin to the VS sensing circuitry and allows for the VS pin to be accurately measured during the time when pin LO is high, while withstanding the high DC bus voltage during the other portion of the switching cycle when the high-side FET is turned on and VS is at the DC bus potential.

This eliminates the need for a highprecision current sensing resistor that is typically used to detect over current.

Please refer to the IR2520D datasheet for further information on the IR2520D including electrical parameters, state diagram and complete functional description. As a result of the IR2520 features, the MINIBALLAST1 circuit using the IR2520D is a complete matchbox solution that offers better reliability and longer lamp life than self oscillating solutions while reducing component count and ballast size.

🔗 External reference