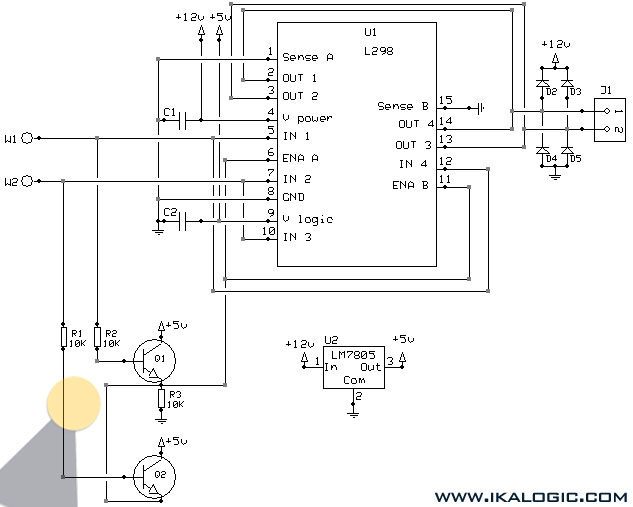

4A H-bridge motor driver using the L298 IC Schematic

This implementation utilizes the L298 integrated circuit to drive motors and inductive loads with a continuous current capacity of up to 4A. The L298 consists of two independent channels, each capable of driving loads of up to 2A. By connecting these channels in parallel, as illustrated in the schematic, a single driver capable of handling 4A is achieved. Transistors Q1 and Q2 function as an OR gate, enabling the L298 when either of the control signals W1 or W2 is high. When both W1 and W2 are low (logic 0), the driver is disabled, resulting in a high impedance state at the output, allowing any connected motor to rotate freely due to its inertia. Capacitors C1 and C2 are 10 nF decoupling capacitors, while diodes D1 to D4 serve as flyback diodes, with their forward current rated to match the expected load. The motor leads are directly connected to connector J1. The circuit operates with a power supply range of 9V to 35V. Figure 1 illustrates a PCB implementation of this circuit. An actual image of the motor drivers used in the ROBOCON 2007 competition is also provided, highlighting the secure attachment of the heat sink to the driver, which safeguards the IC from overheating due to stall currents.

The L298 motor driver circuit is designed to control the direction and speed of DC motors and other inductive loads effectively. The L298 IC is a dual H-bridge driver, allowing for bidirectional control of motors. The parallel configuration of the two channels enhances the current capacity, making it suitable for applications requiring higher power levels. The transistors Q1 and Q2 act as control switches; when either control signal W1 or W2 is activated, the corresponding channel of the L298 is enabled, allowing current to flow through the motor in the desired direction.

The decoupling capacitors C1 and C2 are critical for stabilizing the power supply voltage and filtering out high-frequency noise, ensuring smooth operation of the motor. The flyback diodes D1 to D4 are essential for protecting the circuit from voltage spikes generated when the motor is switched off, as these spikes can damage the driver. The choice of diodes should reflect the maximum current expected in the application to guarantee adequate protection.

The direct connection of the motor leads to J1 simplifies the design, allowing for easy integration into various systems. The specified operating voltage range of 9V to 35V provides flexibility for different motor specifications and application requirements. The inclusion of a heat sink is a critical design consideration, as it dissipates heat generated during operation, particularly under high load conditions, thus preventing thermal shutdown or damage to the L298 IC. The successful implementation of this circuit in the ROBOCON 2007 competition demonstrates its reliability and effectiveness in practical applications.This is an implementation of the L298 to drive motors and inductive loads up to 4A continuously. Initially the L298 contains two separate channels, each one capable of driving 2A loads. Connecting them in parallel as in the schematic makes a single 4A driver. The two transistors Q1 and Q2 act as an OR gate enabling the L298 if any of the two signa ls W1 or W2 are high. If both W1 and W2 are low (logic 0), the driver is disabled and provides a high impedance on its output, causing an eventually connected motor to move freely with its inertia. C1 and C2 are 10 nF decoupling capacitors. D1 to D4 are flyback diodes. Their forward current should correspond with the the expected load. The two leads of the motor are directly connected to J1. The circuit can be powered with 9V to 35V Here figure 1, is an implementation of this circuit on a PCB.

This an actual picture of the motor drivers we used in the ROBOCON 2007 competition. Notice how the heat sink is firmly attached to the driver. This protects the IC from eventually burning-up from stall currents. 🔗 External reference

The L298 motor driver circuit is designed to control the direction and speed of DC motors and other inductive loads effectively. The L298 IC is a dual H-bridge driver, allowing for bidirectional control of motors. The parallel configuration of the two channels enhances the current capacity, making it suitable for applications requiring higher power levels. The transistors Q1 and Q2 act as control switches; when either control signal W1 or W2 is activated, the corresponding channel of the L298 is enabled, allowing current to flow through the motor in the desired direction.

The decoupling capacitors C1 and C2 are critical for stabilizing the power supply voltage and filtering out high-frequency noise, ensuring smooth operation of the motor. The flyback diodes D1 to D4 are essential for protecting the circuit from voltage spikes generated when the motor is switched off, as these spikes can damage the driver. The choice of diodes should reflect the maximum current expected in the application to guarantee adequate protection.

The direct connection of the motor leads to J1 simplifies the design, allowing for easy integration into various systems. The specified operating voltage range of 9V to 35V provides flexibility for different motor specifications and application requirements. The inclusion of a heat sink is a critical design consideration, as it dissipates heat generated during operation, particularly under high load conditions, thus preventing thermal shutdown or damage to the L298 IC. The successful implementation of this circuit in the ROBOCON 2007 competition demonstrates its reliability and effectiveness in practical applications.This is an implementation of the L298 to drive motors and inductive loads up to 4A continuously. Initially the L298 contains two separate channels, each one capable of driving 2A loads. Connecting them in parallel as in the schematic makes a single 4A driver. The two transistors Q1 and Q2 act as an OR gate enabling the L298 if any of the two signa ls W1 or W2 are high. If both W1 and W2 are low (logic 0), the driver is disabled and provides a high impedance on its output, causing an eventually connected motor to move freely with its inertia. C1 and C2 are 10 nF decoupling capacitors. D1 to D4 are flyback diodes. Their forward current should correspond with the the expected load. The two leads of the motor are directly connected to J1. The circuit can be powered with 9V to 35V Here figure 1, is an implementation of this circuit on a PCB.

This an actual picture of the motor drivers we used in the ROBOCON 2007 competition. Notice how the heat sink is firmly attached to the driver. This protects the IC from eventually burning-up from stall currents. 🔗 External reference