Analog Tachometer Readout

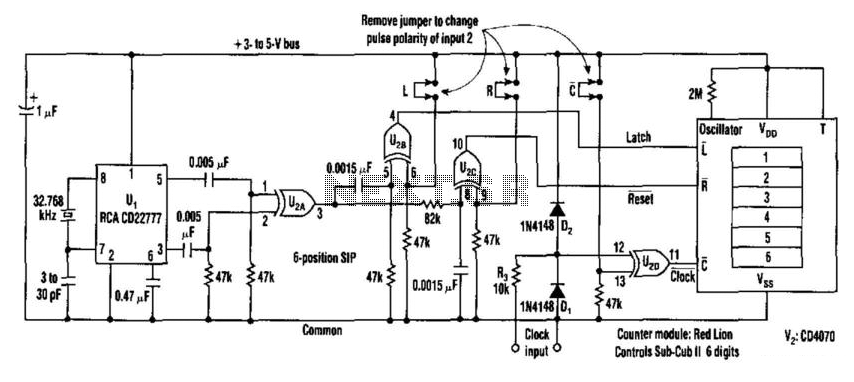

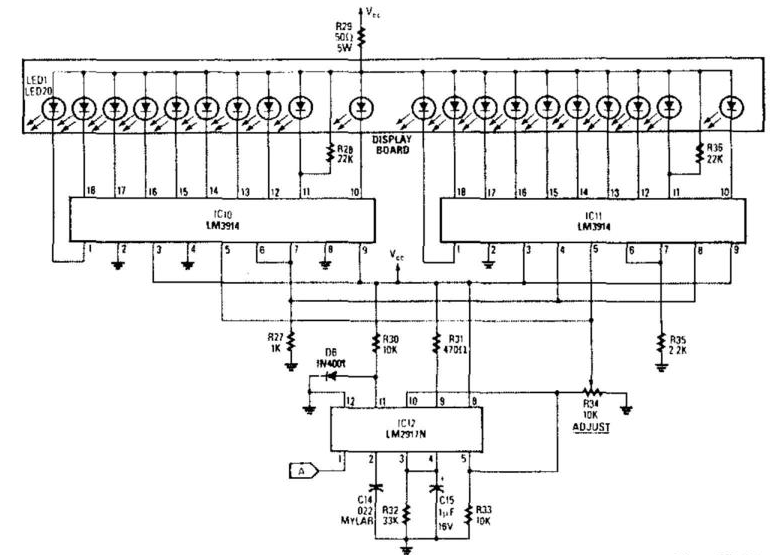

The analog display includes a frequency-to-voltage converter (IC12) along with bar-graph segment drivers IC10 and IC11. The calibration adjustment resistor R34 is configured to ensure that an engine RPM of 5,000 to 7,000 activates the first LED, which indicates the redline value.

The analog display circuit is designed to visualize engine RPM through a series of illuminated LEDs, providing real-time feedback to the operator. The frequency-to-voltage converter (IC12) takes the input frequency from the engine's tachometer signal and converts it into a proportional voltage. This conversion is crucial as it allows for a straightforward interpretation of engine speed in a visual format.

The output voltage from IC12 is fed into the bar-graph segment drivers, IC10 and IC11, which manage the illumination of the LED segments. These drivers are responsible for controlling the brightness and activation of the LEDs based on the voltage levels provided by IC12. Each segment corresponds to a specific range of RPM, allowing the operator to easily gauge engine performance.

R34 serves as the calibration adjustment resistor, enabling fine-tuning of the system to ensure accurate LED activation at the specified RPM thresholds. By adjusting R34, the system can be calibrated to light the first LED at an engine RPM of 5,000 to 7,000, marking the critical redline value. This feature is essential for performance monitoring, as it helps prevent engine over-revving and potential damage.

Overall, this analog display circuit provides a reliable means of monitoring engine RPM, utilizing a combination of frequency-to-voltage conversion and LED visualization to enhance user experience and safety.The analog display consists of a frequency/voltage converter (IC12) and bar-graph segment drivers IC10 and IC11. R34 is the calibration adjustment and is set so that an engine rpm of 5 000 to 7000 rpm lights the first LED (redline value)

🔗 External reference

The analog display circuit is designed to visualize engine RPM through a series of illuminated LEDs, providing real-time feedback to the operator. The frequency-to-voltage converter (IC12) takes the input frequency from the engine's tachometer signal and converts it into a proportional voltage. This conversion is crucial as it allows for a straightforward interpretation of engine speed in a visual format.

The output voltage from IC12 is fed into the bar-graph segment drivers, IC10 and IC11, which manage the illumination of the LED segments. These drivers are responsible for controlling the brightness and activation of the LEDs based on the voltage levels provided by IC12. Each segment corresponds to a specific range of RPM, allowing the operator to easily gauge engine performance.

R34 serves as the calibration adjustment resistor, enabling fine-tuning of the system to ensure accurate LED activation at the specified RPM thresholds. By adjusting R34, the system can be calibrated to light the first LED at an engine RPM of 5,000 to 7,000, marking the critical redline value. This feature is essential for performance monitoring, as it helps prevent engine over-revving and potential damage.

Overall, this analog display circuit provides a reliable means of monitoring engine RPM, utilizing a combination of frequency-to-voltage conversion and LED visualization to enhance user experience and safety.The analog display consists of a frequency/voltage converter (IC12) and bar-graph segment drivers IC10 and IC11. R34 is the calibration adjustment and is set so that an engine rpm of 5 000 to 7000 rpm lights the first LED (redline value)

🔗 External reference