Arduino FM radio receiver shield

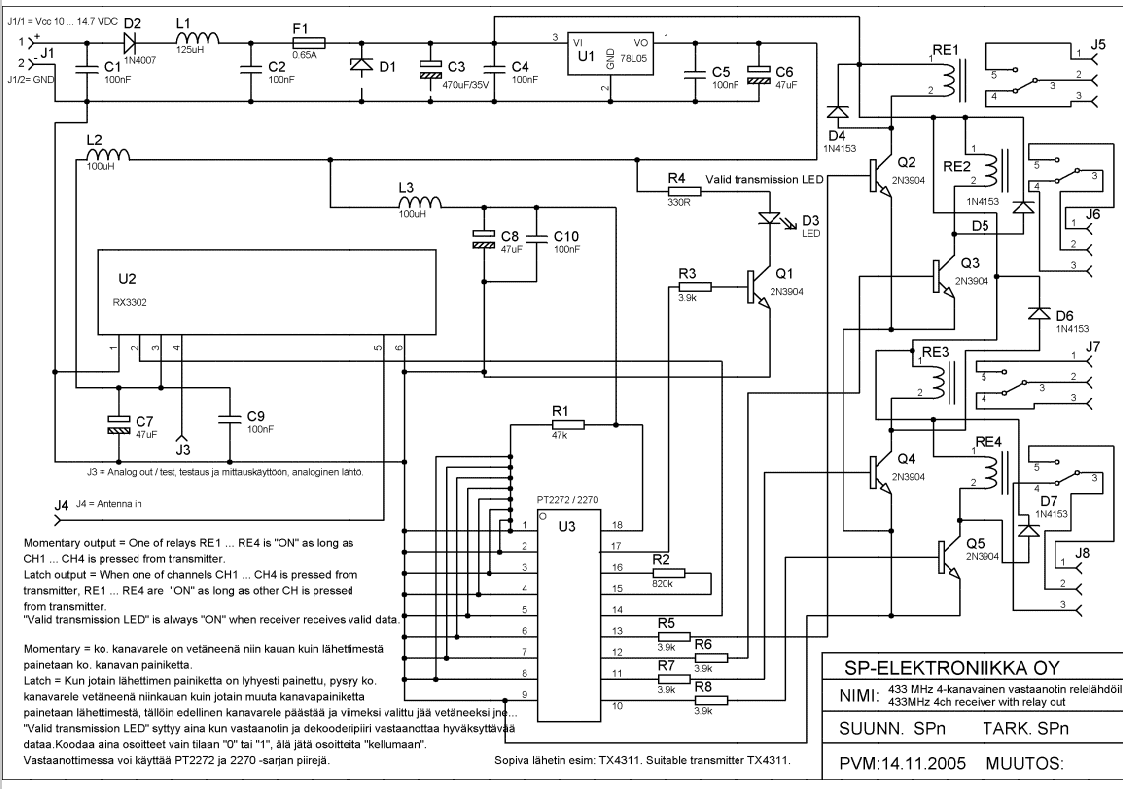

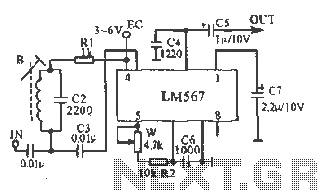

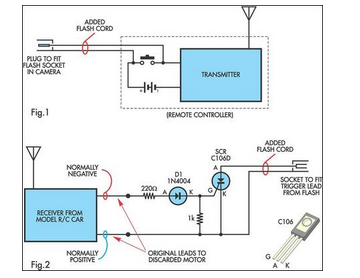

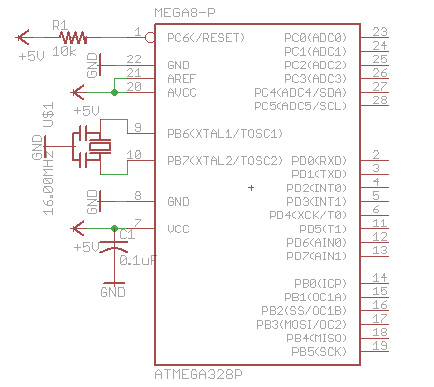

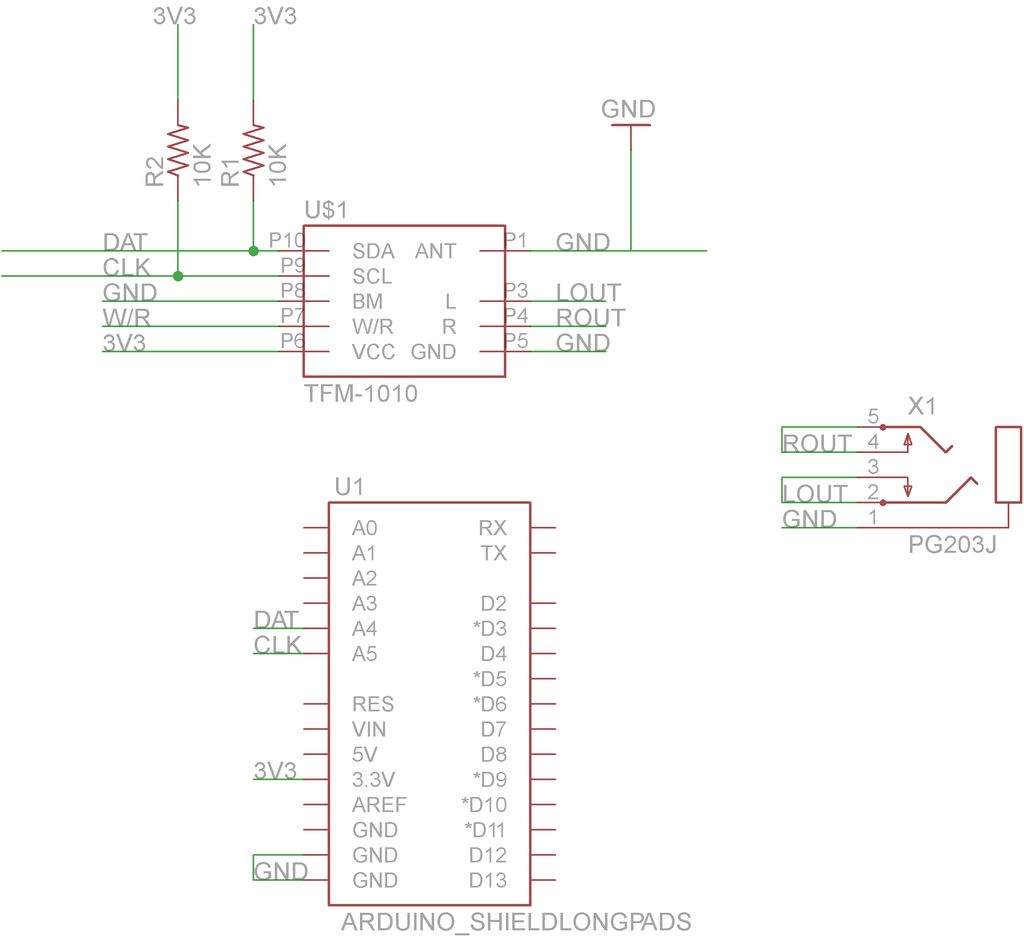

This guide will demonstrate how to construct a custom FM radio receiver shield compatible with an Arduino board. The radio chip utilized in this project is the AR1010, which can be sourced from Sparkfun or Electrokit. Code for initializing the receiver will be provided later. The shield will be fabricated using a laser cutter. The circuit design is created using Eagle software, and various resources are available for reference. It is recommended to use one-sided PCBs for ease of fabrication, with traces measuring 15 mil or wider to prevent etching issues during the laser cutting process. Once the layout is completed, it should be exported in a format suitable for laser cutting. The first image illustrates the completed PCB layout, while the second depicts the circuit schematic. To obtain a monochrome image suitable for laser cutting, the layout must be exported from Eagle as a PNG file. The relevant layers, typically the top layer and pads, should be selected. The copper PCB, available in various sizes, is commonly 160x100x1.6 mm in Sweden. After preparing the exported file in a preferred laser software, such as Illustrator, it is crucial to verify dimensions before sending it to the laser cutter. The etching settings may vary based on the laser cutter model; for example, the Marble setting is used with an Epilog 40W laser.

The FM radio receiver shield is designed to interface seamlessly with an Arduino board, allowing for versatile applications in audio projects. The AR1010 radio chip is a highly integrated solution that simplifies the process of receiving FM signals. The circuit layout should include the necessary connections for power, ground, and signal output to the Arduino's analog or digital pins, depending on the implementation.

The fabrication process begins with the design phase in Eagle, where the circuit schematic and PCB layout are created. It is essential to ensure that the design adheres to the specifications for laser cutting, particularly the trace width and the use of a single-sided PCB. The exported PNG file must maintain the correct dimensions and clarity to facilitate accurate cutting.

During the laser cutting process, the settings must be carefully adjusted based on the material used for the PCB and the capabilities of the laser cutter. The Marble setting is typically effective for etching away spray paint from the copper surface, revealing the copper traces beneath. After the etching process, the PCB can be cleaned and prepared for soldering components, including the AR1010 chip, capacitors, resistors, and connectors.

Once the components are soldered onto the PCB, the shield can be attached to the Arduino board. Programming the Arduino with the provided code will enable the FM receiver to function correctly, allowing users to tune into various FM stations. This project not only serves as a practical application of electronics and programming but also provides a hands-on experience in PCB design and fabrication.This Instructable will show you how to build your own FM radio receiver shield to be used with an Arduino board. The radio chip we are going to be using is the AR1010 on a breakoutboard found at Sparkfun or Electrokit and there will be code to get you up and running provided later on.

We are going to use an laser cutter for the shield fabrication. F irst we build up our circuit using eagle. There are many Instructables out there on how to do it such as this or this. You can download my eagle files I have been using when building this board below. Things to consider is that when you are going to be using the laser cutter for doing pcbs you have to remeber that it is one sided pcbs that is be far easiest and also that the traces has to be 15 mil or wider otherwise the laser and etching process might etch them away. Once you have your layout done it is time to export it to a more laser friendly format. The first picture below is the finished pcb layout and the second is the schematic of the circuit. To get the nice monochrome laser friendly picture (pic 3 below) you have to export it from eagle as png.

1. Select the layers that you are interest in laser cutting. I tend to only select the top layer and the pads since there residesnearlyalways all thenecessaryinformation. Next thing to do is to prepare the copper pcb. This can be found in many sizes and the one I have hear is 160x100x1, 6 mm and is pretty standard her in Sweden.

Put the exported file into yourfavoritelaser program, in this case Illustrator, and make sure that the size is correct and everything is looking fine. After that it is time to send it to the laser. The settings I use to etch the spraypaint away is the Marble setting on my Epilog 40 w laser. This will change depending on your laser type. 🔗 External reference

The FM radio receiver shield is designed to interface seamlessly with an Arduino board, allowing for versatile applications in audio projects. The AR1010 radio chip is a highly integrated solution that simplifies the process of receiving FM signals. The circuit layout should include the necessary connections for power, ground, and signal output to the Arduino's analog or digital pins, depending on the implementation.

The fabrication process begins with the design phase in Eagle, where the circuit schematic and PCB layout are created. It is essential to ensure that the design adheres to the specifications for laser cutting, particularly the trace width and the use of a single-sided PCB. The exported PNG file must maintain the correct dimensions and clarity to facilitate accurate cutting.

During the laser cutting process, the settings must be carefully adjusted based on the material used for the PCB and the capabilities of the laser cutter. The Marble setting is typically effective for etching away spray paint from the copper surface, revealing the copper traces beneath. After the etching process, the PCB can be cleaned and prepared for soldering components, including the AR1010 chip, capacitors, resistors, and connectors.

Once the components are soldered onto the PCB, the shield can be attached to the Arduino board. Programming the Arduino with the provided code will enable the FM receiver to function correctly, allowing users to tune into various FM stations. This project not only serves as a practical application of electronics and programming but also provides a hands-on experience in PCB design and fabrication.This Instructable will show you how to build your own FM radio receiver shield to be used with an Arduino board. The radio chip we are going to be using is the AR1010 on a breakoutboard found at Sparkfun or Electrokit and there will be code to get you up and running provided later on.

We are going to use an laser cutter for the shield fabrication. F irst we build up our circuit using eagle. There are many Instructables out there on how to do it such as this or this. You can download my eagle files I have been using when building this board below. Things to consider is that when you are going to be using the laser cutter for doing pcbs you have to remeber that it is one sided pcbs that is be far easiest and also that the traces has to be 15 mil or wider otherwise the laser and etching process might etch them away. Once you have your layout done it is time to export it to a more laser friendly format. The first picture below is the finished pcb layout and the second is the schematic of the circuit. To get the nice monochrome laser friendly picture (pic 3 below) you have to export it from eagle as png.

1. Select the layers that you are interest in laser cutting. I tend to only select the top layer and the pads since there residesnearlyalways all thenecessaryinformation. Next thing to do is to prepare the copper pcb. This can be found in many sizes and the one I have hear is 160x100x1, 6 mm and is pretty standard her in Sweden.

Put the exported file into yourfavoritelaser program, in this case Illustrator, and make sure that the size is correct and everything is looking fine. After that it is time to send it to the laser. The settings I use to etch the spraypaint away is the Marble setting on my Epilog 40 w laser. This will change depending on your laser type. 🔗 External reference