Arduino Motor Knob

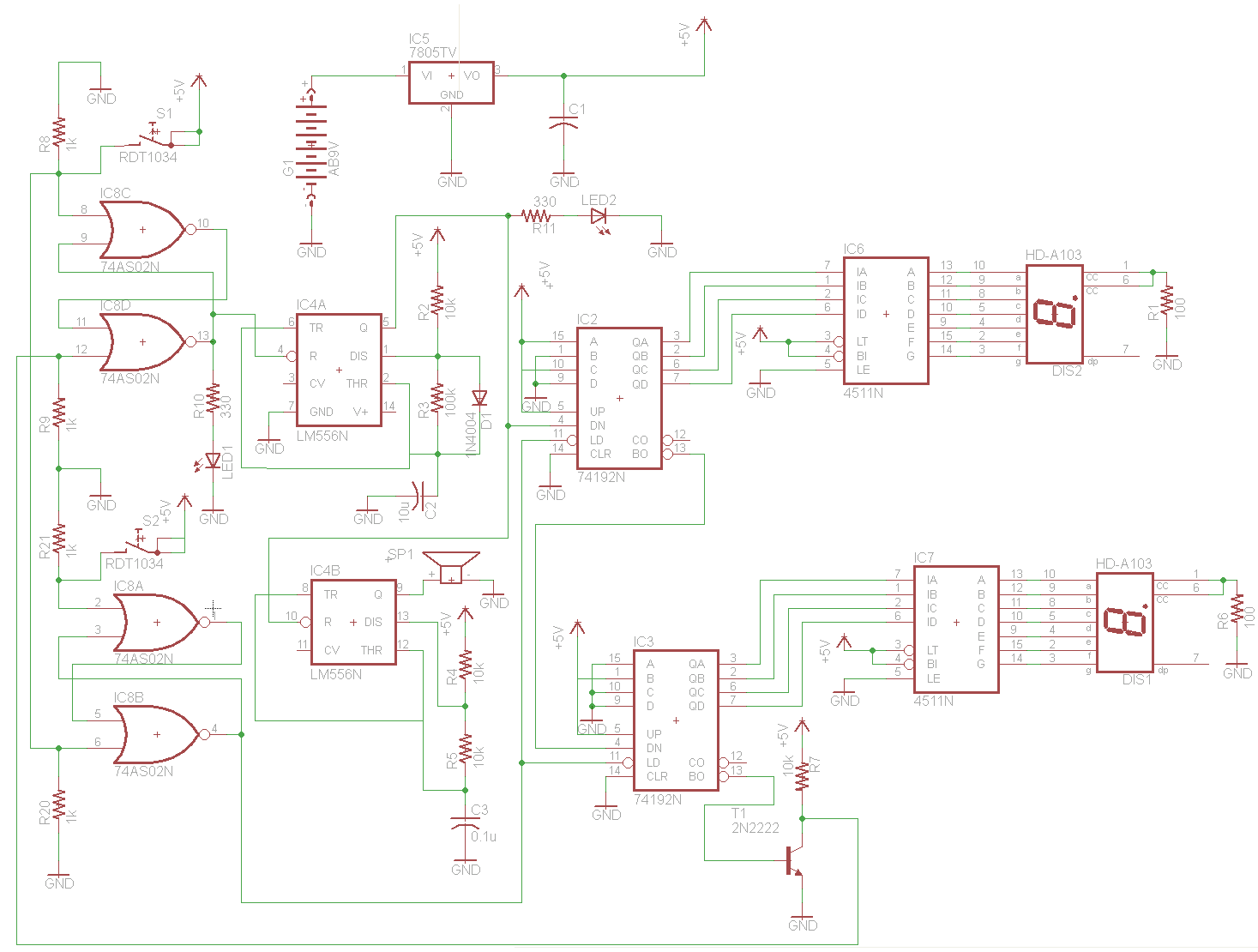

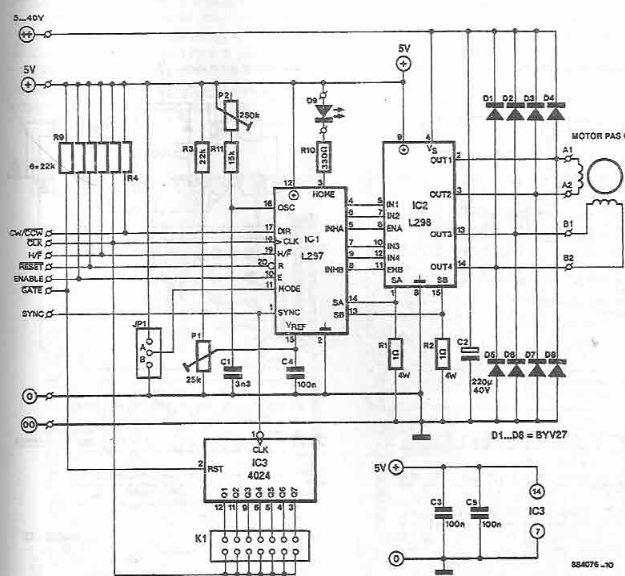

Stepper motors, because of their distinct design, can be operated with a high level of precision without the need for feedback mechanisms. The shaft of a stepper motor, equipped with a series of magnets, is governed by a set of electromagnetic coils that are energized in a specific sequence, allowing for precise forward or backward movement in small increments known as "steps." There are two main types of stepper motors: Unipolar and Bipolar, and it is crucial to identify which type is being used, as each requires a different circuit configuration. The provided example code is capable of controlling both types of motors. Refer to the schematics for unipolar and bipolar motors for guidance on wiring. In this example, a potentiometer or another sensor connected to analog input 0 is utilized to regulate the movement of the stepper motor through the Arduino Stepper Library. The stepper motor is controlled using digital pins 8, 9, 10, and 11, applicable to both unipolar and bipolar motors.

Stepper motors are widely utilized in applications requiring precise positioning and control, such as 3D printers, CNC machines, and robotics. The operation of a stepper motor is based on the principle of electromagnetic induction, where the coils create magnetic fields that interact with the permanent magnets on the rotor. When the coils are energized in a specific sequence, the rotor aligns itself with the magnetic field, resulting in incremental movement.

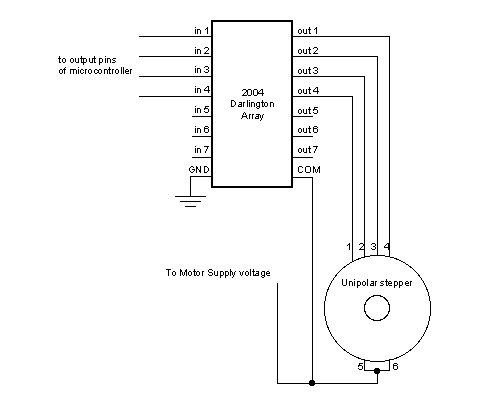

The two primary types of stepper motors differ in their construction and operation. Unipolar stepper motors have a center-tapped winding for each phase, allowing for simpler control but typically resulting in lower torque compared to bipolar motors. Bipolar stepper motors, on the other hand, utilize a more complex winding arrangement, allowing for higher torque and efficiency but requiring more intricate control circuitry.

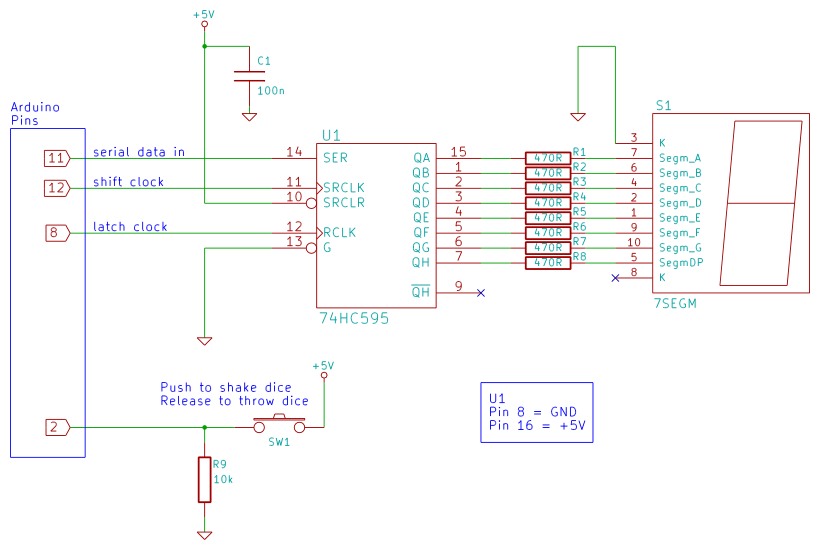

The circuit design for controlling stepper motors involves connecting the motor coils to a microcontroller, such as an Arduino. The microcontroller sends signals through designated digital pins, which energize the coils in the correct sequence to achieve the desired movement. In the provided example, pins 8, 9, 10, and 11 are utilized for this purpose. The potentiometer connected to analog input 0 serves as a variable resistor, allowing the user to adjust the speed and direction of the motor by altering the input voltage.

To implement this control system, careful attention must be paid to the power requirements and specifications of the stepper motor in use. Proper power supply and driver circuits are essential to ensure reliable operation and prevent damage to the motor or control circuitry. Additionally, understanding the step angle of the motor is crucial for achieving the desired resolution in positioning.

Overall, the integration of stepper motors with microcontrollers provides a powerful solution for applications requiring precise control of movement, making them an essential component in modern electronic designs.Stepper motors, due to their unique design, can be controlled to a high degree of accuracy without any feedback mechanisms. The shaft of a stepper, mounted with a series of magnets, is controlled by a series of electromagnetic coils that are charged positively and negatively in a specific sequence, precisely moving it forward or backward in small

"steps". There are two types of steppers, Unipolars and Bipolars, and it is very important to know which type you are working with. For each of the motors, there is a different circuit. The example code will control both kinds of motors. See the unipolar and bipolar motor schematics for information on how to wire up your motor. In this example, a potentiometer (or other sensor) on analog input 0 is used to control the movement of a stepper motor using the Arduino Stepper Library.

The stepper is controlled by with digital pins 8, 9, 10, and 11 for either unipolar or bipolar motors. 🔗 External reference

Stepper motors are widely utilized in applications requiring precise positioning and control, such as 3D printers, CNC machines, and robotics. The operation of a stepper motor is based on the principle of electromagnetic induction, where the coils create magnetic fields that interact with the permanent magnets on the rotor. When the coils are energized in a specific sequence, the rotor aligns itself with the magnetic field, resulting in incremental movement.

The two primary types of stepper motors differ in their construction and operation. Unipolar stepper motors have a center-tapped winding for each phase, allowing for simpler control but typically resulting in lower torque compared to bipolar motors. Bipolar stepper motors, on the other hand, utilize a more complex winding arrangement, allowing for higher torque and efficiency but requiring more intricate control circuitry.

The circuit design for controlling stepper motors involves connecting the motor coils to a microcontroller, such as an Arduino. The microcontroller sends signals through designated digital pins, which energize the coils in the correct sequence to achieve the desired movement. In the provided example, pins 8, 9, 10, and 11 are utilized for this purpose. The potentiometer connected to analog input 0 serves as a variable resistor, allowing the user to adjust the speed and direction of the motor by altering the input voltage.

To implement this control system, careful attention must be paid to the power requirements and specifications of the stepper motor in use. Proper power supply and driver circuits are essential to ensure reliable operation and prevent damage to the motor or control circuitry. Additionally, understanding the step angle of the motor is crucial for achieving the desired resolution in positioning.

Overall, the integration of stepper motors with microcontrollers provides a powerful solution for applications requiring precise control of movement, making them an essential component in modern electronic designs.Stepper motors, due to their unique design, can be controlled to a high degree of accuracy without any feedback mechanisms. The shaft of a stepper, mounted with a series of magnets, is controlled by a series of electromagnetic coils that are charged positively and negatively in a specific sequence, precisely moving it forward or backward in small

"steps". There are two types of steppers, Unipolars and Bipolars, and it is very important to know which type you are working with. For each of the motors, there is a different circuit. The example code will control both kinds of motors. See the unipolar and bipolar motor schematics for information on how to wire up your motor. In this example, a potentiometer (or other sensor) on analog input 0 is used to control the movement of a stepper motor using the Arduino Stepper Library.

The stepper is controlled by with digital pins 8, 9, 10, and 11 for either unipolar or bipolar motors. 🔗 External reference