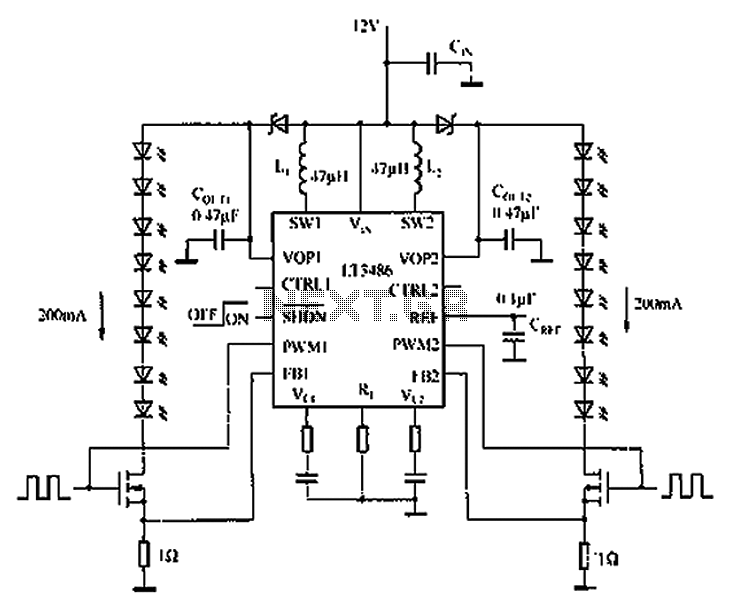

Automotive LED driver circuit diagram LT3486

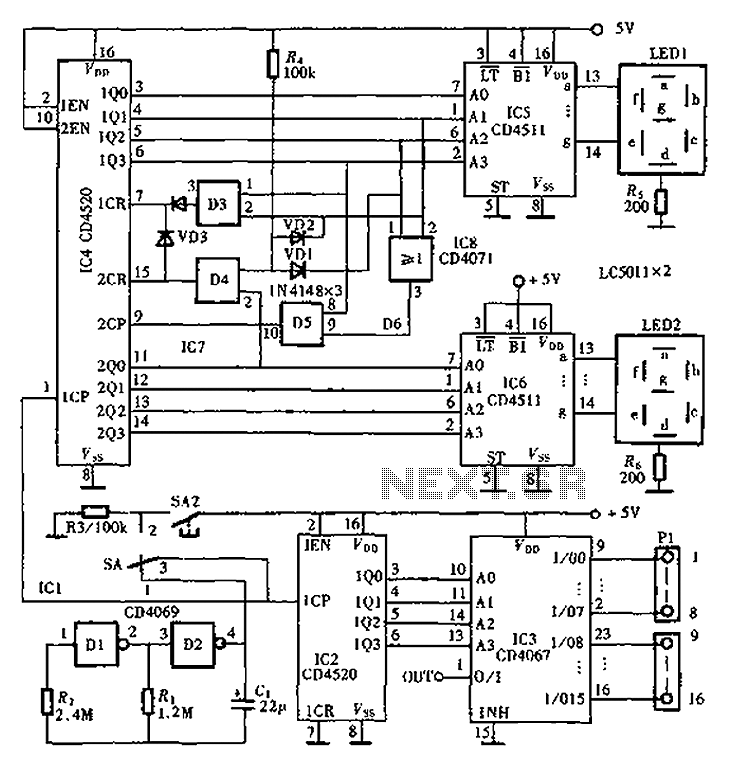

The automotive LED driver circuit diagram utilizes the LT3486. The LED is employed in the car's central high-mounted stop lamp (CHMSL), providing advantages such as faster achievement of the set brightness, higher efficiency, longer lifespan, and simplified design and installation due to the compact red LED arrays. The LED can reach the desired brightness in less than 1 millisecond, allowing drivers of vehicles behind to see the brake lights more quickly, thereby reducing the likelihood of rear-end collisions. In contrast, traditional incandescent bulbs require up to 200 milliseconds to achieve full brightness. Compared to incandescent lamps, LED lights can reduce power consumption by up to 80%, consequently lowering the vehicle's fuel consumption. To optimize the performance and lifespan of the brake LED applications, it is essential to align with automotive braking system requirements and optimize the design of the red LED string drive. The LT3486 is specifically designed for such vehicle applications. It is a dual step-up DC/DC converter, and its LED drive circuit can operate from a 12 to 14V car bus, providing a constant current drive for up to 16 LEDs (with eight transducers connected in series). Connecting LEDs in series ensures uniform brightness due to the same LED current. If needed, two separate asymmetric inverters can drive the LED strings. Dimming of the two LED strings can be independently controlled through their respective CTRL pins by utilizing an internal PWM dimming system, allowing for a dimming range of 1000 to 1. The LT3486's operating frequency can be set using an external resistor, ranging from 200 kHz to 2 MHz. Its current detection circuit features a low feedback voltage of 200 mV, which minimizes power consumption of the current-sense resistor and enhances circuit efficiency, along with an output voltage limiting function for open-circuit LED conditions.

The LT3486 automotive LED driver circuit is designed to enhance the performance of LED lighting in vehicles, particularly for the central high-mounted stop lamp (CHMSL). This circuit leverages the rapid response time of LEDs, achieving full brightness in under 1 millisecond, which significantly improves visibility for following drivers compared to traditional incandescent bulbs. The efficiency of the LT3486 allows for substantial reductions in power consumption, which translates to lower fuel usage in vehicles, making it an environmentally friendly option.

The architecture of the LT3486 includes a dual step-up DC/DC converter that can effectively manage the voltage requirements of LED arrays. It is capable of driving up to 16 LEDs in series, ensuring uniform brightness across the array. The ability to connect LEDs in series allows for consistent current flow, which is critical for maintaining the operational integrity and longevity of the LEDs.

The circuit's dimming capabilities are particularly noteworthy. The independent control of two LED strings through CTRL pins enables versatile lighting scenarios, which can be particularly useful in various driving conditions. The internal PWM dimming system allows for a wide dimming range, enhancing the adaptability of the lighting system to different environments and preferences.

Furthermore, the LT3486's design includes a low feedback voltage current detection circuit, which minimizes losses associated with current sensing. This design choice not only improves the overall efficiency of the circuit but also contributes to the longevity of the components involved. The inclusion of an output voltage limiting feature protects the LEDs from potential damage due to open-circuit conditions, ensuring reliable operation over time.

In summary, the LT3486 automotive LED driver circuit represents a significant advancement in vehicle lighting technology, combining efficiency, rapid response, and robust performance tailored to meet the demanding requirements of modern automotive applications. As shown in the automotive LED driver circuit diagram LT3486 constituted. LED used in the cars central brake light (CHMSL) when there is an advantage: faster reach the set brig htness, higher efficiency, longer life, and the very small red LED arrays easier design and installation; LED in less than 1ms of time you can reach the set brightness, so that the driver of the car behind can see the brake lights more quickly, thus reducing rear-end accidents. In contrast, the traditional light bulb takes up to 200ms of time to reach the set brightness. Compared with incandescent lamps, LED lights power consumption can be reduced up to 80%, thereby reducing the fuel consumption of the car.

To maximize the performance of the brakes LED applications and extend its life, should be combined with requirements of automotive braking systems, optimization red LED string drive design. LT3486 is designed for this type of vehicle applications and development. LT3486 is a dual step-up DC/DC converter, its LED drive circuit as shown, after a specially designed, it can be used from 12 ~ 14V car bus constant current drive up to 16 LED (per eight transducers can be connected in series).

LED can be connected in series to have the same LED current, resulting in uniform brightness. If desired, two separate asymmetric inverter is capable of driving LED strings. Dimming of the two LED strings through their respective CTRL pins independently controlled internal PWM dimming system by providing PWM signal to the respective PWM pins, thereby expanding the dimming range to 1000 to 1. LT3486 operating frequency can be set with an external resistor, the range of 200kHz ~ 2MHz. Its current detection circuit has a low feedback voltage (200mV), to reduce the current-sense resistor power consumption and improve the efficiency of the circuit, and an output voltage limiting function LED open circuit.

The LT3486 automotive LED driver circuit is designed to enhance the performance of LED lighting in vehicles, particularly for the central high-mounted stop lamp (CHMSL). This circuit leverages the rapid response time of LEDs, achieving full brightness in under 1 millisecond, which significantly improves visibility for following drivers compared to traditional incandescent bulbs. The efficiency of the LT3486 allows for substantial reductions in power consumption, which translates to lower fuel usage in vehicles, making it an environmentally friendly option.

The architecture of the LT3486 includes a dual step-up DC/DC converter that can effectively manage the voltage requirements of LED arrays. It is capable of driving up to 16 LEDs in series, ensuring uniform brightness across the array. The ability to connect LEDs in series allows for consistent current flow, which is critical for maintaining the operational integrity and longevity of the LEDs.

The circuit's dimming capabilities are particularly noteworthy. The independent control of two LED strings through CTRL pins enables versatile lighting scenarios, which can be particularly useful in various driving conditions. The internal PWM dimming system allows for a wide dimming range, enhancing the adaptability of the lighting system to different environments and preferences.

Furthermore, the LT3486's design includes a low feedback voltage current detection circuit, which minimizes losses associated with current sensing. This design choice not only improves the overall efficiency of the circuit but also contributes to the longevity of the components involved. The inclusion of an output voltage limiting feature protects the LEDs from potential damage due to open-circuit conditions, ensuring reliable operation over time.

In summary, the LT3486 automotive LED driver circuit represents a significant advancement in vehicle lighting technology, combining efficiency, rapid response, and robust performance tailored to meet the demanding requirements of modern automotive applications. As shown in the automotive LED driver circuit diagram LT3486 constituted. LED used in the cars central brake light (CHMSL) when there is an advantage: faster reach the set brig htness, higher efficiency, longer life, and the very small red LED arrays easier design and installation; LED in less than 1ms of time you can reach the set brightness, so that the driver of the car behind can see the brake lights more quickly, thus reducing rear-end accidents. In contrast, the traditional light bulb takes up to 200ms of time to reach the set brightness. Compared with incandescent lamps, LED lights power consumption can be reduced up to 80%, thereby reducing the fuel consumption of the car.

To maximize the performance of the brakes LED applications and extend its life, should be combined with requirements of automotive braking systems, optimization red LED string drive design. LT3486 is designed for this type of vehicle applications and development. LT3486 is a dual step-up DC/DC converter, its LED drive circuit as shown, after a specially designed, it can be used from 12 ~ 14V car bus constant current drive up to 16 LED (per eight transducers can be connected in series).

LED can be connected in series to have the same LED current, resulting in uniform brightness. If desired, two separate asymmetric inverter is capable of driving LED strings. Dimming of the two LED strings through their respective CTRL pins independently controlled internal PWM dimming system by providing PWM signal to the respective PWM pins, thereby expanding the dimming range to 1000 to 1. LT3486 operating frequency can be set with an external resistor, the range of 200kHz ~ 2MHz. Its current detection circuit has a low feedback voltage (200mV), to reduce the current-sense resistor power consumption and improve the efficiency of the circuit, and an output voltage limiting function LED open circuit.