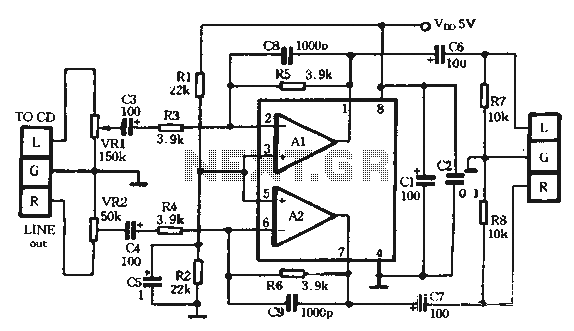

Based CNC programming gain instrumentation amplifier PGA202 203 schematic

Based on the CNC programming, a gain instrumentation amplifier circuit diagram utilizing the PGA202/203 is presented.

The PGA202/203 series of programmable gain amplifiers are designed for high-performance applications requiring precise signal amplification. These integrated circuits offer a wide range of programmable gains, typically from 1 to 1000, making them suitable for various sensor signal conditioning tasks in CNC systems.

The circuit diagram for the PGA202/203 involves the following key components:

1. **Power Supply**: The amplifier requires a dual power supply, typically ±5V to ±15V, to allow for proper signal amplification without clipping.

2. **Input Stage**: The input stage consists of differential inputs (V1 and V2), which are connected to the source of the signal to be amplified. This configuration helps in rejecting common-mode signals, thereby enhancing the accuracy of the measurement.

3. **Gain Setting Resistors**: The gain of the PGA202/203 can be adjusted using external resistors connected to the gain pins. These resistors set the feedback loop, determining the overall gain of the amplifier. The gain can be programmed through a digital interface in some configurations, allowing for dynamic adjustments based on the application requirements.

4. **Output Stage**: The output of the PGA202/203 is a single-ended output that provides the amplified signal. This output can drive further processing stages or be connected to an analog-to-digital converter (ADC) for digitization.

5. **Filtering**: It is often beneficial to include low-pass filters at the input and output stages to minimize noise and enhance the signal integrity, particularly in high-frequency applications.

6. **PCB Layout Considerations**: Careful attention should be paid to the PCB layout to minimize parasitic capacitance and inductance, which can adversely affect the performance of the amplifier. Proper grounding and power supply decoupling are essential to maintain stability and reduce noise.

Overall, the PGA202/203 instrumentation amplifier circuit is a versatile solution for amplifying low-level signals in CNC applications, providing high accuracy and flexibility in gain settings. Based CNC programming gain instrumentation amplifier PGA202/203 circuit diagram as follows:

The PGA202/203 series of programmable gain amplifiers are designed for high-performance applications requiring precise signal amplification. These integrated circuits offer a wide range of programmable gains, typically from 1 to 1000, making them suitable for various sensor signal conditioning tasks in CNC systems.

The circuit diagram for the PGA202/203 involves the following key components:

1. **Power Supply**: The amplifier requires a dual power supply, typically ±5V to ±15V, to allow for proper signal amplification without clipping.

2. **Input Stage**: The input stage consists of differential inputs (V1 and V2), which are connected to the source of the signal to be amplified. This configuration helps in rejecting common-mode signals, thereby enhancing the accuracy of the measurement.

3. **Gain Setting Resistors**: The gain of the PGA202/203 can be adjusted using external resistors connected to the gain pins. These resistors set the feedback loop, determining the overall gain of the amplifier. The gain can be programmed through a digital interface in some configurations, allowing for dynamic adjustments based on the application requirements.

4. **Output Stage**: The output of the PGA202/203 is a single-ended output that provides the amplified signal. This output can drive further processing stages or be connected to an analog-to-digital converter (ADC) for digitization.

5. **Filtering**: It is often beneficial to include low-pass filters at the input and output stages to minimize noise and enhance the signal integrity, particularly in high-frequency applications.

6. **PCB Layout Considerations**: Careful attention should be paid to the PCB layout to minimize parasitic capacitance and inductance, which can adversely affect the performance of the amplifier. Proper grounding and power supply decoupling are essential to maintain stability and reduce noise.

Overall, the PGA202/203 instrumentation amplifier circuit is a versatile solution for amplifying low-level signals in CNC applications, providing high accuracy and flexibility in gain settings. Based CNC programming gain instrumentation amplifier PGA202/203 circuit diagram as follows: