Battery charger and PSU

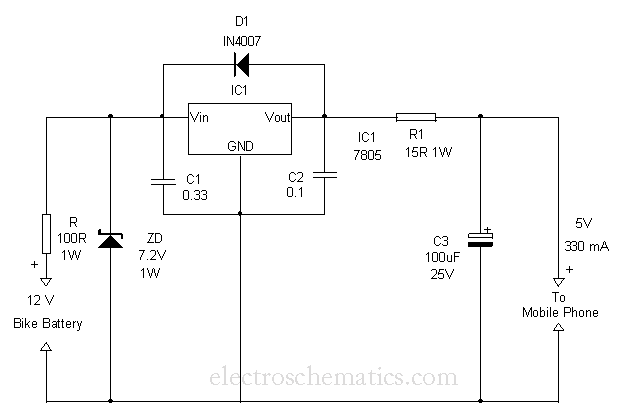

This circuit was created for digital cameras. It's known the digital cameras have considerable power consumption. For example, my camera Minolta E223 requires approximately 800 mA. In practice, a mains power supply or high capacity NiMH accumulators (batteries) can satisfy this demand. This circuit consists of two parts, charger and adapter. The transformer, rectifier bridge, and buffer capacitor are common. The adapter is quite simple; its main part is an adjustable voltage regulator LM317 according to usual setting. Output is suitable for camera jack plug. Voltage can be adjusted in the range of 2-9 V. In the charger circuit, a 7805 fixed voltage regulator works as a current generator to assure constant current during charging. This charging current can be adjusted with the 100/1W potentiometer in the range of about 50-300 mA, indicated by a small current measuring instrument. From one to four batteries can be charged simultaneously. The switch must be set according to the number of batteries, and the charging current of batteries given by the manufacturer must be adjusted. This circuit doesn't measure charging time and charging condition of batteries. Manufacturers give charging time, usually 14-16 h. This problem is solved with a simple, cheap mechanical mains timer, which is sufficiently accurate.

The circuit designed for charging and powering digital cameras incorporates two main components: a charger and an adapter. The adapter utilizes a transformer to step down the mains voltage, which is then rectified by a bridge rectifier to convert the AC to DC. A buffer capacitor smooths out the rectified voltage to provide a stable DC output. The adjustable voltage regulator LM317 is employed to provide a variable output voltage suitable for the camera, adjustable within the range of 2 to 9 volts, depending on the specific requirements of the camera model being used.

In the charger section, a 7805 fixed voltage regulator functions as a current generator, ensuring a constant current flow during the battery charging process. The charging current can be finely tuned using a 100-ohm, 1-watt potentiometer, allowing for adjustments between 50 mA and 300 mA. This is crucial for accommodating different battery types and their specific charging requirements. A small current measuring instrument is included in the circuit to provide real-time feedback on the charging current, enhancing usability.

The design allows for the simultaneous charging of one to four NiMH batteries. A switch is incorporated to select the number of batteries being charged, which is essential to ensure the charging current is appropriately adjusted in accordance with the specifications provided by the battery manufacturer. Notably, the circuit does not include a mechanism for monitoring the charging time or the condition of the batteries. Instead, the manufacturer-recommended charging time, typically ranging from 14 to 16 hours, is adhered to. To address the lack of a built-in timer, a mechanical mains timer is integrated into the system, allowing for automated control of the charging duration while remaining cost-effective and straightforward in design. This approach provides a practical solution for users needing to charge batteries for digital cameras efficiently.This circuit was created for digital cameras. It's known the digital cameras have considerable power consumption. For example my camera Minolta E223 requires approximately 800 mA. In practice a mains power supply or high capacity NiMH accumulators (batteries) can satisfy this demand. This circuit consists of two parts, charger and adapter. The transformer, rectifier bridge and buffer condensator are common. Adapter is quite simply its main part is an adjustable voltage regulator LM 317 according to usual setting.

Output is a suitable for camera jack plug. Voltage can be adjusted in range 2-9 V. In the charger circuit a 7805 fixed voltage regulator works as current generator assured constant current during charging. This charging current can be adjusted with the 100 /1W potentiometer in range about 50-300 mA indicated by a small current measuring instrument.

From one to four batteries can be charged simultaneously. The switch must be set according to number of batteries, and charging current of batteries given by manufacturer must be adjusted. This circuit doesn't measure charging time and charging condition of batteries. Manufacturers give charging time, usually 14-16 h. I solved this problem with a simply, cheap mechanical mains timer. I think its accuracy is sufficient. 🔗 External reference

The circuit designed for charging and powering digital cameras incorporates two main components: a charger and an adapter. The adapter utilizes a transformer to step down the mains voltage, which is then rectified by a bridge rectifier to convert the AC to DC. A buffer capacitor smooths out the rectified voltage to provide a stable DC output. The adjustable voltage regulator LM317 is employed to provide a variable output voltage suitable for the camera, adjustable within the range of 2 to 9 volts, depending on the specific requirements of the camera model being used.

In the charger section, a 7805 fixed voltage regulator functions as a current generator, ensuring a constant current flow during the battery charging process. The charging current can be finely tuned using a 100-ohm, 1-watt potentiometer, allowing for adjustments between 50 mA and 300 mA. This is crucial for accommodating different battery types and their specific charging requirements. A small current measuring instrument is included in the circuit to provide real-time feedback on the charging current, enhancing usability.

The design allows for the simultaneous charging of one to four NiMH batteries. A switch is incorporated to select the number of batteries being charged, which is essential to ensure the charging current is appropriately adjusted in accordance with the specifications provided by the battery manufacturer. Notably, the circuit does not include a mechanism for monitoring the charging time or the condition of the batteries. Instead, the manufacturer-recommended charging time, typically ranging from 14 to 16 hours, is adhered to. To address the lack of a built-in timer, a mechanical mains timer is integrated into the system, allowing for automated control of the charging duration while remaining cost-effective and straightforward in design. This approach provides a practical solution for users needing to charge batteries for digital cameras efficiently.This circuit was created for digital cameras. It's known the digital cameras have considerable power consumption. For example my camera Minolta E223 requires approximately 800 mA. In practice a mains power supply or high capacity NiMH accumulators (batteries) can satisfy this demand. This circuit consists of two parts, charger and adapter. The transformer, rectifier bridge and buffer condensator are common. Adapter is quite simply its main part is an adjustable voltage regulator LM 317 according to usual setting.

Output is a suitable for camera jack plug. Voltage can be adjusted in range 2-9 V. In the charger circuit a 7805 fixed voltage regulator works as current generator assured constant current during charging. This charging current can be adjusted with the 100 /1W potentiometer in range about 50-300 mA indicated by a small current measuring instrument.

From one to four batteries can be charged simultaneously. The switch must be set according to number of batteries, and charging current of batteries given by manufacturer must be adjusted. This circuit doesn't measure charging time and charging condition of batteries. Manufacturers give charging time, usually 14-16 h. I solved this problem with a simply, cheap mechanical mains timer. I think its accuracy is sufficient. 🔗 External reference