battery desulphation progress

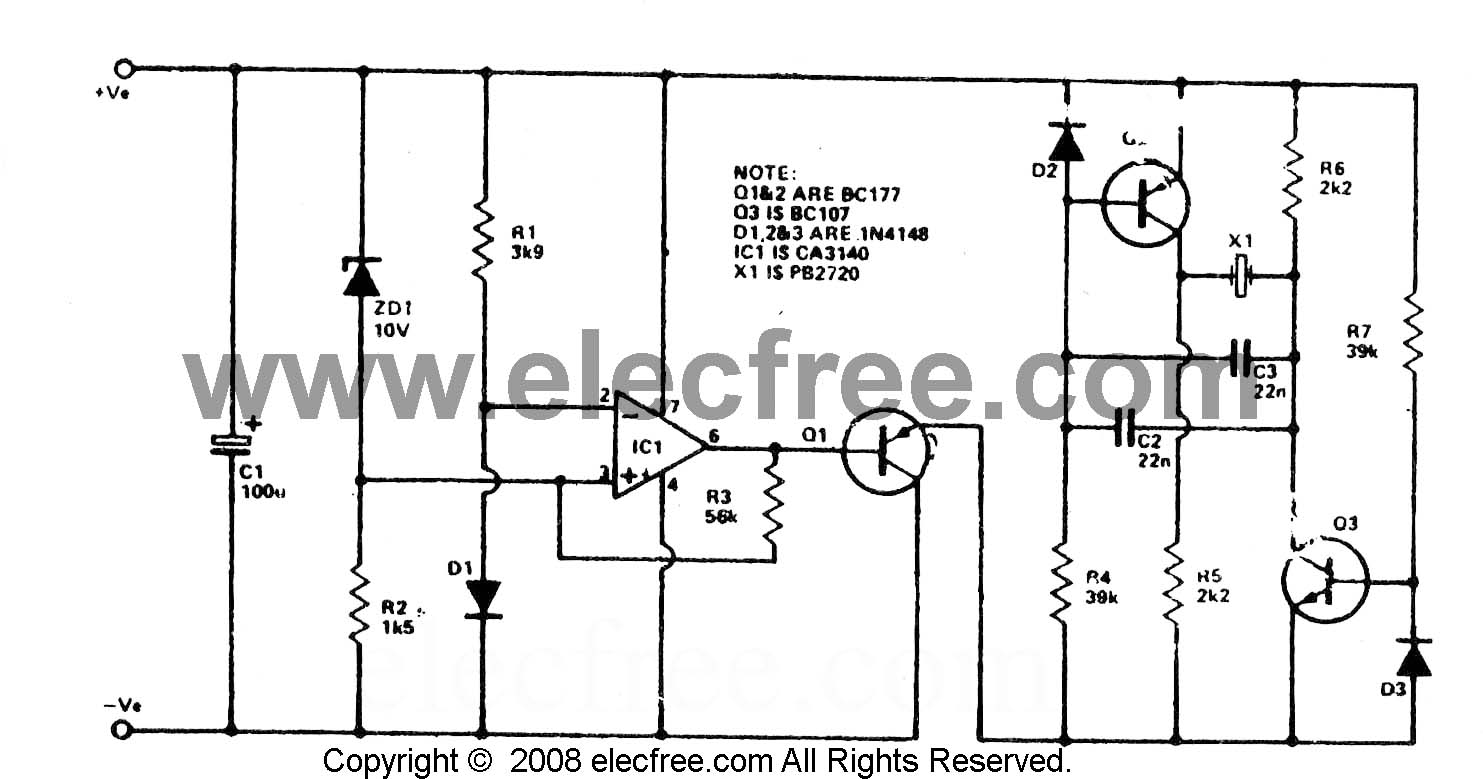

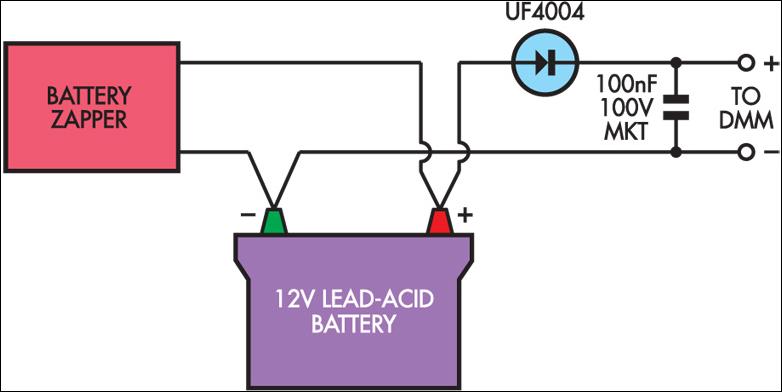

Several readers have inquired about how to determine when the Lead-Acid Battery Zapper has effectively completed the desulphation process. Based on the author's experience, batteries that are responsive to this treatment typically exhibit a notably high peak voltage across their terminals at the onset of the process. If this voltage gradually diminishes and nearly vanishes, it indicates that the treatment is nearing completion. The duration for this process can vary significantly, ranging from a week to several months, depending on the battery's size and condition. In cases where an oscilloscope is unavailable for monitoring voltage peaks, a simple peak detector can be assembled using a fast diode and a 100nF capacitor. A high-impedance multimeter, such as most digital types, can then be employed to measure the average DC voltage across the capacitor.

The Lead-Acid Battery Zapper is a device designed to restore the capacity of lead-acid batteries through a process known as desulphation. During this process, sulfation—a common issue where lead sulfate crystals build up on the battery plates—can be reversed. The initial high peak voltage observed at the terminals serves as an indicator of the battery's state prior to treatment. As the desulphation progresses, the steady decline in peak voltage reflects the reduction of sulfation, ultimately leading to improved battery performance.

To construct a simple peak detector for monitoring the voltage, a fast recovery diode should be selected to ensure rapid response to voltage changes. The 100nF capacitor acts as a charge storage element, allowing the peak voltage to be captured and held for measurement. The high-impedance multimeter is crucial for accurately measuring the average DC voltage across the capacitor without significantly loading the circuit, which could skew the readings.

For practical implementation, the peak detector circuit can be connected in parallel with the battery terminals. The output from the capacitor can then be routed to the multimeter. Regular monitoring of the voltage across the capacitor will provide a clear indication of the progress of the desulphation process. As the treatment continues and the voltage approaches zero, the effectiveness of the desulphation process can be confirmed, indicating that the battery is likely to regain its capacity. This method provides a straightforward and effective means of assessing the treatment without the need for more sophisticated equipment.A number of readers have asked how to tell when the Lead-Acid Battery Zapper has done its job and battery desulphation is complete. In the author`s experience, batteries that are going to respond to this treatment will generally show quite a high peak voltage across the terminals at the beginning of the treatment.

If this steadily decreases and pr actically disappears, then the treatment is near to complete. This may take anything from a week to many months, depending on the size and condition of the battery. In the absence of an oscilloscope to monitor the voltage peaks, a simple peak detector can be constructed from a fast diode and 100nF capacitor.

Any high-impedance multimeter (eg, most digital types) can then be used to measure the average DC voltage across the capacitor. 🔗 External reference

The Lead-Acid Battery Zapper is a device designed to restore the capacity of lead-acid batteries through a process known as desulphation. During this process, sulfation—a common issue where lead sulfate crystals build up on the battery plates—can be reversed. The initial high peak voltage observed at the terminals serves as an indicator of the battery's state prior to treatment. As the desulphation progresses, the steady decline in peak voltage reflects the reduction of sulfation, ultimately leading to improved battery performance.

To construct a simple peak detector for monitoring the voltage, a fast recovery diode should be selected to ensure rapid response to voltage changes. The 100nF capacitor acts as a charge storage element, allowing the peak voltage to be captured and held for measurement. The high-impedance multimeter is crucial for accurately measuring the average DC voltage across the capacitor without significantly loading the circuit, which could skew the readings.

For practical implementation, the peak detector circuit can be connected in parallel with the battery terminals. The output from the capacitor can then be routed to the multimeter. Regular monitoring of the voltage across the capacitor will provide a clear indication of the progress of the desulphation process. As the treatment continues and the voltage approaches zero, the effectiveness of the desulphation process can be confirmed, indicating that the battery is likely to regain its capacity. This method provides a straightforward and effective means of assessing the treatment without the need for more sophisticated equipment.A number of readers have asked how to tell when the Lead-Acid Battery Zapper has done its job and battery desulphation is complete. In the author`s experience, batteries that are going to respond to this treatment will generally show quite a high peak voltage across the terminals at the beginning of the treatment.

If this steadily decreases and pr actically disappears, then the treatment is near to complete. This may take anything from a week to many months, depending on the size and condition of the battery. In the absence of an oscilloscope to monitor the voltage peaks, a simple peak detector can be constructed from a fast diode and 100nF capacitor.

Any high-impedance multimeter (eg, most digital types) can then be used to measure the average DC voltage across the capacitor. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713