Battery Indicator

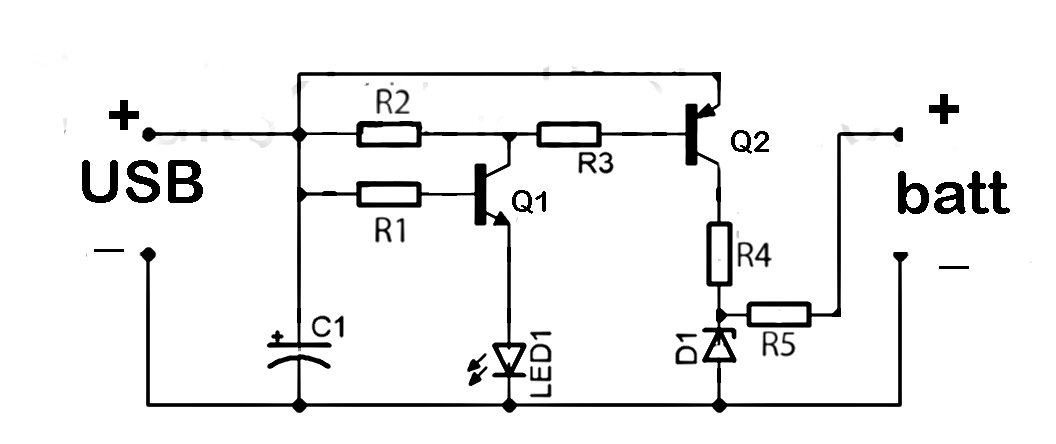

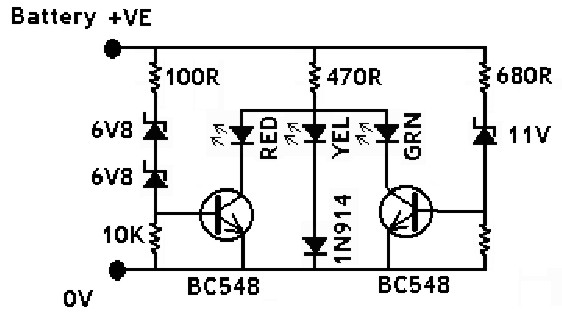

The IN914 (small glass diode) and the zener diodes have bands on their bodies that must be oriented according to the diagram provided. The bands are located at the cathode end of the diodes. A magnifying glass can assist in locating the bands and verifying the values of the zeners. To identify the diodes, the following procedure can be utilized: using a magnifying glass, locate the diode marked with the code IN4148 on the glass surface. This diode is the silicon diode commonly referred to as IN914, and it is not a zener. The zener diodes may have their voltage ratings printed on the side or may display numerical codes. It is important to note that there are two 6.8V zeners and one 11V zener, totaling four diodes. The Molex pins are utilized to connect wires to the circuit; these should be inserted into their respective holes and soldered. The red and black hook-up wires should be stripped, tinned, and soldered to the pins, with red indicating positive and black indicating negative. The circuit should be connected to a power supply with variable voltage control, ensuring correct polarity. The voltage can then be increased while monitoring the circuit's performance against specified figures. This circuit's operation relies on the varying voltage drops across different colored LEDs. At 20mA, the voltage drops across red, yellow, and green LEDs are typically 1.7V, 3.0V, and 2.3V, respectively. When the vehicle battery voltage is insufficient to allow ZD1/ZD2 or ZD3 to conduct, transistors Q1 and Q2 remain off due to resistors R3 and R5. In this state, the yellow LED is forward-biased and conducts through D1, producing approximately 3.7V at the "A legs" of the LEDs. As the supply voltage exceeds approximately 11.6V, ZD3 begins to conduct, activating Q2. Due to its lower voltage requirements, the green LED conducts, which reduces the voltage at the "A legs" of the LEDs to about 2.6V. This voltage is insufficient to forward-bias D1/LED2, resulting in the yellow LED turning off as the green LED takes over its bias. When the supply voltage rises above approximately 14.2V, Q1 is activated, and the red LED takes over the bias from the green LED, causing the potential at the "A legs" of the LEDs to drop to 2V, at which point only the red LED conducts.

The circuit described employs several crucial components including the IN914 diode, zener diodes, and various colored LEDs, each serving a specific function in the overall operation. The IN914 diode, a standard silicon diode, acts as a rectifier, ensuring current flows in one direction. The zener diodes provide voltage regulation, allowing for stable operation across varying input voltages. The use of different colored LEDs allows for visual feedback corresponding to the voltage levels detected within the circuit.

The transistors Q1 and Q2 play a vital role in controlling the LED states based on the input voltage. Resistors R3 and R5 are essential for setting the biasing conditions of these transistors, ensuring that they only conduct when the input voltage reaches certain thresholds. The feedback mechanism involving the LEDs allows for a clear indication of the circuit's operational state, with the yellow LED indicating low voltage conditions, the green LED indicating an intermediate voltage range, and the red LED representing high voltage conditions.

The circuit's design emphasizes efficiency and reliability, utilizing components that are readily available and easy to implement. The careful selection of voltage thresholds for the zener diodes and the corresponding LED behaviors ensures that the circuit operates effectively across a range of input conditions, making it suitable for applications in vehicle battery monitoring systems and other similar electronic projects. This comprehensive arrangement of components and their interactions illustrates a well-thought-out schematic that balances functionality with simplicity.The IN914 (little glassy diode) and the zener diodes all have bands on the body which must be put in the direction shown on the drawing. The bands ar ` e at the K end of the diodes. A magnifying glass will help to locate the bands and also to check the values of the zeners. To identify them, the following procedure will help : with a magnifying glass find the diode that` has the code IN4148 printed on the glassy surface. This is the silicon diode usually referred to as IN914, NOT a zener. The zeners may have their voltage printed on the side, or they may have numbers. Remember that there are two 6V8 zeners and one 11V, so 4. The molex pins are to connect the wires to the circuit. Push them through in their holes and solder. Bare the Red and Black hook-up wires, tin them and solder to the pins. Red is Positive, Black Negative 5. Connect the circuit to a power supply with a variable Voltage control, but make sure the polarity is co ect. Wind up the voltage and check the performance of your circuit against the quoted performance figures.

This circuit depends for its operation upon the different voltage drops across different colour LEDs. At 20mA the voltage drops across red, yellow and green LEDs are typically 1. 7, 3. 0 and 2. 3 volts respectively. When the vehicle battery voltage is too low to cause either ZDI/ZD2 or ZD3 to conduct, Q1 and 02 are held off by R3 and R5.

Under these conditions the yellow LED is forward biased and conducts `via D1 producing a potential of about 3. 7 volts at the "A legs" of the LED`s. When the supply rises above about 11. 6 volts ZD3 conducts, biasing Q2 on. By virtue of its lower voltage recuirements the green LED conducts, reducing the voltage at the "A legs" of the LED`s to approximately 2.

6 volts. This is not enough to bias DI/LED2 on, so the yellow LED goes off. The green LED `steals` the bias from the yellow LED. When thesupply rises above about 14. 2 volts, Q1 is biased on and the red LED `steals` the bias from the green. The potential at the "A legs" of the LED`s falls to two volts and only thered LED conducts. 🔗 External reference

The circuit described employs several crucial components including the IN914 diode, zener diodes, and various colored LEDs, each serving a specific function in the overall operation. The IN914 diode, a standard silicon diode, acts as a rectifier, ensuring current flows in one direction. The zener diodes provide voltage regulation, allowing for stable operation across varying input voltages. The use of different colored LEDs allows for visual feedback corresponding to the voltage levels detected within the circuit.

The transistors Q1 and Q2 play a vital role in controlling the LED states based on the input voltage. Resistors R3 and R5 are essential for setting the biasing conditions of these transistors, ensuring that they only conduct when the input voltage reaches certain thresholds. The feedback mechanism involving the LEDs allows for a clear indication of the circuit's operational state, with the yellow LED indicating low voltage conditions, the green LED indicating an intermediate voltage range, and the red LED representing high voltage conditions.

The circuit's design emphasizes efficiency and reliability, utilizing components that are readily available and easy to implement. The careful selection of voltage thresholds for the zener diodes and the corresponding LED behaviors ensures that the circuit operates effectively across a range of input conditions, making it suitable for applications in vehicle battery monitoring systems and other similar electronic projects. This comprehensive arrangement of components and their interactions illustrates a well-thought-out schematic that balances functionality with simplicity.The IN914 (little glassy diode) and the zener diodes all have bands on the body which must be put in the direction shown on the drawing. The bands ar ` e at the K end of the diodes. A magnifying glass will help to locate the bands and also to check the values of the zeners. To identify them, the following procedure will help : with a magnifying glass find the diode that` has the code IN4148 printed on the glassy surface. This is the silicon diode usually referred to as IN914, NOT a zener. The zeners may have their voltage printed on the side, or they may have numbers. Remember that there are two 6V8 zeners and one 11V, so 4. The molex pins are to connect the wires to the circuit. Push them through in their holes and solder. Bare the Red and Black hook-up wires, tin them and solder to the pins. Red is Positive, Black Negative 5. Connect the circuit to a power supply with a variable Voltage control, but make sure the polarity is co ect. Wind up the voltage and check the performance of your circuit against the quoted performance figures.

This circuit depends for its operation upon the different voltage drops across different colour LEDs. At 20mA the voltage drops across red, yellow and green LEDs are typically 1. 7, 3. 0 and 2. 3 volts respectively. When the vehicle battery voltage is too low to cause either ZDI/ZD2 or ZD3 to conduct, Q1 and 02 are held off by R3 and R5.

Under these conditions the yellow LED is forward biased and conducts `via D1 producing a potential of about 3. 7 volts at the "A legs" of the LED`s. When the supply rises above about 11. 6 volts ZD3 conducts, biasing Q2 on. By virtue of its lower voltage recuirements the green LED conducts, reducing the voltage at the "A legs" of the LED`s to approximately 2.

6 volts. This is not enough to bias DI/LED2 on, so the yellow LED goes off. The green LED `steals` the bias from the yellow LED. When thesupply rises above about 14. 2 volts, Q1 is biased on and the red LED `steals` the bias from the green. The potential at the "A legs" of the LED`s falls to two volts and only thered LED conducts. 🔗 External reference