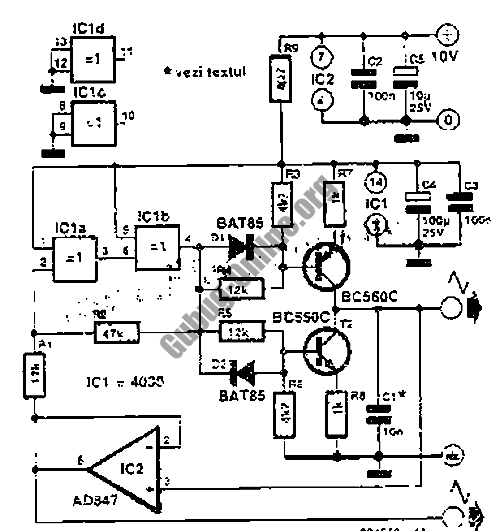

boost converter circuit for digital

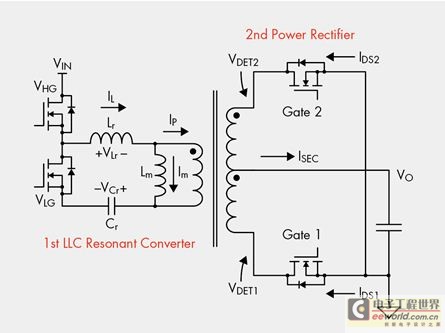

This design circuit serves as a converter utilizing the LM2623A ratio adaptive circuit to drive a digital camera motor. It generates 5 volts from input voltages that range between 1.8 and 4.5 volts. The circuit's duty cycle, while not explicitly shown, varies from approximately 86% at an input of 1.8 volts to 71% at an input of 4.5 volts. Maintaining an 86% duty cycle at 4.5 volts would lead to reduced efficiency and increased ripple, while sustaining a 70% duty cycle at 1.8 volts would significantly limit the output capability. Numerous camera manufacturers now mandate operation within the 1.8 to 4.5-volt range for all power supplies. This voltage standard enables manufacturers to design products that allow users to choose between disposable alkaline batteries, Ni-MH, or Li-Ion options at the point of purchase.

The LM2623A is a highly efficient DC-DC converter designed for low-voltage applications, making it well-suited for driving motors in digital cameras. The circuit configuration typically involves a switching regulator topology, which allows for efficient voltage conversion while minimizing power loss. The input voltage range of 1.8 to 4.5 volts is critical, as it accommodates various battery chemistries, including alkaline, nickel-metal hydride (Ni-MH), and lithium-ion (Li-Ion) cells.

The duty cycle of the converter is a crucial parameter that affects both the output voltage and the efficiency of the circuit. At lower input voltages, such as 1.8 volts, a higher duty cycle (86%) is required to maintain the desired output voltage of 5 volts. However, operating at this duty cycle can lead to increased ripple voltage, which may negatively impact the performance of sensitive electronic components, such as those found in digital cameras.

Conversely, at higher input voltages, such as 4.5 volts, the duty cycle decreases to 71%. While this lower duty cycle improves efficiency and reduces ripple, it also limits the output capability of the converter. Therefore, careful consideration must be given to the design parameters to ensure that the circuit meets the operational requirements of the digital camera motor under varying input conditions.

To enhance the performance of this circuit, additional components such as input and output capacitors, inductors, and feedback resistors may be incorporated. Input capacitors help to stabilize the input voltage and reduce voltage spikes, while output capacitors smooth out the voltage delivered to the motor, minimizing ripple. The inductor plays a vital role in energy storage during the switching cycle, and the feedback resistors are essential for regulating the output voltage by providing feedback to the control circuitry.

Overall, the LM2623A-based converter circuit is a practical solution for powering digital camera motors, ensuring compatibility with a range of battery types while maintaining efficiency and performance across its specified input voltage range.This is a design circuit for converter that using for a very practical LM2623A ratio adaptive circuit to drive a digital camera motor. It produces 5 volts from input voltages ranging between 1. 8 and 4. 5 volts. This is the figure of the circuit; The duty cycle is not shown, but it varies from about 86% at 1. 8 volts in to 71% at 4. 5 volts in. Mainta ining the 86% duty cycle at 4. 5 volts would reduce the efficiency and increase the ripple. Maintaining the 70% duty cycle at 1. 8 volts would significantly reduce the output capability. Several camera manufacturers are already requiring 1. 8 to 4. 5 volt operation from all the power supplies. The 1. 8 to 4. 5 voltage standard allows a manufacturer to build his product and let the user select disposable Alkalines, Ni-MH or Li-Ion at the point of purchase. 🔗 External reference

The LM2623A is a highly efficient DC-DC converter designed for low-voltage applications, making it well-suited for driving motors in digital cameras. The circuit configuration typically involves a switching regulator topology, which allows for efficient voltage conversion while minimizing power loss. The input voltage range of 1.8 to 4.5 volts is critical, as it accommodates various battery chemistries, including alkaline, nickel-metal hydride (Ni-MH), and lithium-ion (Li-Ion) cells.

The duty cycle of the converter is a crucial parameter that affects both the output voltage and the efficiency of the circuit. At lower input voltages, such as 1.8 volts, a higher duty cycle (86%) is required to maintain the desired output voltage of 5 volts. However, operating at this duty cycle can lead to increased ripple voltage, which may negatively impact the performance of sensitive electronic components, such as those found in digital cameras.

Conversely, at higher input voltages, such as 4.5 volts, the duty cycle decreases to 71%. While this lower duty cycle improves efficiency and reduces ripple, it also limits the output capability of the converter. Therefore, careful consideration must be given to the design parameters to ensure that the circuit meets the operational requirements of the digital camera motor under varying input conditions.

To enhance the performance of this circuit, additional components such as input and output capacitors, inductors, and feedback resistors may be incorporated. Input capacitors help to stabilize the input voltage and reduce voltage spikes, while output capacitors smooth out the voltage delivered to the motor, minimizing ripple. The inductor plays a vital role in energy storage during the switching cycle, and the feedback resistors are essential for regulating the output voltage by providing feedback to the control circuitry.

Overall, the LM2623A-based converter circuit is a practical solution for powering digital camera motors, ensuring compatibility with a range of battery types while maintaining efficiency and performance across its specified input voltage range.This is a design circuit for converter that using for a very practical LM2623A ratio adaptive circuit to drive a digital camera motor. It produces 5 volts from input voltages ranging between 1. 8 and 4. 5 volts. This is the figure of the circuit; The duty cycle is not shown, but it varies from about 86% at 1. 8 volts in to 71% at 4. 5 volts in. Mainta ining the 86% duty cycle at 4. 5 volts would reduce the efficiency and increase the ripple. Maintaining the 70% duty cycle at 1. 8 volts would significantly reduce the output capability. Several camera manufacturers are already requiring 1. 8 to 4. 5 volt operation from all the power supplies. The 1. 8 to 4. 5 voltage standard allows a manufacturer to build his product and let the user select disposable Alkalines, Ni-MH or Li-Ion at the point of purchase. 🔗 External reference