Car Battery Charger12V circuit and explanation

All car batteries require a 12V battery charger, which also applies to marine, RV, and power sports batteries. The high-efficiency lead-acid batteries available today necessitate more effective charging techniques. The battery charger is a crucial tool for prolonging battery life, ensuring that the battery is operational and reducing downtime. Using the appropriate charger is vital, as some manufacturers of gel cell, solar, and AGM batteries may void warranties if the correct charger or a 12V gel cell charger is not utilized. With advancements in battery technology, microprocessor technology has been integrated into many high-quality battery chargers, transforming battery charging into a precise science. These chargers prevent overcharging and consistently maintain a trickle charge, offering fully automatic operation with float mode monitoring capabilities and high-frequency power conversion technology.

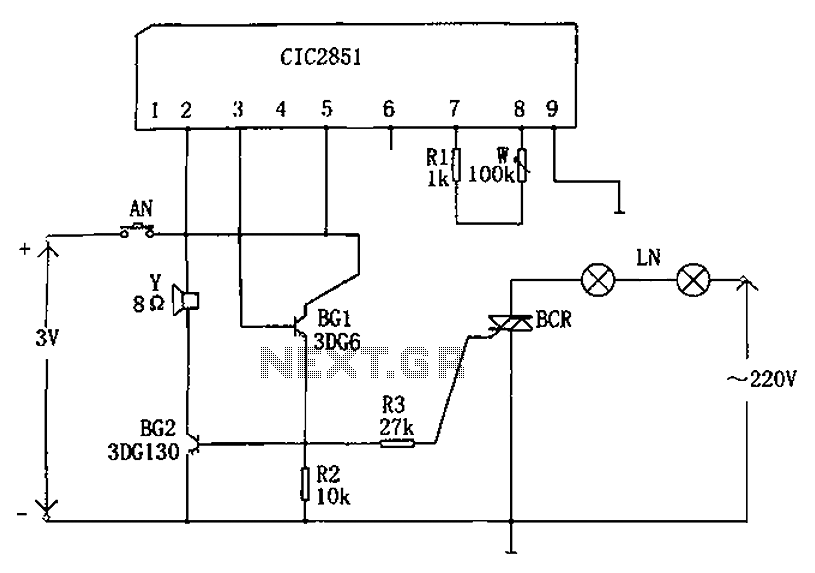

Most conventional car battery chargers are basic devices that provide a continuous charge of a few amperes while active. However, if a charger is not switched off in time, it can lead to overcharging, electrolyte evaporation, and potential damage to the plate elements. The 12V car battery charger circuit described below addresses these issues by monitoring the battery's charge condition through a retroactive control circuit that applies a high charge current until the battery is fully charged. Upon completion of charging, a red LED (LD2) activates, and the charging circuit is deactivated. This circuit is specifically designed for charging 12V batteries, and careful attention must be paid to the wiring connections, particularly those linking the transformer to the circuit board and those supplying current to the battery. It is recommended that these connections utilize cables with a large cross-sectional area to minimize voltage drop and heat buildup during current flow. This battery charger is capable of charging any 12V lead-acid battery, including flooded, gel, and AGM types. It operates automatically, charging at a rate of up to approximately 4A until the battery voltage reaches a predetermined threshold, at which point it switches to a low current float charge. If the battery voltage decreases again, the charger resumes charging until the voltage reaches the cutoff point. This design allows for indefinite connection to the battery, maintaining full charge without risk of damage. An LED indicator signals when the battery is fully charged.

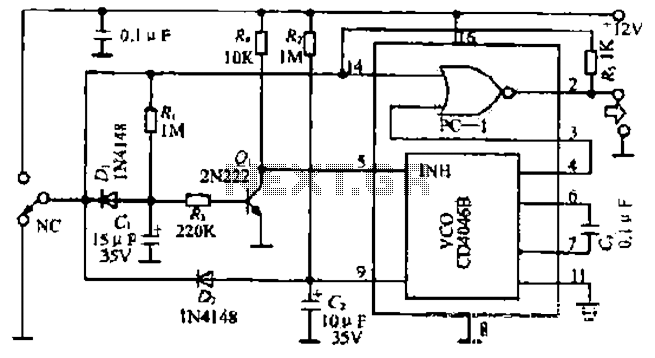

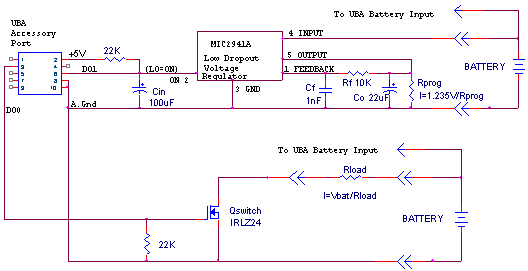

The circuit design for the 12V battery charger incorporates several key components, including a transformer, a rectifier, filter capacitors, a microcontroller, and output circuitry. The transformer steps down the AC voltage to an appropriate level for charging. The rectifier converts the AC voltage to DC, which is then smoothed by filter capacitors to provide a stable voltage output. The microcontroller monitors the battery voltage, controlling the charging process by adjusting the current output based on the battery's state of charge. This intelligent control prevents overcharging and optimizes charging efficiency.

The circuit also includes protection features such as fuses and thermal cutoffs to safeguard against overcurrent and overheating conditions. These additional safety measures enhance the reliability of the charger, ensuring that it can be used safely over extended periods. The incorporation of an LED indicator not only serves as a visual cue for the charging status but also aids in user interaction, allowing for easy monitoring of the battery's condition.

Overall, this 12V battery charger circuit exemplifies modern advancements in battery charging technology, providing a robust and efficient solution for maintaining various types of lead-acid batteries while ensuring longevity and performance.All car batteries have required a 12v battery charger. And this is also true of Marine, RV and Power Sports batteries. The high efficiency lead acid type batteries available today require more efficient charging techniques. The most important factors in the life of your battery, the battery charger is the most valuable tool in saving the life of y

our battery, getting up and running and cutting your down time. Using the proper charger is crucial to your battery. Some manufacturers of gel cell, solar and AGM batteries will not honor warranties if the proper charger or 12 volt gel cell charger is not used. With the change of battery technology the computer chip has found its way into many of the higher quality battery chargers.

With the use of microprocessor technology in battery chargers, you could say battery charging has become a science. Your battery will never overcharge and the trickle charge will always be maintained. It is fully automatic with float mode monitoring capabilities and uses high-frequency power conversion technology.

Most car battery chargers are simple devices that continuously charge the battery with a few amperes for the duration it is ON. If the charger is not switched OFF in time, the battery will overcharge, its electrolyte lost due to evaporation, and its plate-element will likely be destroyed.

The 12 volt car battery charger circuit below will eliminate these problems by monitoring the batteries condition of charge through its retroactive control circuit by applying a high charge current until the battery is completely charged. When charging is complete, it turns on the red LED (LD2) and deactivates the charging circuit. This circuit is drawn to charge 12V batteries ONLY. Certain emphasis should be taken when wiring up this circuit. They are the connections of the transformer to the circuit board, and those supplying current to the battery being charged.

These connections should be made with cables having a large cross-sectional area to prevent voltage-drop and heat build-up when current flows through them. See This battery charger will charge any 12V lead acid battery including flooded, gel and AGM. It is fully automatic and will charge at a rate up to about 4A until the battery voltage reaches a preset point at which it will switch to a very low current float charge.

If the battery voltage drops again the charger will begin charging until the voltage once again reaches the cut off point. In this way it can be left connected to a battery indefinitely to maintain full charge without causing damage.

An LED indicates when the battery is fully charged. 🔗 External reference

Most conventional car battery chargers are basic devices that provide a continuous charge of a few amperes while active. However, if a charger is not switched off in time, it can lead to overcharging, electrolyte evaporation, and potential damage to the plate elements. The 12V car battery charger circuit described below addresses these issues by monitoring the battery's charge condition through a retroactive control circuit that applies a high charge current until the battery is fully charged. Upon completion of charging, a red LED (LD2) activates, and the charging circuit is deactivated. This circuit is specifically designed for charging 12V batteries, and careful attention must be paid to the wiring connections, particularly those linking the transformer to the circuit board and those supplying current to the battery. It is recommended that these connections utilize cables with a large cross-sectional area to minimize voltage drop and heat buildup during current flow. This battery charger is capable of charging any 12V lead-acid battery, including flooded, gel, and AGM types. It operates automatically, charging at a rate of up to approximately 4A until the battery voltage reaches a predetermined threshold, at which point it switches to a low current float charge. If the battery voltage decreases again, the charger resumes charging until the voltage reaches the cutoff point. This design allows for indefinite connection to the battery, maintaining full charge without risk of damage. An LED indicator signals when the battery is fully charged.

The circuit design for the 12V battery charger incorporates several key components, including a transformer, a rectifier, filter capacitors, a microcontroller, and output circuitry. The transformer steps down the AC voltage to an appropriate level for charging. The rectifier converts the AC voltage to DC, which is then smoothed by filter capacitors to provide a stable voltage output. The microcontroller monitors the battery voltage, controlling the charging process by adjusting the current output based on the battery's state of charge. This intelligent control prevents overcharging and optimizes charging efficiency.

The circuit also includes protection features such as fuses and thermal cutoffs to safeguard against overcurrent and overheating conditions. These additional safety measures enhance the reliability of the charger, ensuring that it can be used safely over extended periods. The incorporation of an LED indicator not only serves as a visual cue for the charging status but also aids in user interaction, allowing for easy monitoring of the battery's condition.

Overall, this 12V battery charger circuit exemplifies modern advancements in battery charging technology, providing a robust and efficient solution for maintaining various types of lead-acid batteries while ensuring longevity and performance.All car batteries have required a 12v battery charger. And this is also true of Marine, RV and Power Sports batteries. The high efficiency lead acid type batteries available today require more efficient charging techniques. The most important factors in the life of your battery, the battery charger is the most valuable tool in saving the life of y

our battery, getting up and running and cutting your down time. Using the proper charger is crucial to your battery. Some manufacturers of gel cell, solar and AGM batteries will not honor warranties if the proper charger or 12 volt gel cell charger is not used. With the change of battery technology the computer chip has found its way into many of the higher quality battery chargers.

With the use of microprocessor technology in battery chargers, you could say battery charging has become a science. Your battery will never overcharge and the trickle charge will always be maintained. It is fully automatic with float mode monitoring capabilities and uses high-frequency power conversion technology.

Most car battery chargers are simple devices that continuously charge the battery with a few amperes for the duration it is ON. If the charger is not switched OFF in time, the battery will overcharge, its electrolyte lost due to evaporation, and its plate-element will likely be destroyed.

The 12 volt car battery charger circuit below will eliminate these problems by monitoring the batteries condition of charge through its retroactive control circuit by applying a high charge current until the battery is completely charged. When charging is complete, it turns on the red LED (LD2) and deactivates the charging circuit. This circuit is drawn to charge 12V batteries ONLY. Certain emphasis should be taken when wiring up this circuit. They are the connections of the transformer to the circuit board, and those supplying current to the battery being charged.

These connections should be made with cables having a large cross-sectional area to prevent voltage-drop and heat build-up when current flows through them. See This battery charger will charge any 12V lead acid battery including flooded, gel and AGM. It is fully automatic and will charge at a rate up to about 4A until the battery voltage reaches a preset point at which it will switch to a very low current float charge.

If the battery voltage drops again the charger will begin charging until the voltage once again reaches the cut off point. In this way it can be left connected to a battery indefinitely to maintain full charge without causing damage.

An LED indicates when the battery is fully charged. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713