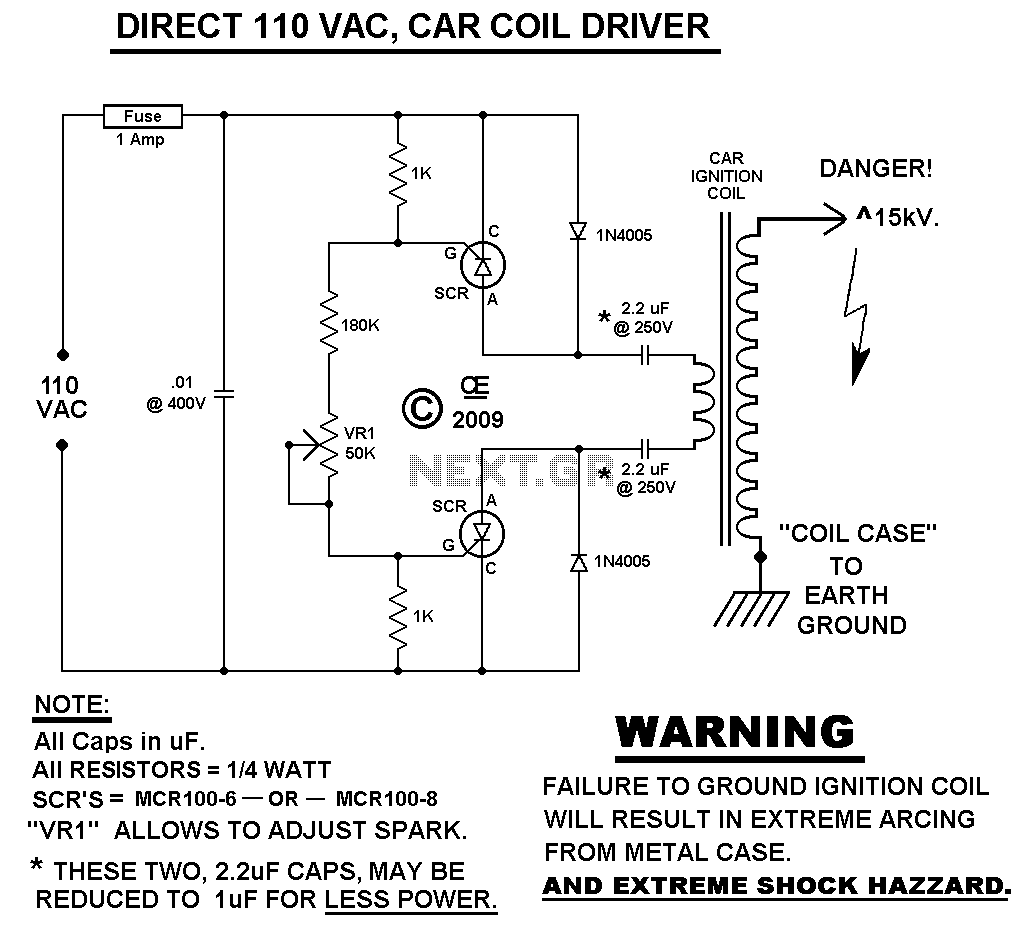

Car Ignition Coil Driver gives 15kV

This Spark Can Be Very DANGEROUS, So BE CAREFUL. WARNING: FAILURE TO DO SO: WILL CAUSE THE CASE OF THE COIL TO ALSO BE ELECTRIFIED! NOTE You MUST have a LOAD on the High Voltage Output. With NO LOAD, you have a High Risk to "Damage the Ignition Coil". Either a Spark Gap or a High Resistive Load is suitable. A 220 or 240 VAC @ 50 Hz Version is Definately Possible. Sorry but I don't have that AC power source to test one out. Lastly, If you Build this circuit, Its at your own Risk. I Will Not accept responsibility for what you do!

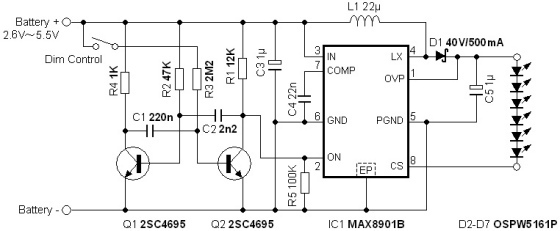

The circuit described involves a high-voltage ignition coil, which is commonly used in applications such as gas engines or other ignition systems. The ignition coil transforms low voltage from a power source into a high voltage, which is necessary for creating an electric spark to ignite fuel.

To ensure safe operation, it is crucial to have a load connected to the high-voltage output of the ignition coil. This load can be a spark gap or a high-resistive load, which helps to prevent damage to the coil. Without a load, the coil may become energized without a path for the current to flow, leading to a risk of damage and potential hazards, including electrification of the coil's casing.

For applications operating at 220 or 240 VAC at 50 Hz, the circuit must be designed to handle the specific voltage and frequency. Components such as resistors, capacitors, and diodes should be selected based on their voltage ratings and power handling capabilities to ensure they can withstand the high voltages generated by the ignition coil.

Safety precautions are paramount when working with high-voltage circuits. Proper insulation and protective equipment should be utilized to prevent accidental contact with live parts. Additionally, the circuit should be housed in a non-conductive enclosure to further reduce the risk of electric shock.

It is essential to emphasize that constructing and operating this circuit is done at the builder's own risk. Adequate knowledge and understanding of high-voltage electronics are necessary to ensure safe and effective operation.This Spark Can Be Very DANGEROUS, So BE CAREFUL. WARNING: FAILURE TO DO SO: WILL CAUSE THE CASE OF THE COIL TO ALSO BE ELECTRIFIED! NOTE You MUST have a LOAD on the High Voltage Output. With NO LOAD, you have a High Risk to "Damage the Ignition Coil". Either a Spark Gap or a High Resistive Load is suitable. A 220 or 240 VAC @ 50 Hz Version is Definately Possible. Sorry but I don't have that AC power source to test one out. Lastly, If you Build this circuit, Its at your own Risk. I Will Not accept responsibility for what you do! 🔗 External reference

The circuit described involves a high-voltage ignition coil, which is commonly used in applications such as gas engines or other ignition systems. The ignition coil transforms low voltage from a power source into a high voltage, which is necessary for creating an electric spark to ignite fuel.

To ensure safe operation, it is crucial to have a load connected to the high-voltage output of the ignition coil. This load can be a spark gap or a high-resistive load, which helps to prevent damage to the coil. Without a load, the coil may become energized without a path for the current to flow, leading to a risk of damage and potential hazards, including electrification of the coil's casing.

For applications operating at 220 or 240 VAC at 50 Hz, the circuit must be designed to handle the specific voltage and frequency. Components such as resistors, capacitors, and diodes should be selected based on their voltage ratings and power handling capabilities to ensure they can withstand the high voltages generated by the ignition coil.

Safety precautions are paramount when working with high-voltage circuits. Proper insulation and protective equipment should be utilized to prevent accidental contact with live parts. Additionally, the circuit should be housed in a non-conductive enclosure to further reduce the risk of electric shock.

It is essential to emphasize that constructing and operating this circuit is done at the builder's own risk. Adequate knowledge and understanding of high-voltage electronics are necessary to ensure safe and effective operation.This Spark Can Be Very DANGEROUS, So BE CAREFUL. WARNING: FAILURE TO DO SO: WILL CAUSE THE CASE OF THE COIL TO ALSO BE ELECTRIFIED! NOTE You MUST have a LOAD on the High Voltage Output. With NO LOAD, you have a High Risk to "Damage the Ignition Coil". Either a Spark Gap or a High Resistive Load is suitable. A 220 or 240 VAC @ 50 Hz Version is Definately Possible. Sorry but I don't have that AC power source to test one out. Lastly, If you Build this circuit, Its at your own Risk. I Will Not accept responsibility for what you do! 🔗 External reference